OLED displaying substrate, manufacturing method for OLED displaying substrate, and displaying device

A display substrate and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, electrical components, etc., can solve problems such as reducing the service life of OLED devices, and achieve flexible display, enhanced ability to block external water and oxygen, The effect of meeting the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

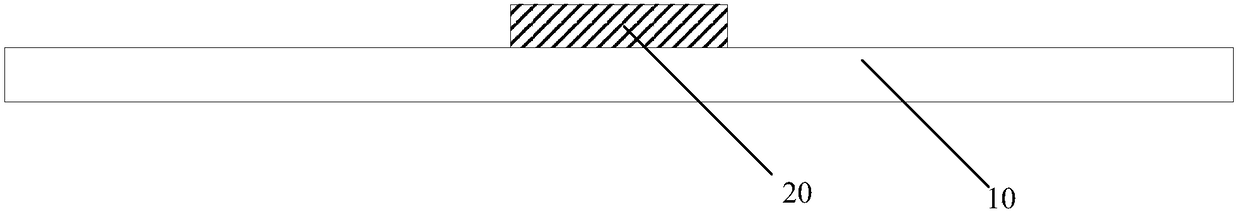

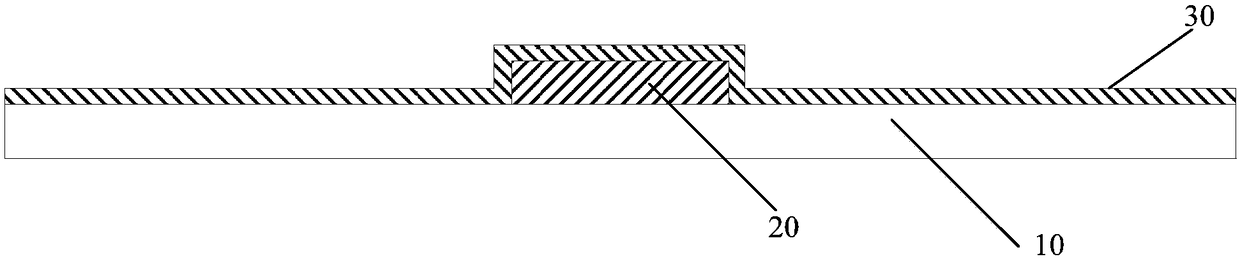

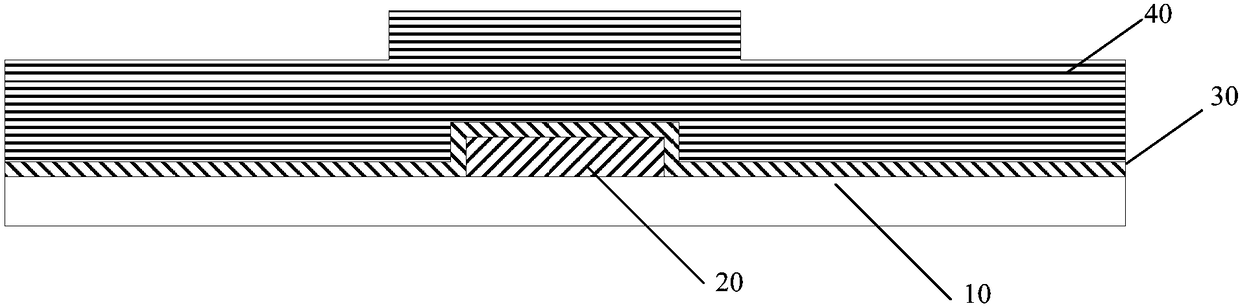

[0046] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0047] Embodiments of the present invention provide an OLED display substrate, a manufacturing method thereof, and a display device, which can enhance the ability of the OLED display substrate to block external water and oxygen, improve the service life of the OLED display substrate, and at the same time ensure sufficient light transmission of the OLED display substrate. Overrate.

[0048] An embodiment of the present invention provides an OLED display substrate, including an OLED device on a base substrate and at least one encapsulation unit covering the OLED device, each of the encapsulation units includes an inorganic layer, an organic layer, and an organic layer located on the inorganic layer. layer and the fluorine-doped diamond-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com