Furrowing and sowing machine and sowing method thereof

A technology of a seeder and a seeding mechanism, which is applied to the planting method, the machinery of interval-type quantitative seeding, and the excavation/covering of trenches, etc. problems, to achieve the effect of reducing work intensity, liberating manpower, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

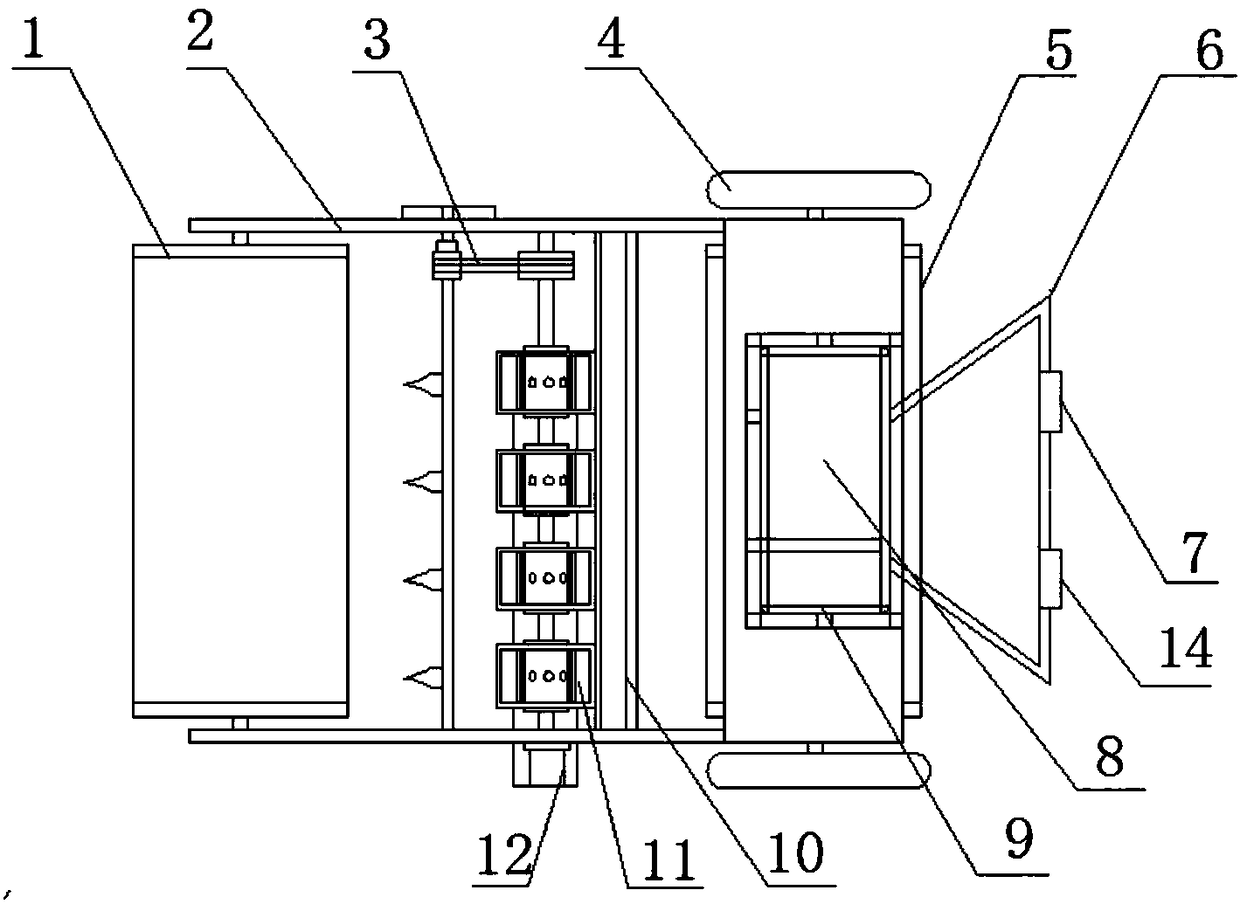

[0032] Such as figure 1 As shown, a ditching seeder includes a first leveling wheel 1, a frame 2, a ditching mechanism 3, a hub motor 4, a second leveling wheel 5, a support armrest 6, a scraper 10, and a seeding mechanism 11 , stepping motor 12 and control module. The first leveling soil wheel 1 and the second leveling soil wheel 5 are respectively supported on the two ends of the frame 2 bottom. The fixed shafts of two wheel hub motors 4 coaxially arranged are fixed respectively with the both sides of the frame tail end, and are all coaxially arranged with the second leveling wheel 5 . The outer edge of the hub motor 4 is covered with tires. The support armrest 6 is fixed on the frame 2 by bolts. Support armrest 6 is positioned at the frame tail end.

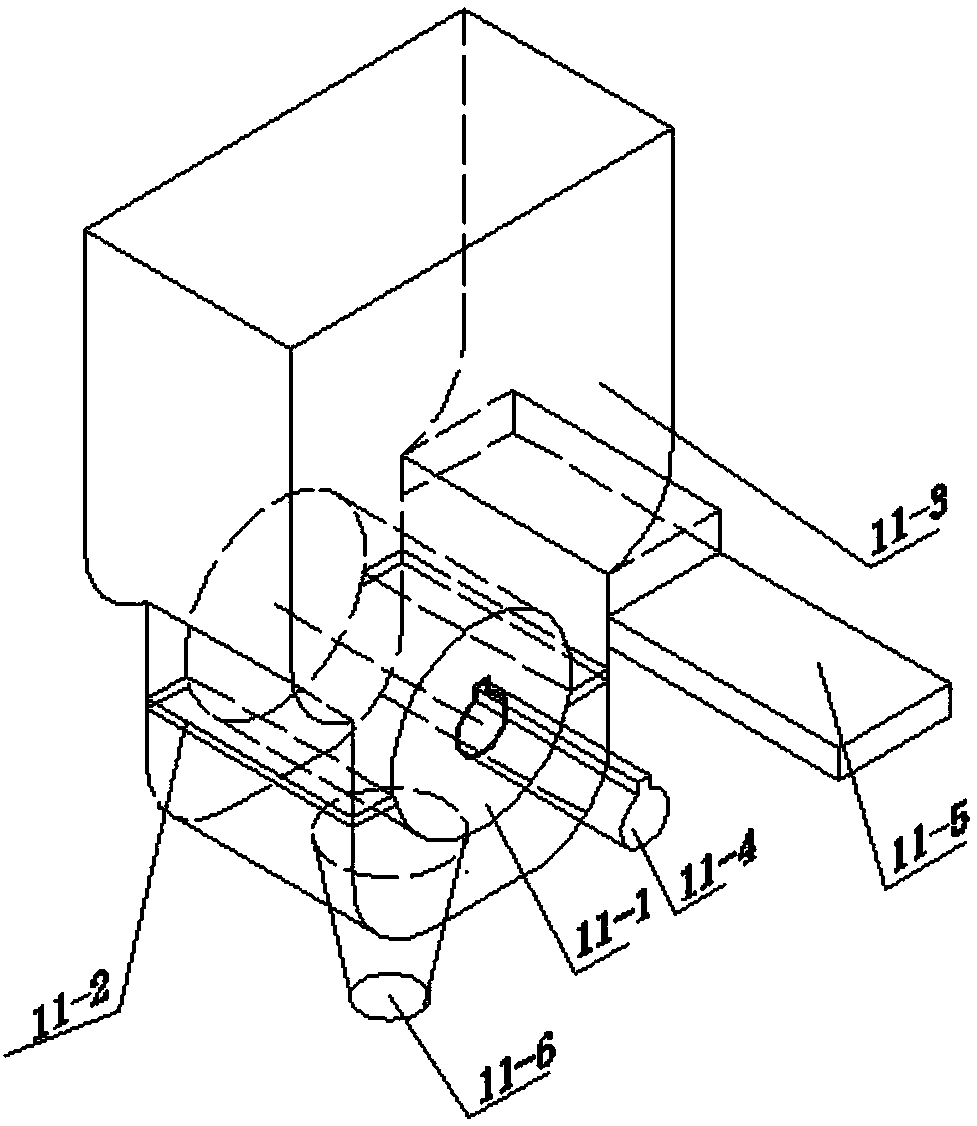

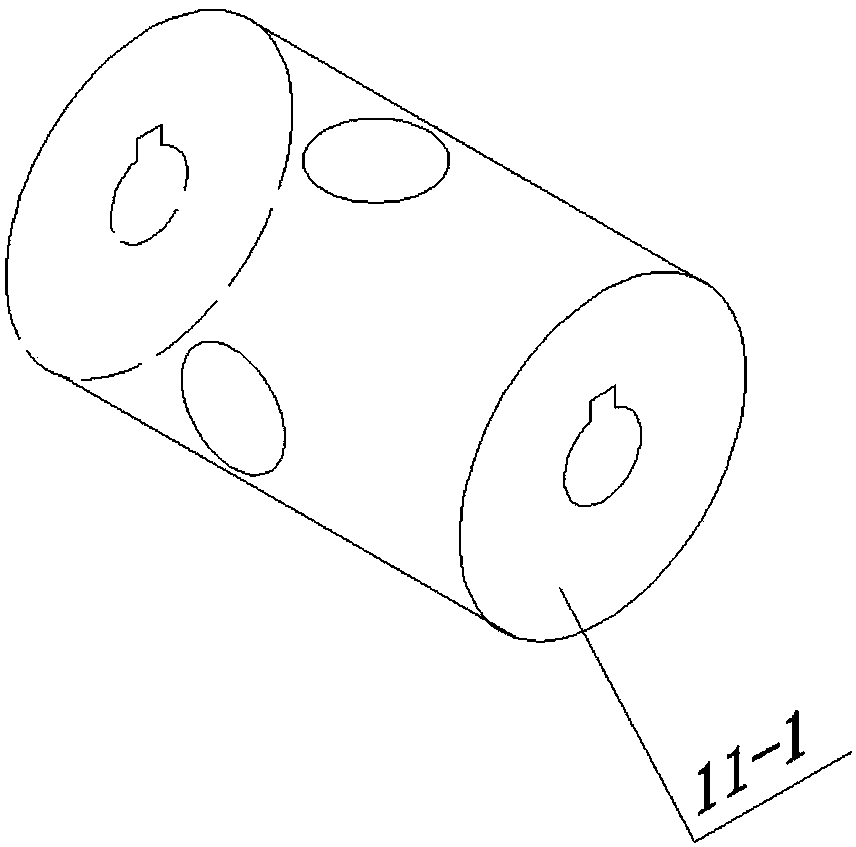

[0033] Such as figure 1 , 2 As shown in and 3, the sowing mechanism 11 includes a roller 11-4, a support plate 11-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com