Automatic positioning-detecting system based on tube-boring perforating lathe

A technology for positioning detection and drilling pipe, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc. problems, to achieve the effect of improving work efficiency, shortening the required time, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

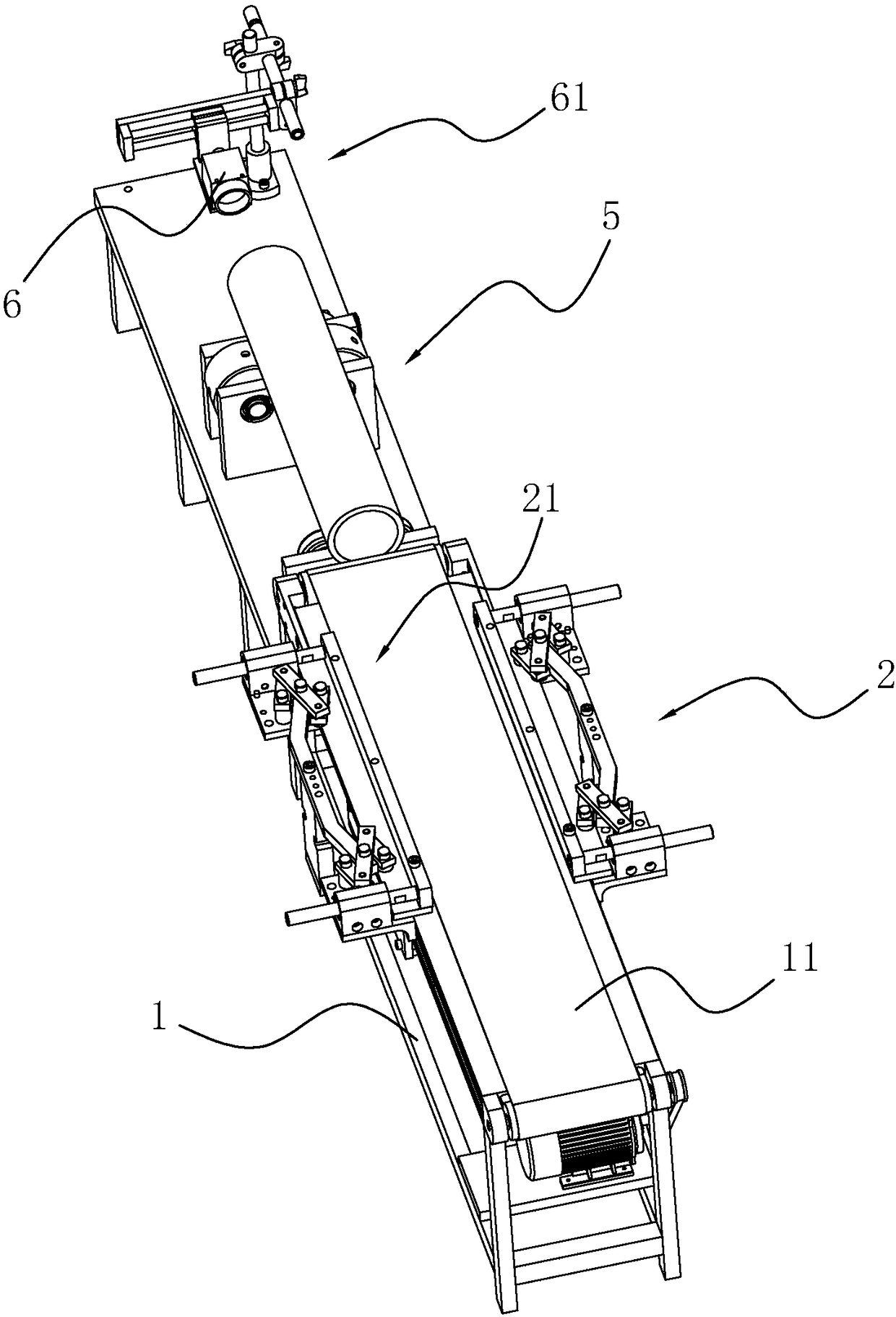

[0040] An automatic positioning detection system based on a drill pipe drilling lathe, such as figure 1As shown, it includes a frame 1, which is provided with a pulley 11 for conveying drill pipes, and a positioning mechanism 2 is arranged at the end of the pulley 11, that is, the semi-finished drill pipes are conveyed through the pulley 11 and centered by the positioning mechanism 2 Finish punching after fixing.

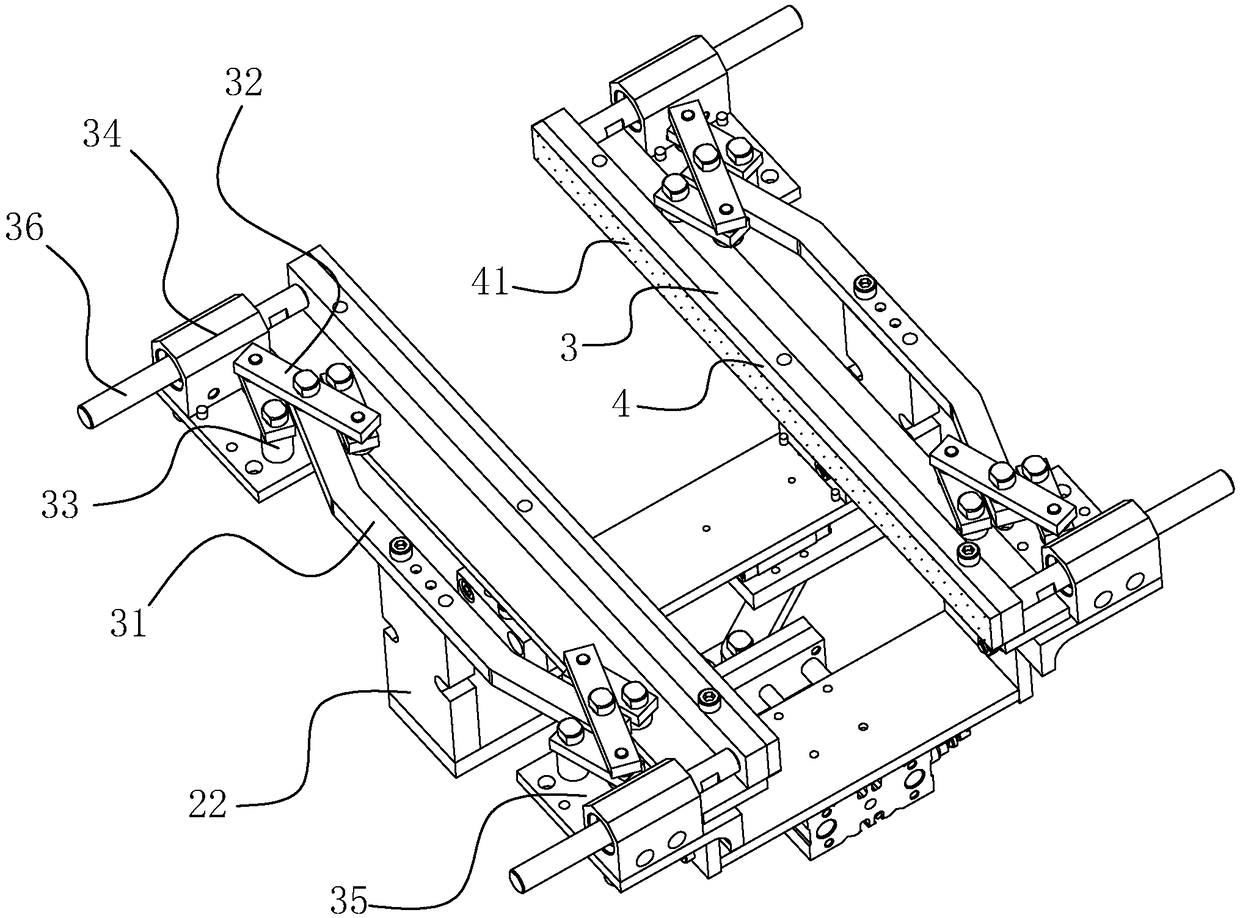

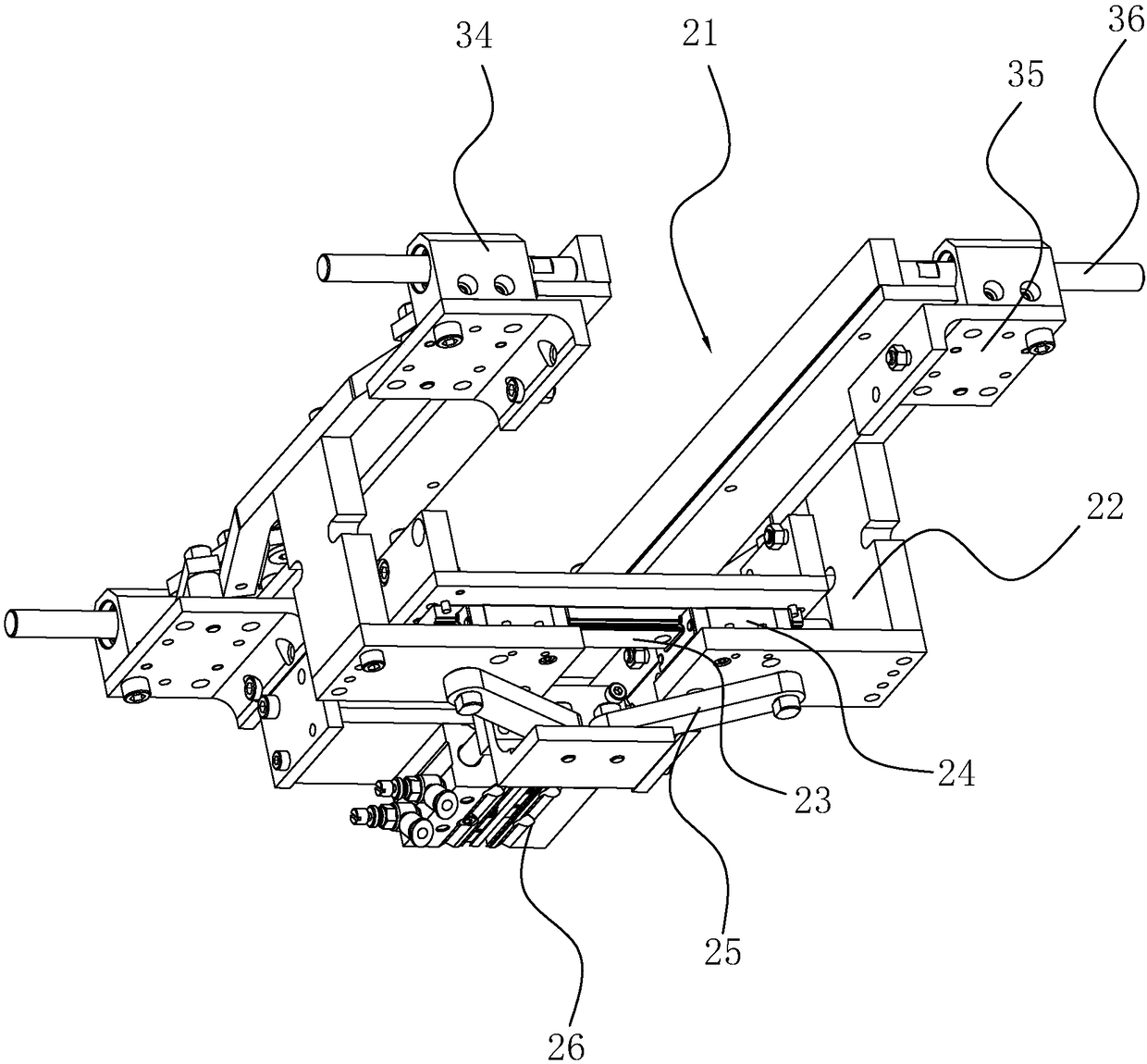

[0041] In order to prevent the deviation of the drill pipe to be processed and affect the accuracy of drilling, such as figure 1 As shown, the positioning mechanism 2 includes a pair of side jacks 21 arranged symmetrically and positioned at the end of the pulley 11. The length of the side jacks 21 is consistent with the length of the drill pipe, and the two side jacks 21 are connected to a driving transmission mechanism, so that When the pulley 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com