Gas purifier

A gas purifier and gas technology, applied in chemical instruments and methods, using liquid separation agents, chemical/physical processes, etc., can solve the problem that the total amount of fine particles in the gas is not large, the cost of exhaust gas purification is high, and the purification of exhaust gas will not be considered. Smoke and other problems, to avoid economic losses, significant purification effect, and save medical expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

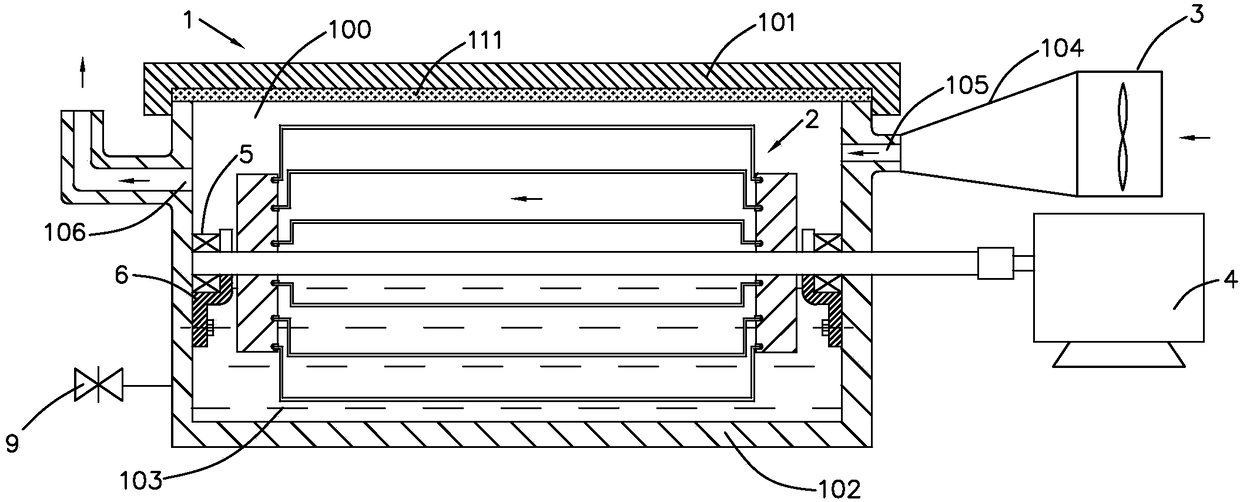

[0058] Embodiment 1, referring to Fig. 1, the arrow in the figure is the gas flow direction, a kind of gas purifier, mainly comprises purifying main body 1, purifying liquid 103, motor 4, and described purifying main body 1 is provided with air inlet 105 and air outlet 106 , is characterized in that: it also includes a bearing system and a stirrer 2 for mixing gas and purification liquid, the purification body 1 includes a purification body part 101 and a purification body part 102, the purification body part 101 and purification The second part 102 of the main body forms a purification chamber 100, the purification liquid 103 is placed in the purification chamber 100, the bearing system is connected with the turbulence 2 to fix the turbulence 2 on the purification main body 1, and the turbulence 2 is connected to the motor Driven by the high-speed rotation of 4, the gas to be purified is mixed with the purification liquid 103 in the purification chamber 100.

[0059] Such as ...

Embodiment 2

[0076] Embodiment 2. This embodiment is similar to Embodiment 1. The repeated parts will not be repeated, and the differences will be described. The main differences in this embodiment are:

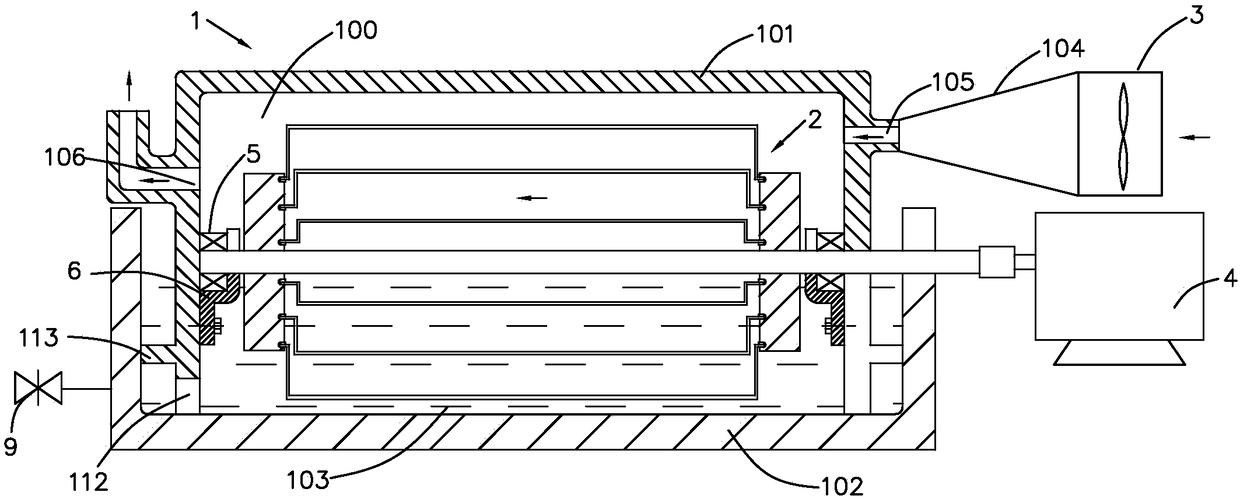

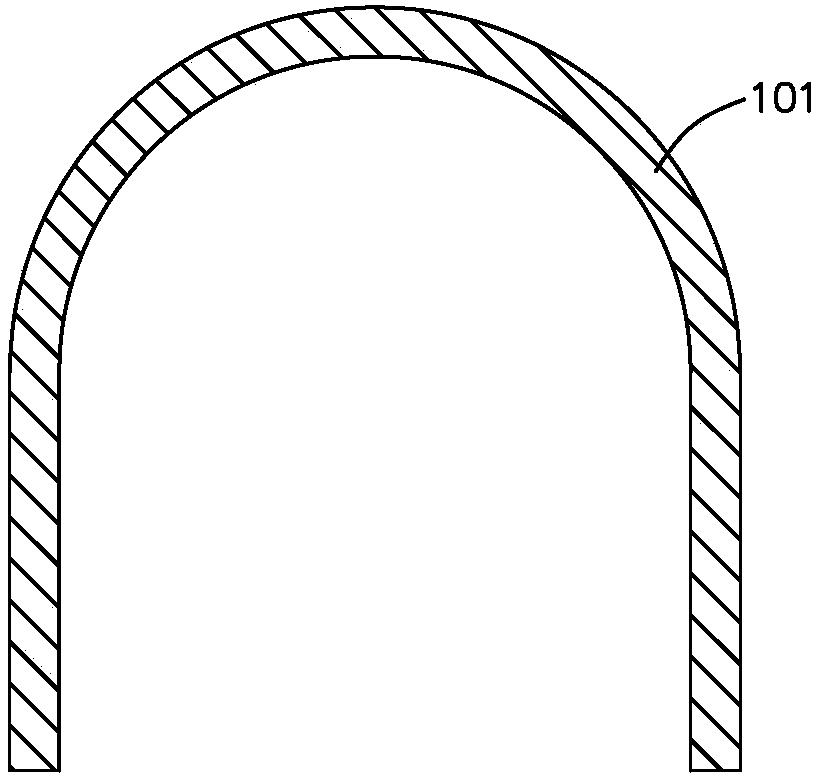

[0077] Such as figure 2 As shown, the purification body part 101 in this embodiment is open at the bottom, and the purification body part 101 is a box type, or the cross section of the purification body part 101 is an inverted "U" shape ( image 3 shown), the upper part 102 of the purification main body is open, the second part 102 of the purification main body is a box type, the first part of the purification main body 101 is placed at the bottom of the second part 102 of the purification main body, and the first part of the purification main body 101 is open The mouth end is provided with a communication groove 112, and the communication groove 112 communicates with the purification liquid 103 in the purification body part 101 and the purification body part 102, and the purification bo...

Embodiment 3

[0078] Embodiment 3. This embodiment is similar to Embodiment 1. The repeated parts will not be repeated, and the differences will be explained. The main differences of this embodiment are:

[0079] Such as Figure 4 As shown, the cross-section of the purification body part 101 in this embodiment is rectangular, or circular, or a closed inverted "U" shape ( Figure 5 shown), the two ends of the purification body part 101 are open, the purification body part 102 is matched with the two open end faces of the purification body part 101, and the two open end faces of the purification body part 101 are respectively fixed with one Purify the second part 102 of the main body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com