Plate cutting device

A cutting device and plate technology, applied in the field of plate processing, can solve the problems of increasing plastic plate processing procedures, reducing production efficiency, and low processing accuracy, and achieve the effects of improving cutting chamfering efficiency, improving chamfering accuracy, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

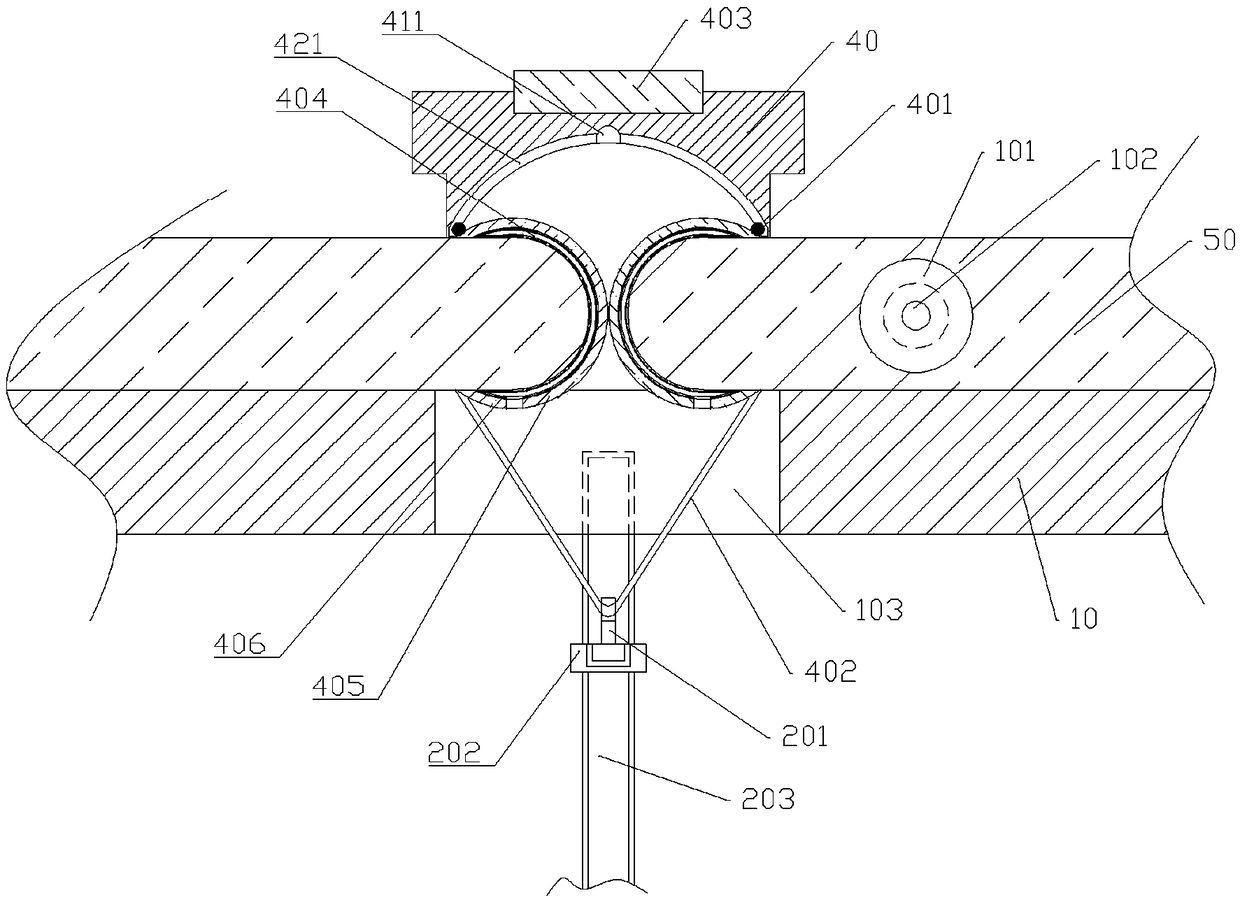

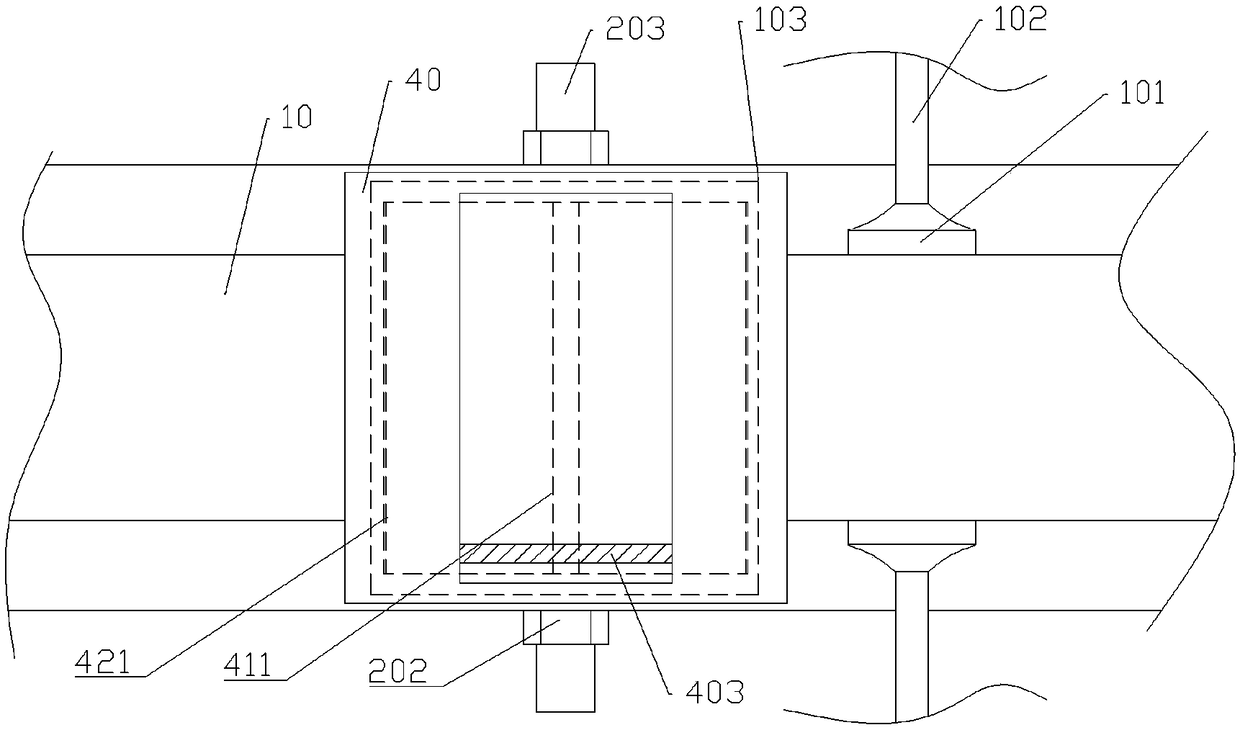

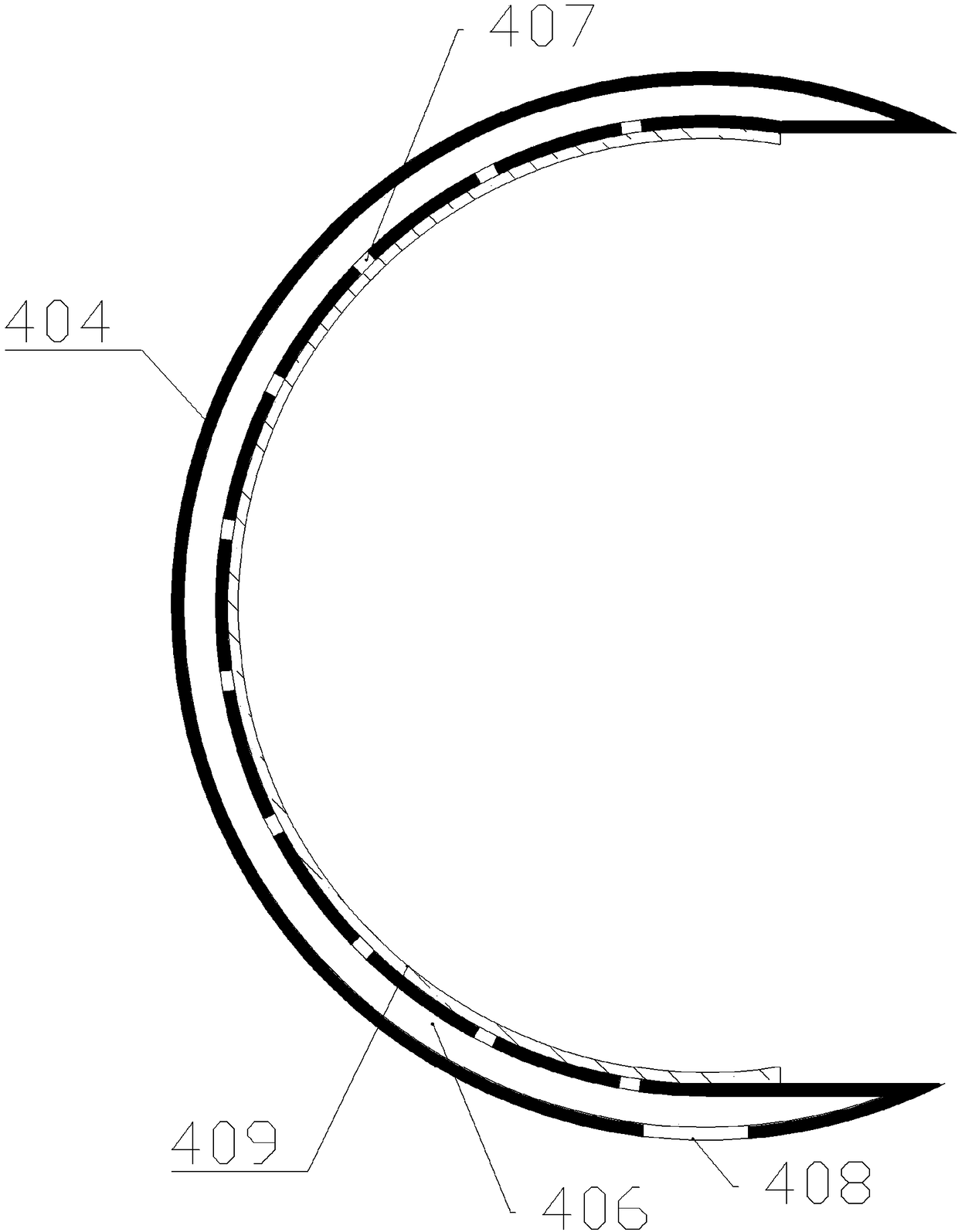

[0021] The reference signs in the accompanying drawings include: conveyor belt 10, suction cup 101, support rod 102, cutting through groove 103, hook 201, first slide rail 202, second slide rail 203, fixed block 40, slide groove 411, sliding surface 421, slider 401, pull cord 402, magnet 403, elastic cutter 404, heating wire 405, cavity 406, collection hole 407, discharge hole 408, friction bar 409, plastic plate 50.

[0022] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a plate cutting device, including a cutting mechanism, several suction cups 101, several support rods 102, a moving mechanism and a conveyor belt 10 for conveying plastic plates 50, the conveyor belt 10 is horizontally arranged, and the conveyor belt 10 is provided with several cutting through grooves 103, support rods 102 are welded horizontally on both sides of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com