Dust concentration detection equipment

A technology for dust concentration detection and equipment, which is used in measurement devices, suspension and porous material analysis, particle suspension analysis, etc. It can solve problems such as large measurement errors and difficulty in online monitoring of dust concentration, and achieve the effect of avoiding adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

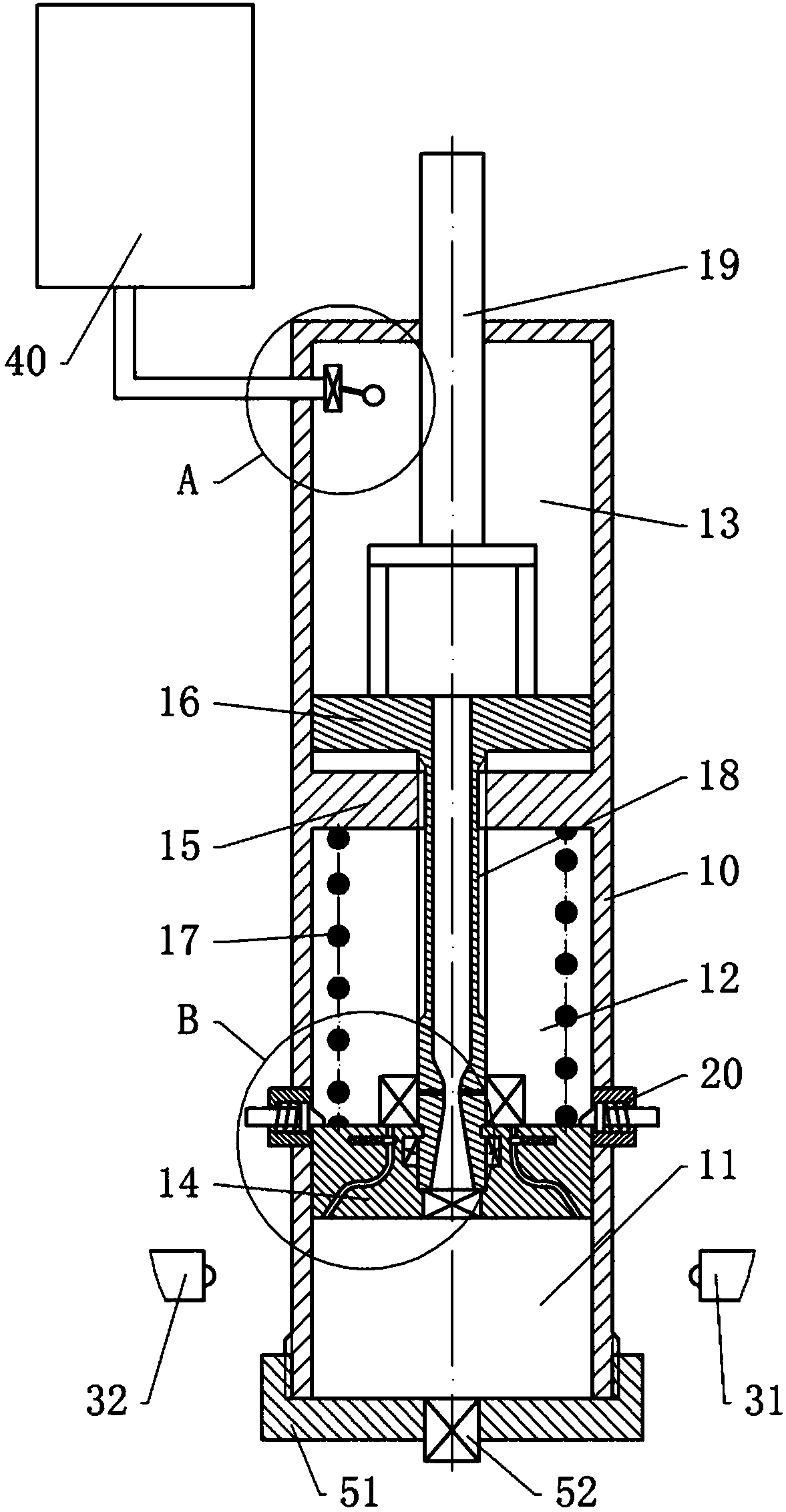

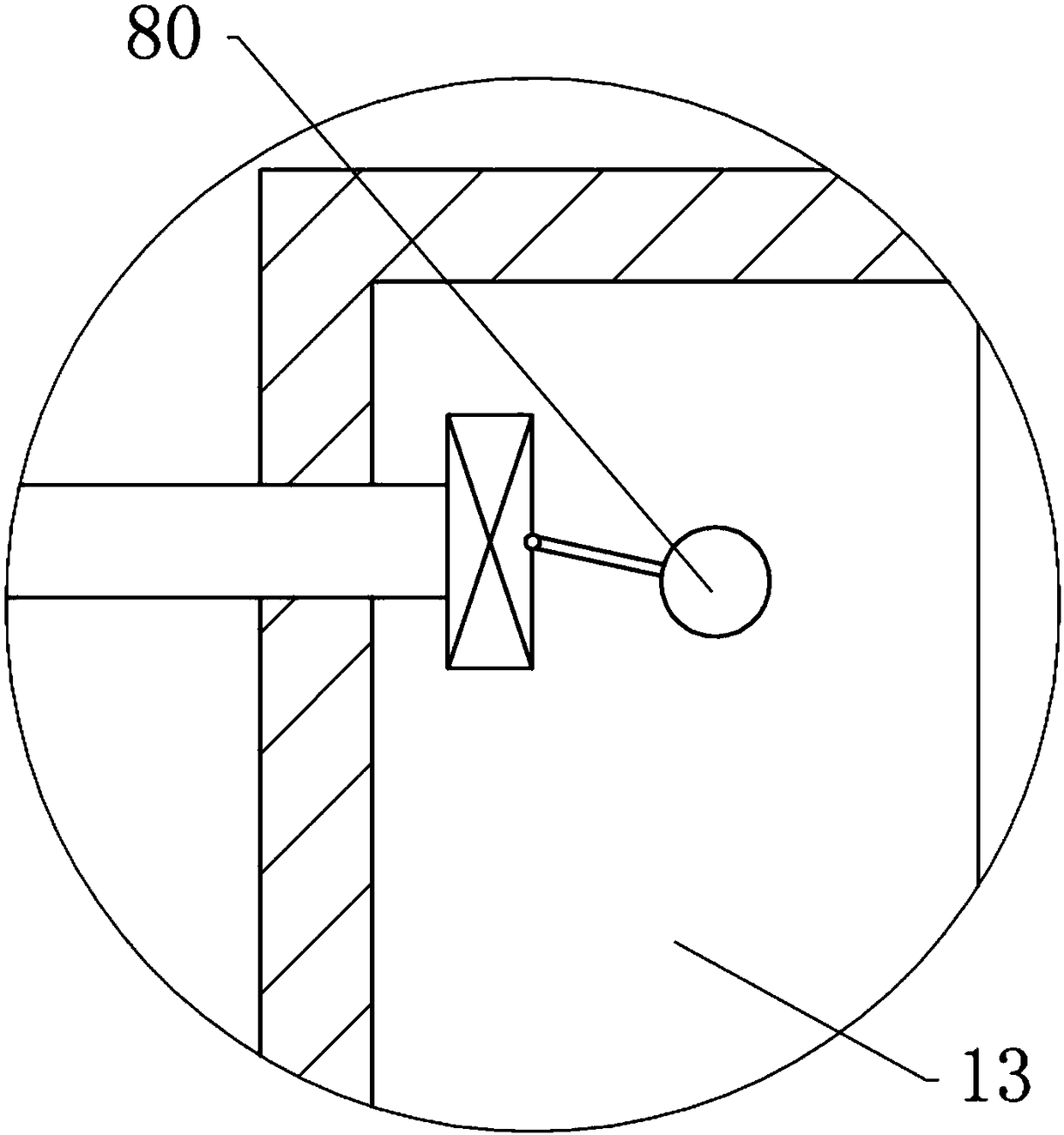

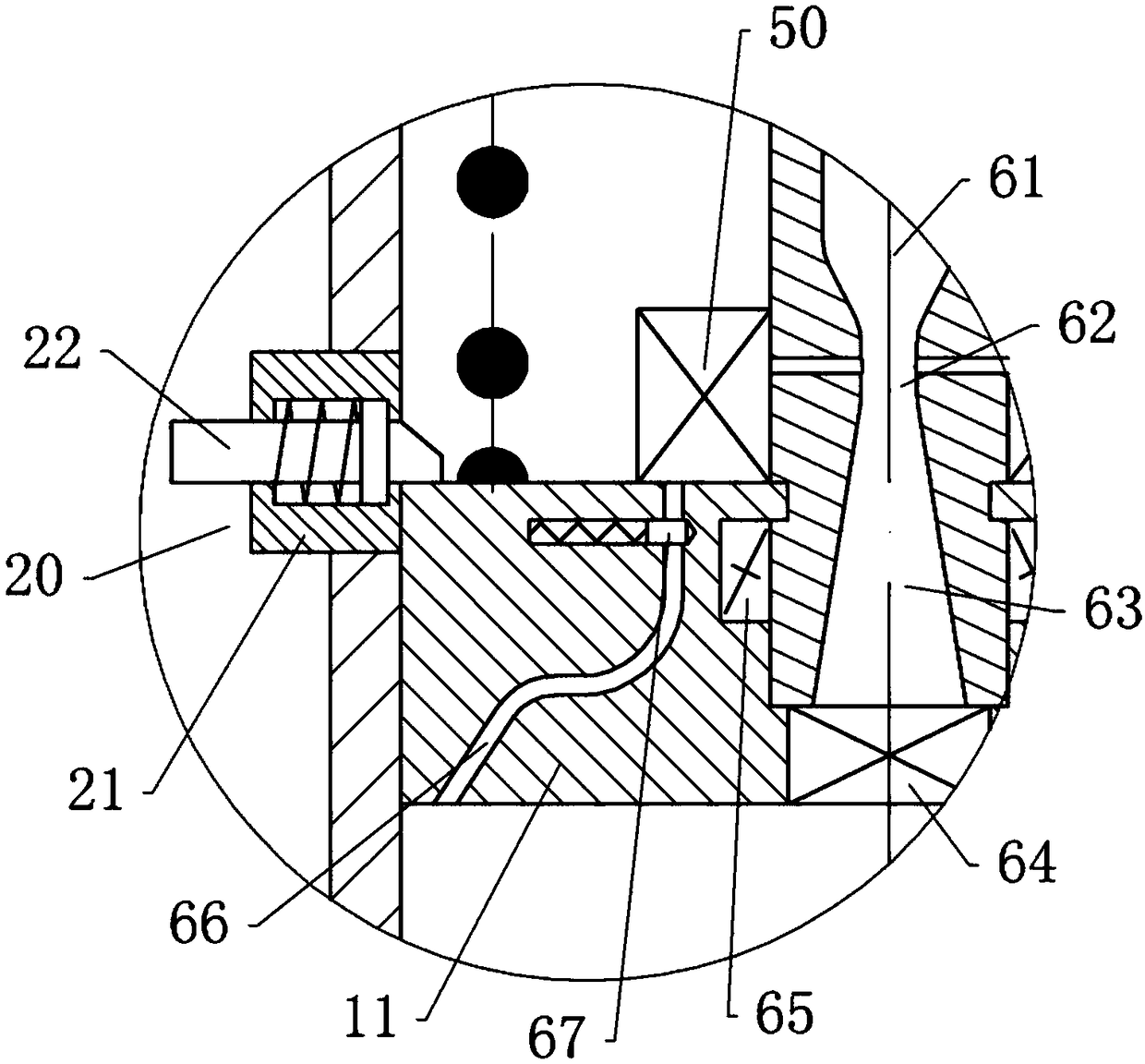

[0026] The reference signs in the drawings of the description include: cylinder 10, detection area 11, vacuum area 12, water storage area 13, first piston 14, partition 15, second piston 16, extension spring 17, connecting rod 18, pressure Rod 19, retractable rod 20, laser emitting end 31, laser receiving end 32, water tank 40, cover body 51, pressure relief valve 52, float switch 80, outer rod 21, inner rod 22, inlet section 61, throat 62, Diffusion section 63 , one-way valve 64 , one-way bearing 65 , suction hole 66 , blocking block 67 , and rotary joint 50 .

[0027] The embodiment is basically as figure 1 , figure 2 and image 3 Shown:

[0028] The dust concentration detecting device of this embodiment includes a compression part, a detection part and a water supply part. The compression part includes a cylindrical cylinder 10 made of tempered glass. The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com