A kind of preparation method of superhydrophobic polyaniline composite anticorrosion coating

A super-hydrophobic, anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high fluorine content, unfavorable industrialization, high raw material cost, and achieve low fluorine content, difficult migration, and high price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

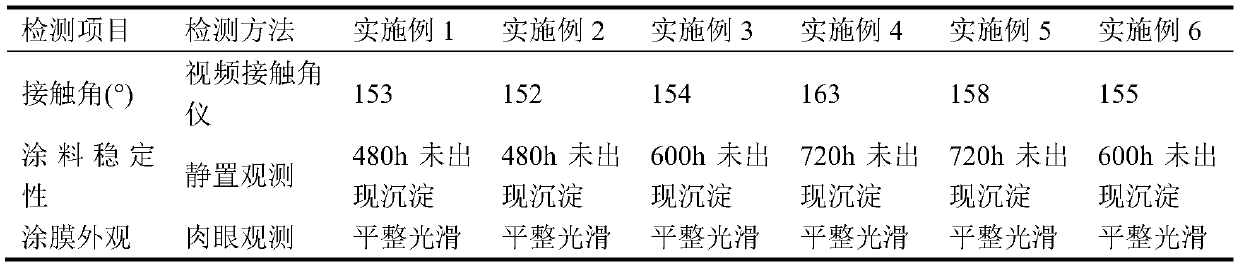

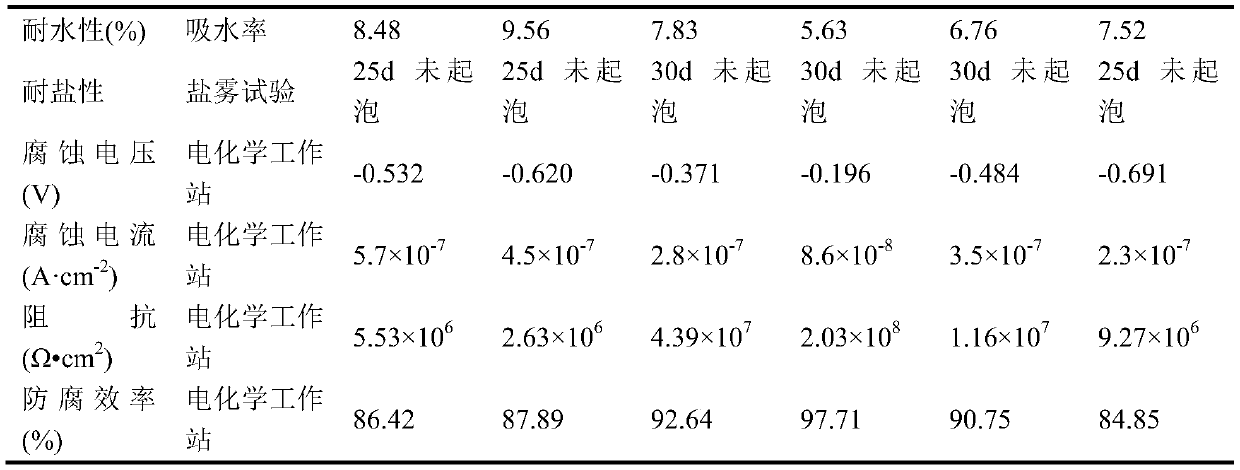

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of superhydrophobic polyaniline composite anticorrosion coating, comprises the following steps:

[0027] The preparation technology of copolymer surfactant is as follows:

[0028] a. In parts by weight, add 0.05-0.15 parts of a compound of nonionic emulsifier and 0.05-0.15 parts of anionic emulsifier, 0.8-1.1 parts of hydrophilic monomer, 0.9-1.2 parts of hydrophobic monomer into the dry reactor body, fully stirred at a reaction temperature of 60-90°C for 10-30 minutes to obtain a monomer / emulsifier mixture A;

[0029] b. Under stirring conditions, add 2 to 3 parts of initiator to the mixed solution A to initiate the polymerization reaction between the monomers, and the reaction time is 15 to 30 minutes to prepare the pre-emulsion B;

[0030] c. Add 7.2-9.9 parts of hydrophilic monomer, 8.1-10.8 parts of hydrophobic monomer and 4-6 parts of initiator dropwise into pre-emulsion B at the same time. The reaction temperat...

Embodiment 1

[0038] Wherein, the preparation technology of copolymer surfactant is as follows:

[0039]1) 0.1 part of nonylphenol polyoxyethylene ether (TX-10), 0.1 part of sodium lauryl sulfate, 0.8 part of hydrophilic monomer 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 1.2 Parts of hydrophobic monomer hexafluorobutyl acrylate were thoroughly mixed, the reaction temperature was 80°C, and the reaction was stirred for 10 minutes;

[0040] 2) Then add 2.5 parts of ammonium persulfate (APS), polymerize for 15 minutes, and finally add the remaining 7.2 parts of hydrophilic monomer 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 10.8 parts of hydrophobic monomer Fluorobutyl ester and 5 parts of ammonium persulfate (APS) initiator are added dropwise at the same time, the monomer dropping time is controlled at 3.5h, the end time of the initiator dropping is 0.5h later than the monomer dropping end time, and then the stirring reaction is continued for 1h , After treatment, a fluorine-cont...

Embodiment 2

[0046] Wherein, the preparation technology of copolymer surfactant is as follows:

[0047] 1) Add 0.05 parts of octylphenol polyoxyethylene ether (OP-10), 0.05 parts of sodium dodecylbenzenesulfonate, and 0.85 parts of hydrophilic monomer 2-acrylamide-2-methylpropanesulfonic acid (AMPS) , 1.15 parts of hydrophobic monomer hexafluorobutyl acrylate were fully mixed, the reaction temperature was 70°C, and the reaction was stirred for 10 minutes;

[0048] 2) Then add 2 parts of ammonium persulfate (APS), polymerize for 15 minutes, and finally add the remaining 7.65 parts of hydrophilic monomer 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 10.35 parts of hydrophobic monomer Fluorobutyl ester and 4 parts of ammonium persulfate (APS) initiators are added dropwise at the same time, the monomer dropping time is controlled at 3h, the initiator dropping end time is 0.5h later than the monomer dropping end time, and then the stirring reaction is continued for 1h, After treatment, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com