Waterproof sunscreen cosmetic and preparation method

A technology of cosmetics and water resistance, which is applied in the field of sunscreen cosmetics and its preparation. It can solve the problems of difficult to match cosmetics, easy oxidation and deterioration, poor light stability, etc., and achieve good protection effect, improve sunscreen effect, and good sunscreen effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

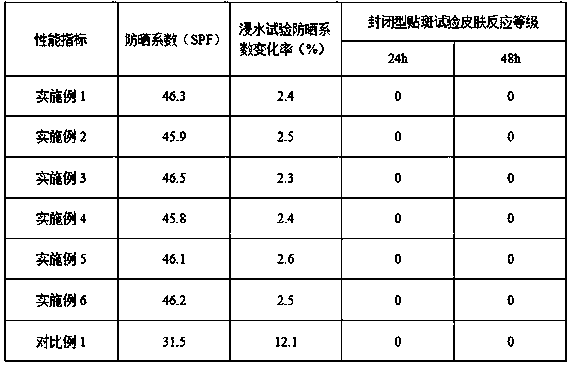

Examples

Embodiment 1

[0053] (1) Put nanoporous zinc oxide in the dispersion of titanate coupling agent, stir for 36 minutes, filter and dry to obtain modified nanoporous zinc oxide, and then mix with isooctyl methoxycinnamate, 3- (4-Methylbenzylidene) camphor is added to the circulating pneumatic mixer together, so that isooctyl methoxycinnamate and 3-(4-methylbenzylidene) camphor are loaded on the modified nanoporous oxide Composite sunscreen agent A is prepared on the surface and voids of zinc;

[0054] (2) Put nanoporous titanium dioxide in the dispersion of silane coupling agent, ultrasonically treat it for 110 minutes, filter and dry to obtain modified nanoporous titanium dioxide, and then mix with 4-tert-butyl-4-methoxydibenzoyl Add methane and diethylhexylbutyramide triazone together into a circulating pneumatic mixer to load 4-tert-butyl-4-methoxydibenzoylmethane on the surface and voids of the modified nanoporous titanium dioxide , to prepare composite sunscreen B;

[0055] (3) Mix comp...

Embodiment 2

[0086] (1) Put nanoporous zinc oxide in the dispersion of titanate coupling agent, stir for 30 minutes, filter and dry to obtain modified nanoporous zinc oxide, and then mix with isooctyl methoxycinnamate, 3- (4-Methylbenzylidene) camphor is added to the circulating pneumatic mixer together, so that isooctyl methoxycinnamate and 3-(4-methylbenzylidene) camphor are loaded on the modified nanoporous oxide Composite sunscreen agent A is prepared on the surface and voids of zinc;

[0087] (2) Put nanoporous titanium dioxide in the dispersion of silane coupling agent, ultrasonically treat it for 100 minutes, filter and dry to obtain modified nanoporous titanium dioxide, and then mix with 4-tert-butyl-4-methoxydibenzoyl Add methane and diethylhexylbutyramide triazone together into a circulating pneumatic mixer to load 4-tert-butyl-4-methoxydibenzoylmethane on the surface and voids of the modified nanoporous titanium dioxide , to prepare composite sunscreen B;

[0088] (3) Mix comp...

Embodiment 3

[0115] (1) Put nanoporous zinc oxide in the dispersion of titanate coupling agent, stir for 40 minutes, filter and dry to obtain modified nanoporous zinc oxide, and then mix with isooctyl methoxycinnamate, 3- (4-Methylbenzylidene) camphor is added to the circulating pneumatic mixer together, so that isooctyl methoxycinnamate and 3-(4-methylbenzylidene) camphor are loaded on the modified nanoporous oxide Composite sunscreen agent A is prepared on the surface and voids of zinc;

[0116] (2) Place nanoporous titanium dioxide in the dispersion of silane coupling agent, ultrasonically treat it for 120 minutes, filter and dry to obtain modified nanoporous titanium dioxide, and then mix with 4-tert-butyl-4-methoxydibenzoyl Add methane and diethylhexylbutyramide triazone together into a circulating pneumatic mixer to load 4-tert-butyl-4-methoxydibenzoylmethane on the surface and voids of the modified nanoporous titanium dioxide , to prepare composite sunscreen B;

[0117] (3) Mix co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com