Elastic fabric and production process thereof

A technology of elastic fabric and production process, which is applied in the field of textiles, can solve the problems that elastic fabric is easy to deform, etc., and achieve the effect of improving bulkiness and elasticity, and the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

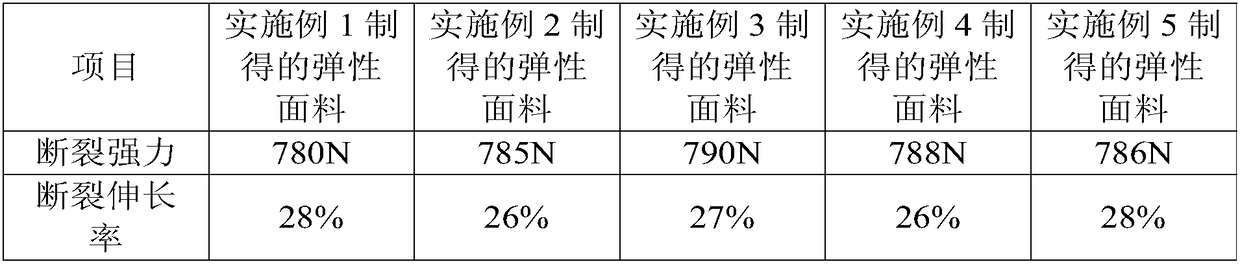

Examples

Embodiment 1

[0027] A kind of elastic fabric, the grammage of elastic fabric is 100g / m 2 The elastic fabric adopts plain weave, the warp tightness is 35%, and the weft tightness is 32%; the elastic fabric adopts spandex fiber / nylon fiber two-component composite fiber; The mass ratio of nylon fiber is 1:0.1; the twist of spandex fiber / nylon fiber two-component composite fiber is: 680T / m; among them, in spandex fiber / nylon fiber two-component composite fiber: the single yarn twist of spandex fiber is: 850T / m, the single yarn twist of nylon fiber is: 980T / m; The preparation method of described spandex fiber / nylon fiber two-component composite fiber comprises the following steps:

[0028] Step i, blending spandex fiber, nylon fiber, and water-soluble polyvinyl alcohol fiber into fibers according to a mass ratio of 1:0.1:0.2 to obtain spandex fiber / nylon fiber / water-soluble polyvinyl alcohol blended fiber;

[0029] Step ii, passing the blended fiber of spandex fiber / nylon fiber / water-soluble p...

Embodiment 2

[0035] A kind of elastic fabric, the grammage of elastic fabric is 120g / m 2 The elastic fabric adopts plain weave, the warp tightness is 40%, and the weft tightness is 38%; the elastic fabric adopts spandex fiber / nylon fiber two-component composite fiber; The mass ratio of nylon fiber is 1:0.3; the twist of spandex fiber / nylon fiber two-component composite fiber is: 750T / m; among them, in spandex fiber / nylon fiber two-component composite fiber: the single yarn twist of spandex fiber is: 950T / m, the single yarn twist of nylon fiber is: 1050T / m; The preparation method of described spandex fiber / nylon fiber two-component composite fiber comprises the following steps:

[0036] Step i, blending spandex fiber, nylon fiber, and water-soluble polyvinyl alcohol fiber into fibers according to a mass ratio of 1:0.3:0.4 to obtain spandex fiber / nylon fiber / water-soluble polyvinyl alcohol blended fiber;

[0037] Step ii, passing the blended fiber of spandex fiber / nylon fiber / water-soluble ...

Embodiment 3

[0043] An elastic fabric, the grammage of the elastic fabric is 110g / m 2 The elastic fabric adopts plain weave, the warp tightness is 37%, and the weft tightness is 35%; the elastic fabric adopts spandex fiber / nylon fiber two-component composite fiber; The mass ratio of nylon fiber is 1:0.2; the twist of spandex fiber / nylon fiber two-component composite fiber is: 710T / m; among them, in the spandex fiber / nylon fiber two-component composite fiber: the single yarn twist of spandex fiber is: 900T / m, the single yarn twist of nylon fiber is: 1000T / m; The preparation method of described spandex fiber / nylon fiber two-component composite fiber comprises the following steps:

[0044] Step i, blending spandex fiber, nylon fiber, and water-soluble polyvinyl alcohol fiber into fibers according to a mass ratio of 1:0.2:0.3 to obtain spandex fiber / nylon fiber / water-soluble polyvinyl alcohol blended fiber;

[0045] In step ii, the spandex fiber / nylon fiber / water-soluble polyvinyl alcohol fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com