Fault diagnosis method for electromechanical equipment based on gray model

A gray model, electromechanical equipment technology, applied in mechanical equipment, machine/engine, electrical test/monitoring, etc., can solve problems such as environmental pollution, leakage, and threat to the life safety of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

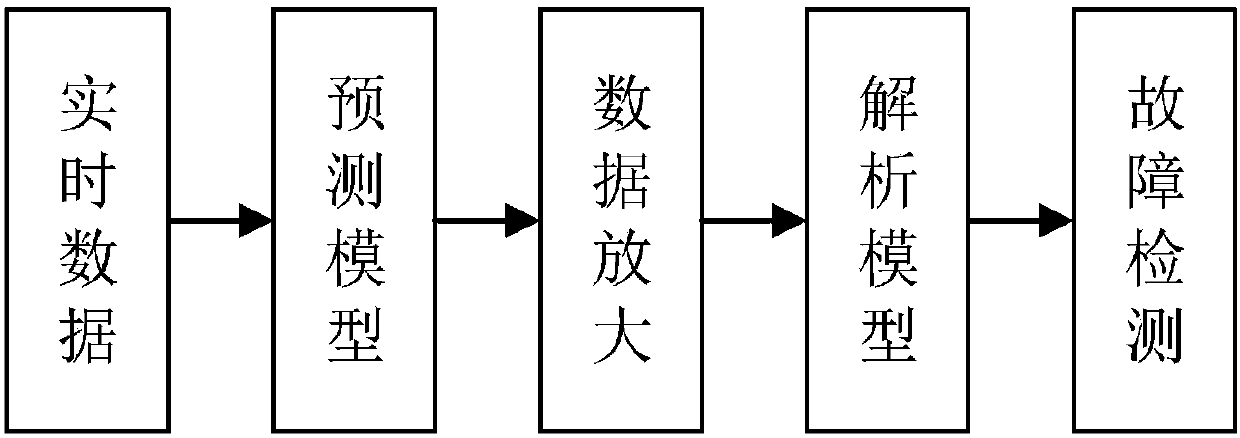

AI Technical Summary

Problems solved by technology

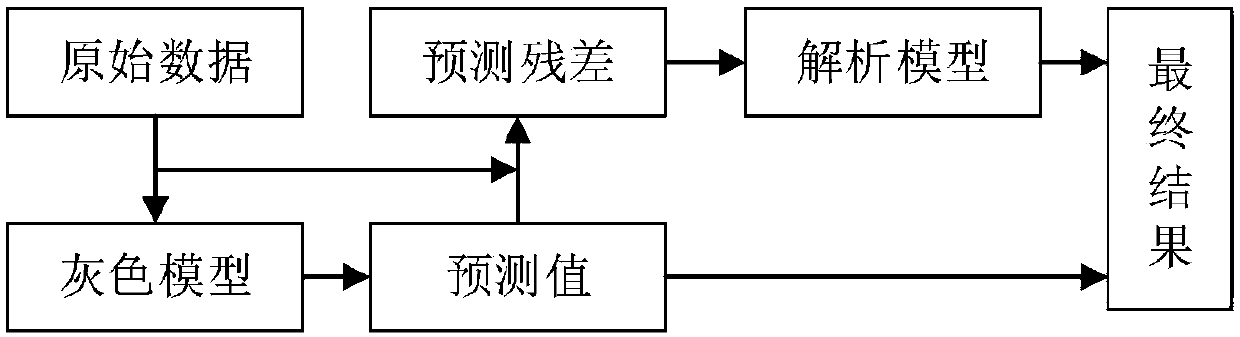

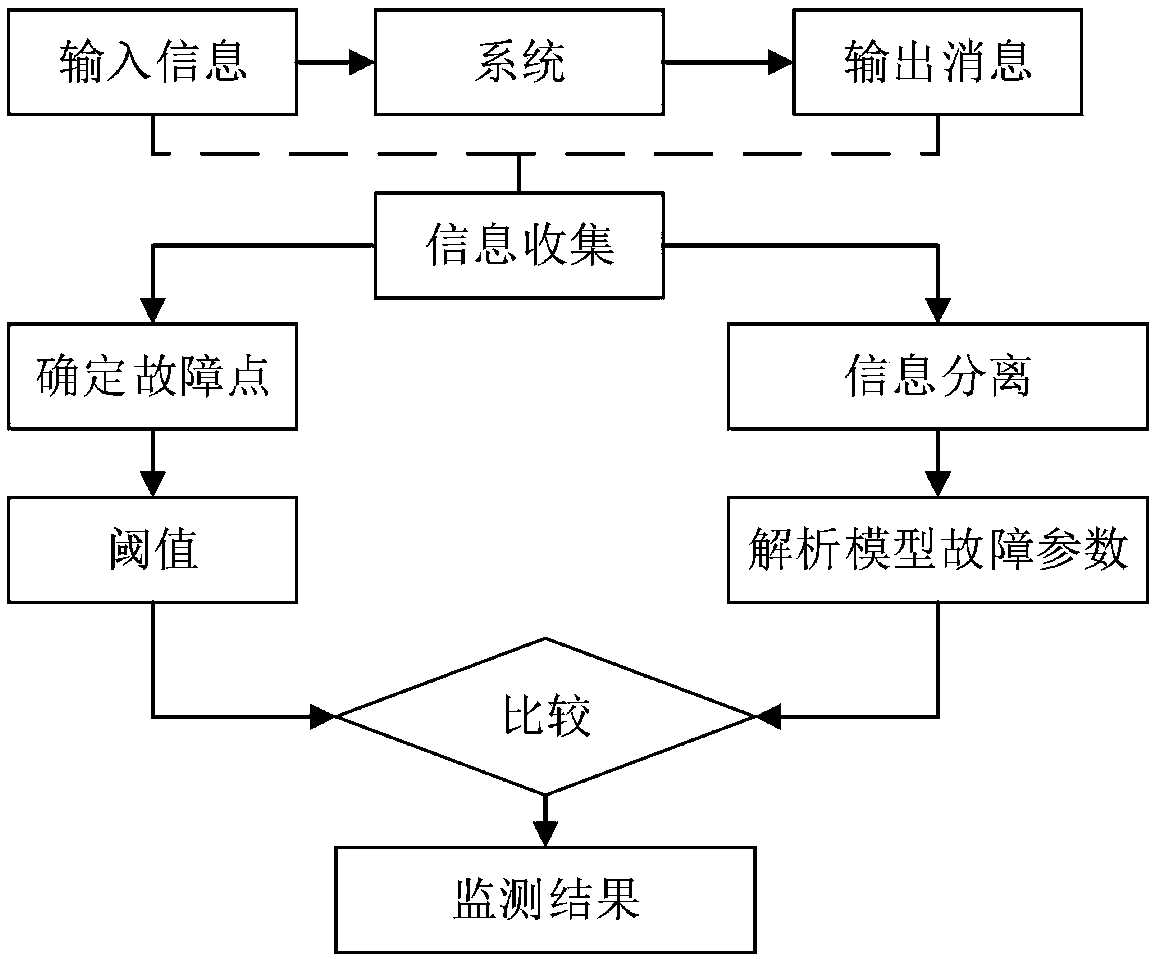

Method used

Image

Examples

Embodiment 1

[0164] Taking the common centrifugal pump and pipeline system in the pipe gallery as an example, the application steps of the research parameter estimation method are as follows:

[0165] (1) For the centrifugal pump system, collect variable information related to the system. It mainly includes data information such as input variables, output variables and state variables, where the input variable is the rotational angular velocity ω of the centrifugal pump, the state variable is the maximum flow rate M of the pump, and the output variable is the specific energy Y of the pump. The parameters related to the above variables are: the first coefficient a of the momentum equation ac , the second coefficient a of the momentum equation R , the first coefficient of pump specific energy h ω , the second coefficient of pump specific energy h M .

[0166] (2) Construct the process equations of measurable input variables and output variables of the system by using the conservation law...

Embodiment 2

[0191]The bearing in the engine is an important part. The engine bearing operates in a complex working environment such as high temperature, high pressure, and friction. There will inevitably be problems with friction loss, cracks, and excessive wear. There will be serious consequences in time. The bearing loss rate is a measure of the wear degree of the bearing. When the loss rate is lower than a threshold, it can operate normally. When the bearing loss rate is higher than the threshold, the bearing needs to be replaced immediately. If there is a way to predict the loss rate of aircraft bearings in advance, and once the loss rate reaches a certain threshold, the alarm will be issued in advance, which can greatly reduce the incidence of accidents, which not only has important social significance, but also can effectively reduce maintenance. cost. Therefore, according to the historical data of the bearing loss rate in the system, a prediction model based on data mining is esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com