Preparation method for flame retardant smoke-inhibiting type solid wood composite floor

A solid wood composite floor, smoke suppression technology, used in floors, covering/lining, buildings, etc., can solve the problems of poor flame retardancy and poor smoke suppression effect, and achieve improved flame retardancy, good flame retardancy and suppression. Smoke effect, effect of suppressing flammable gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

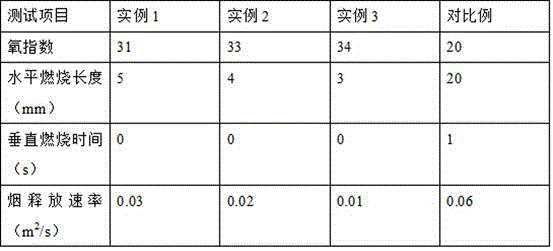

example 1

[0030]Put poplar and birch into a four-sided planer in turn to process them into planks with a size of 320mm×160mm×23mm, put them in the sun after processing, and dry them naturally for 1 hour to obtain two test materials with a moisture content of 8% to 10%. , standby, polished the birch wood sample with sandpaper for 8 minutes, then evenly coated 80mL of 50% sodium silicate solution and 3g of silicon dioxide on the poplar wood sample according to the coating amount of 200g / m2, and then applied the poplar The wood test material was pasted on the surface of the birch wood test material, and then placed in a hot press molding machine after standing for 10 minutes. Under the conditions of hot pressing temperature of 10°C and pressure of 1.2 MPa, the hot pressing treatment was performed for 10 minutes to obtain a self-made composite test material. According to the mass ratio of 1:1, attapulgite and diatomaceous earth are mixed and ground to 100 mesh, and the sieved powder is colle...

example 2

[0032] Put the poplar and birch in the four-sided planer in turn to process them into planks with a size of 320mm×160mm×23mm, put them in the sun after processing, and dry them naturally for 1.5 hours to obtain two test materials with a moisture content of 9% for later use. , polished the birch wood sample with sandpaper for 9 minutes, and then uniformly coated 90mL of 50% sodium silicate solution and 4g of silicon dioxide on the poplar wood sample according to the coating amount of 250g / m2, and then the poplar wood sample The material was pasted on the surface of the birch test material, left to stand for 15 minutes, and then put into a hot press molding machine. Under the conditions of hot pressing temperature of 11°C and pressure of 1.4 MPa, the hot pressing treatment was performed for 13 minutes to obtain a self-made composite test material. Mix and grind attapulgite and diatomite with a ratio of 1:1 to pass through 150 meshes, collect the sieved powder, and place the sieve...

example 3

[0033] Put poplar and birch into a four-sided planer in turn to process them into planks with a size of 320mm×160mm×23mm, put them in the sun after processing, and dry them naturally for 2 hours to obtain two test materials with a moisture content of 10% for later use. Sand the birch sample with sandpaper for 10 minutes, then apply 100mL sodium silicate solution with a mass fraction of 50% and 5g of silicon dioxide evenly on the poplar sample according to the coating amount of 300g / m2, and then apply the poplar sample Stick it on the surface of the birch test material, let it stand for 20 minutes, put it into a hot press molding machine, and heat it for 16 minutes under the conditions of a hot pressing temperature of 12 ° C and a pressure of 1.6 MPa to obtain a self-made composite test material. Mix and grind attapulgite and diatomaceous earth at a ratio of 1:1 to pass through 200 meshes, collect the sieved powder, and place the sieved powder in a muffle furnace at 600°C for ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com