Environment-friendly automatic-exhausting battery flame-retardant label and preparation method thereof

An automatic exhaust, battery technology, applied in the field of materials, can solve the problems of difficult to fit, easy to burn battery labels, difficult to rework and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

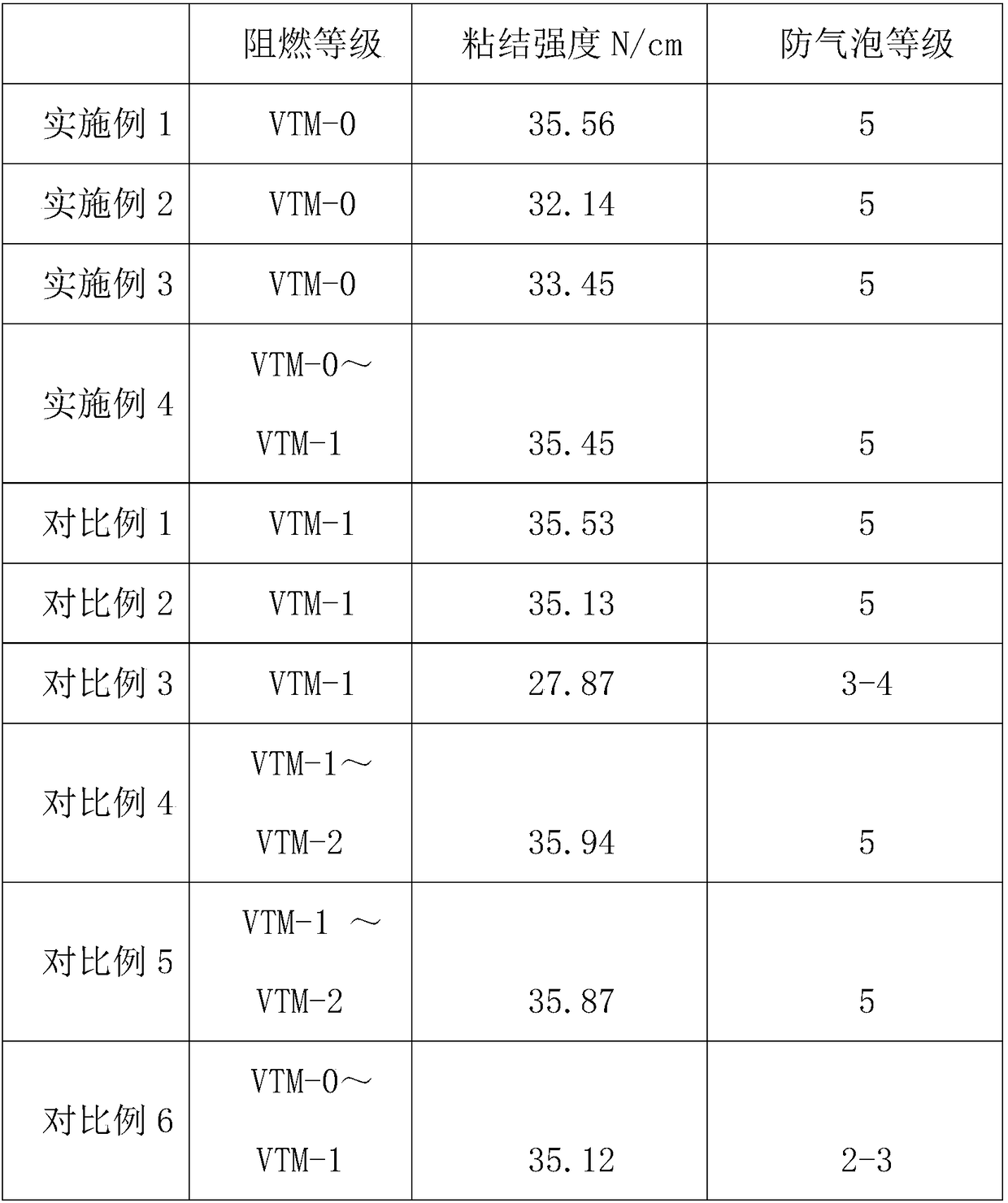

Examples

Embodiment 1

[0042] A method for preparing an environmentally friendly self-venting battery flame-retardant label is characterized in that it comprises the following steps:

[0043] (1) The mass ratio of the raw material ammonium dihydrogen phosphate, meso-tetraphenylphosphine and solvent ethyl acetate for the fireproof coating is 22.5:20:17.5, mix and stir in proportion, and use special coating equipment to uniformly coat the A 20um ordinary polyester film is coated with 7um, and the ordinary polyester film is completely wrapped by the fireproof coating; the raw material of the fireproof coating also includes 3% by mass of acrylic modified white carbon black.

[0044] (2) Do a fire-resistant printable acrylic resin treatment on the surface of the fire-resistant coating, and the coating thickness is 2.5um to form a fire-resistant printable resin layer to obtain a flame-retardant PET film;

[0045] (3) Acrylic glue: melamine: melamine phosphate: ethyl acetate is mixed according to the mass ra...

Embodiment 2

[0049] A method for preparing an environmentally friendly self-venting battery flame-retardant label is characterized in that it comprises the following steps:

[0050] (1) The mass ratio of the raw material ammonium dihydrogen phosphate, meso-tetraphenylphosphine and solvent ethyl acetate for the fireproof coating is 25:17:20, mix and stir in proportion, and use special coating equipment to uniformly coat A 20um ordinary polyester film is coated with 6um, and the ordinary polyester film is completely wrapped by the fireproof coating; the raw material of the fireproof coating also includes 5% by mass of acrylic modified white carbon black.

[0051] (2) Do a fire-resistant printable acrylic resin treatment on the surface of the fire-resistant coating, and the coating thickness is 2um to form a fire-resistant printable resin layer to obtain a flame-retardant PET film;

[0052] (3) Acrylic glue: melamine: melamine phosphate: ethyl acetate is mixed according to the mass ratio of 1...

Embodiment 3

[0056] A method for preparing an environmentally friendly self-venting battery flame-retardant label is characterized in that it comprises the following steps:

[0057] (1) The mass ratio of the raw material ammonium dihydrogen phosphate, meso-tetraphenylphosphine and solvent ethyl acetate for the fireproof coating is 20:22:15, mixed and stirred in proportion, and uniformly coated with special coating equipment 8um is coated on a 20um ordinary polyester film, and the ordinary polyester film is completely wrapped by the fireproof coating; the raw material of the fireproof coating also includes 1% by mass of acrylic modified white carbon black.

[0058] (2) Do a fire-resistant printable acrylic resin treatment on the surface of the fire-resistant coating, with a coating thickness of 3um, to form a fire-resistant printable resin layer to obtain a flame-retardant PET film;

[0059] (3) Acrylic glue: melamine: melamine phosphate: ethyl acetate is mixed according to the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com