Separate logging robot

A robot and separate technology, applied in the field of robots, can solve the problems of no ground lifting, low safety, high risk, etc., and achieve the effect of improving work efficiency, improving logging efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

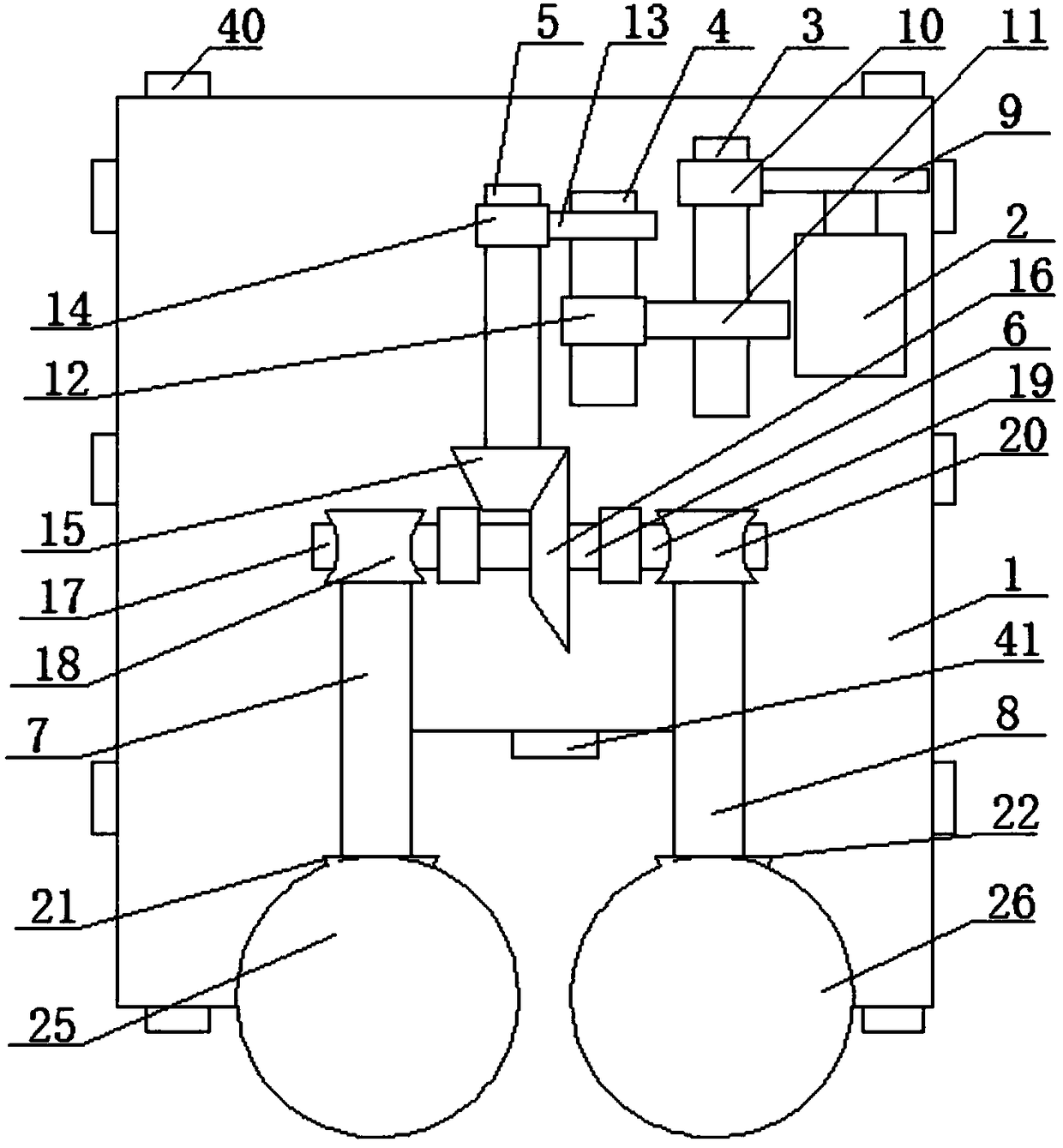

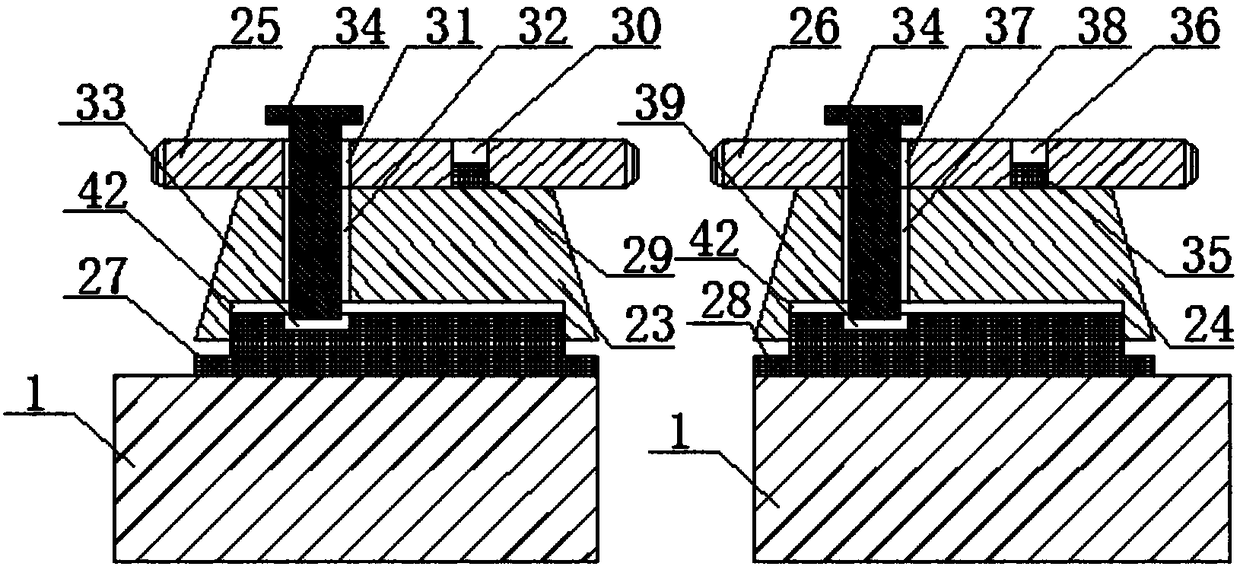

[0037] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

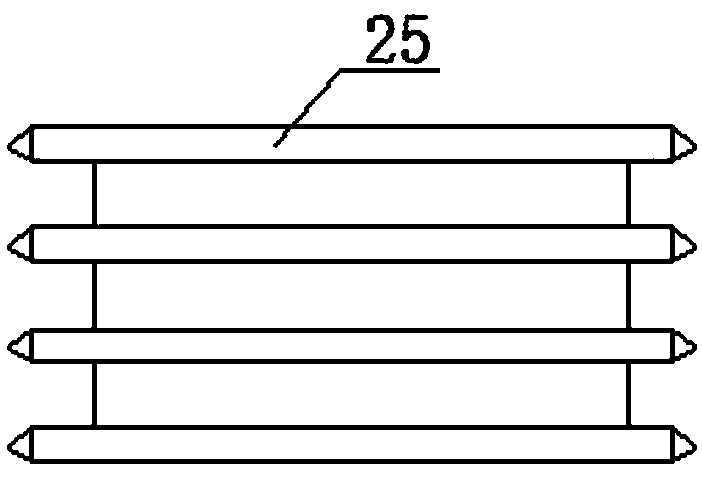

[0038] Such as Figure 1 to Figure 4As shown, a detached logging robot includes robot body 1, servo motor 2, axis I3, axis II4, axis III5, axis IV6, axis V7, axis VI8, large gear I9, pinion I10, large gear II11, small Gear II12, large gear III13, pinion gear III14, bevel gear I15, bevel gear II16, worm I17, turbine I18, worm II19, turbine II20, bevel gear III21, bevel gear IV22, bevel gear V23, bevel gear VI24, saw blade I25 , saw blade II26, plane bearing I27 and plane bearing II28; the bottom end of the servo motor 2 is fixedly connected to the top end of the robot body 1, the shaft I3, shaft II4, shaft III5, shaft IV6, shaft V7, shaft VI8 is rotationally connected with the top of the robot body 1 through bearings respectively; the large gear I9 is connected with the shaft of the servo motor 2 through a key, the small gear I10 and the large ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com