Method for rapid replacement of large coal mine skip

A skip and large-scale technology, which is applied in the field of rapid replacement of large skips in coal mines, can solve the problems of long time, large area, high cost, etc., so as to reduce difficulty and workload, reduce load and area, and save civil engineering. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

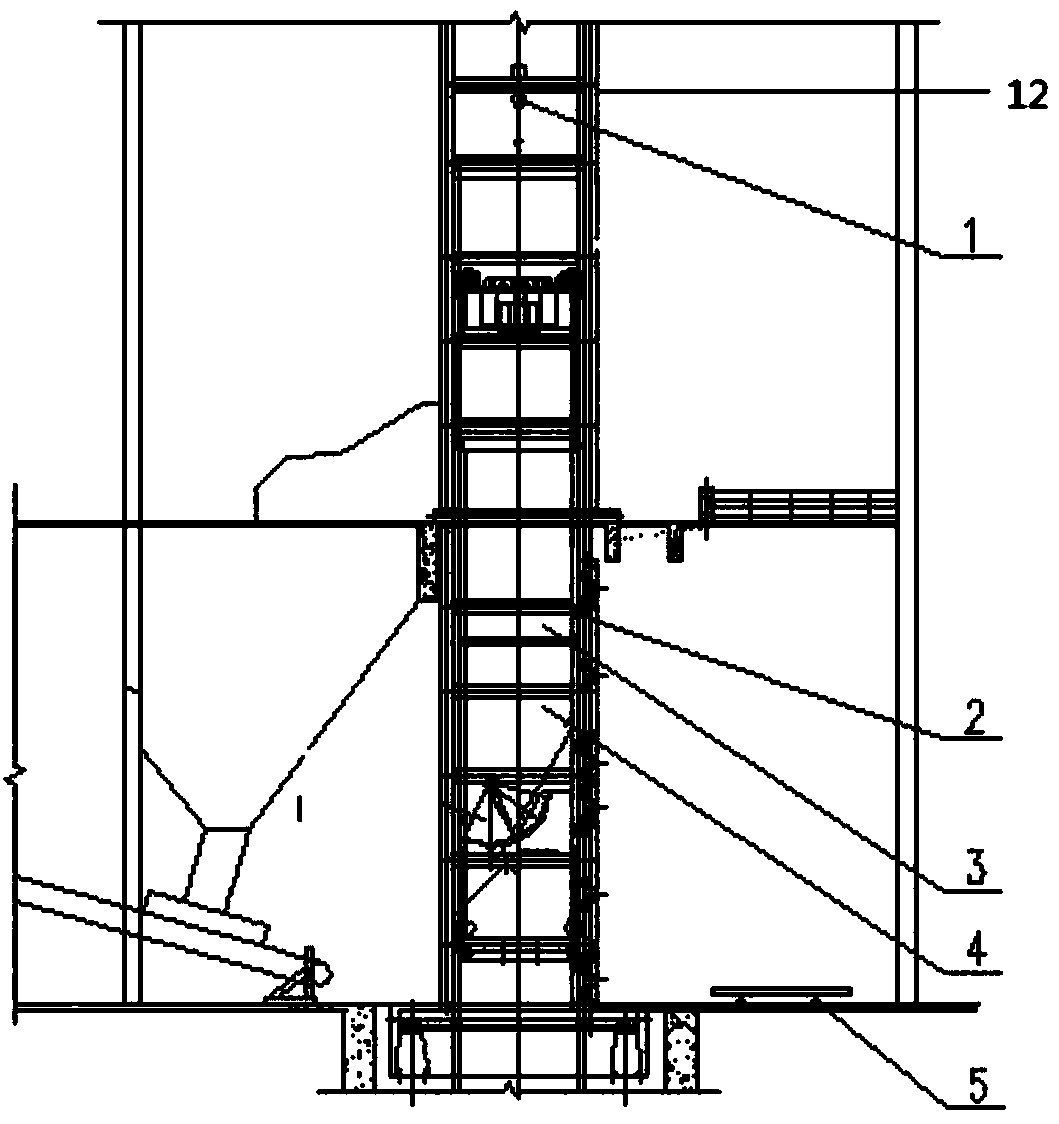

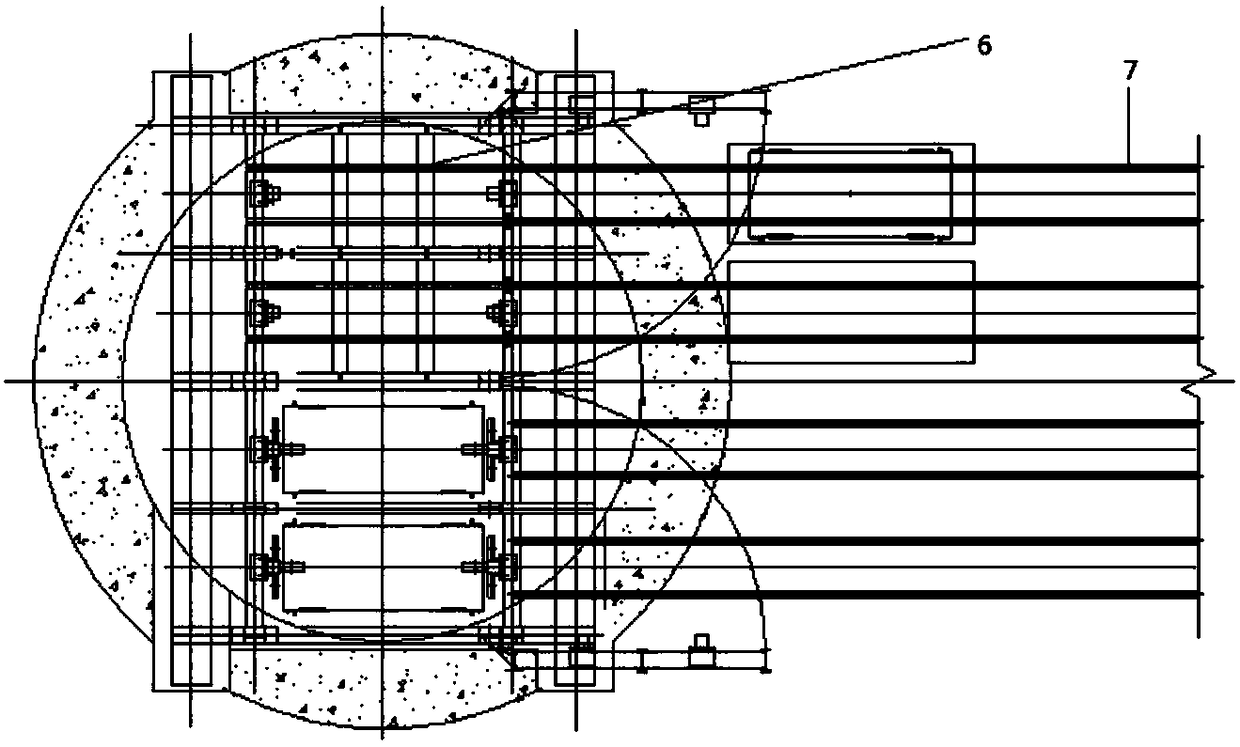

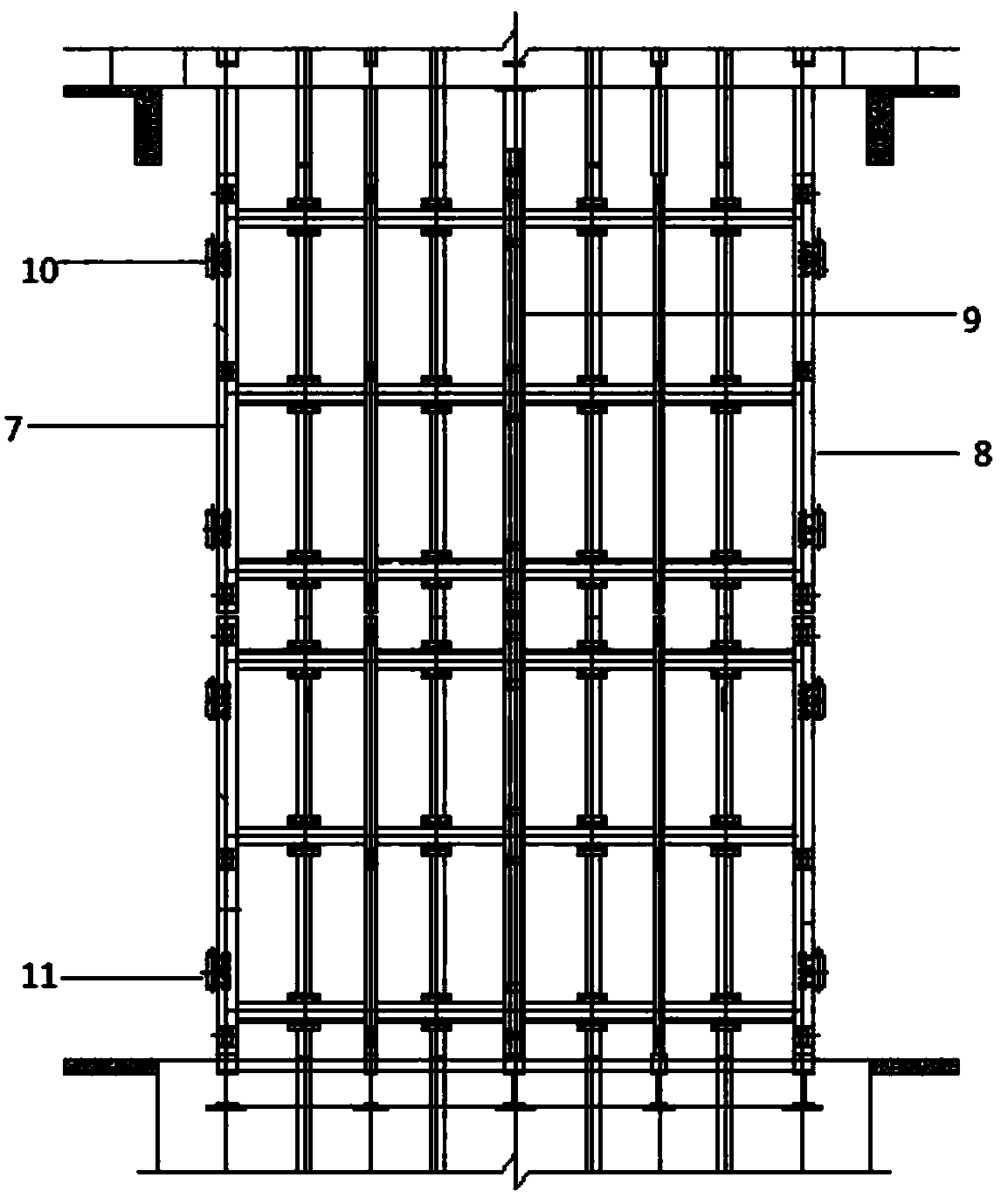

[0030] Taking the hoisting system of the main shaft of a mine as an example, it uses a skip bucket with a load of 50 tons and a self-weight of about 57 tons. It has a two-stage split structure and an overall height of more than 21 meters. The traditional design scheme is to suspend the spare skip in sections on the first floor of the main shaft tower, increasing the local floor load of the main shaft tower by more than 57 tons; the wellhead casing needs to be disassembled to a height of more than 15 meters in the direction of replacing the skip Steel structures and tanks within the range; a set of lifting and transporting devices for moving the skip from the standby position to the vicinity of the wellhead casing needs to be set in the well tower. This method increases the fixed load of the well tower, and the cost of civil construction is high; it needs to dismantle a large number of casing steel structures, which takes a long time to dismantle and install and restore, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com