Detecting system and detecting method for apparent defects and internal quality of dam slab

A technology for internal quality and appearance defects, applied in radio wave measurement systems, signal transmission systems, optical testing flaws/defects, etc., can solve problems such as inability to achieve comprehensive monitoring, low efficiency of infrared detection, etc., to improve detection accuracy and Efficiency, saving detection time, and improving the effect of original quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, a preferred embodiment of the present invention will be used to describe the specific implementation of the present invention, but the implementation and protection of the present invention are not limited thereto.

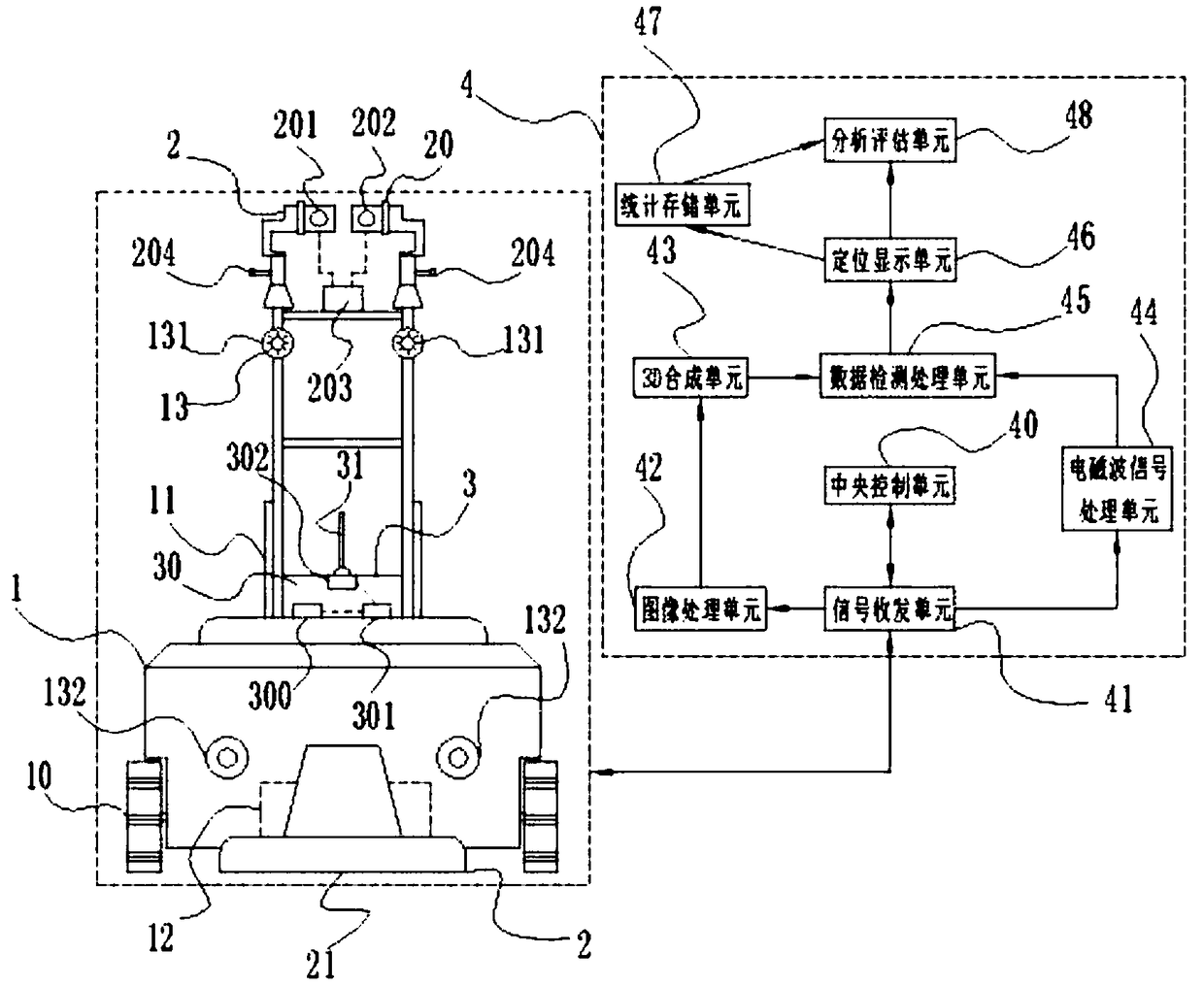

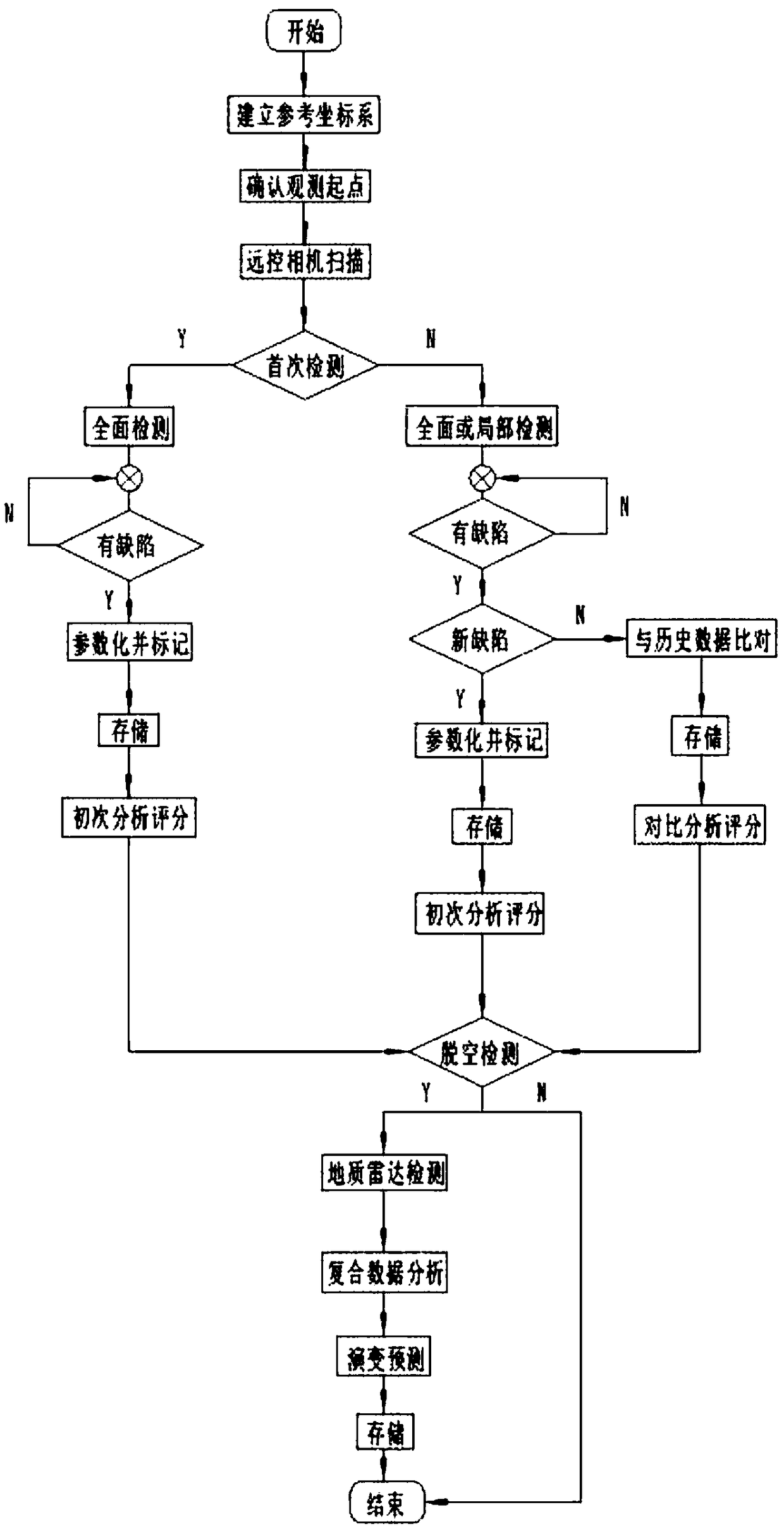

[0029] Such as figure 1 As shown, a detection system for the appearance defect and internal quality of the dam panel includes a mobile base module 1, a defect detection module 2, a wireless transmission module 3, and a remote control module 4; the defect detection module 2 and the wireless transmission module 3 are loaded on On the mobile base module 1, the remote control module 4 remotely controls the mobile base module 1 and the defect detection module 2 through the wireless transmission module 3;

[0030] The mobile base module 1 includes a wheeled vehicle 10, a rotating and lifting platform 11, and a remote control driver 12. The rotating and lifting platform 11 is fixed on the wheeled vehicle 10, and the remote control driver 12 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com