Physical dismounting and recycling device for waste power lithium battery set

A lithium battery pack and recycling device technology, applied in battery recycling, waste collector recycling, secondary batteries, etc., to achieve the effect of not polluting the environment, simple and reliable operation, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

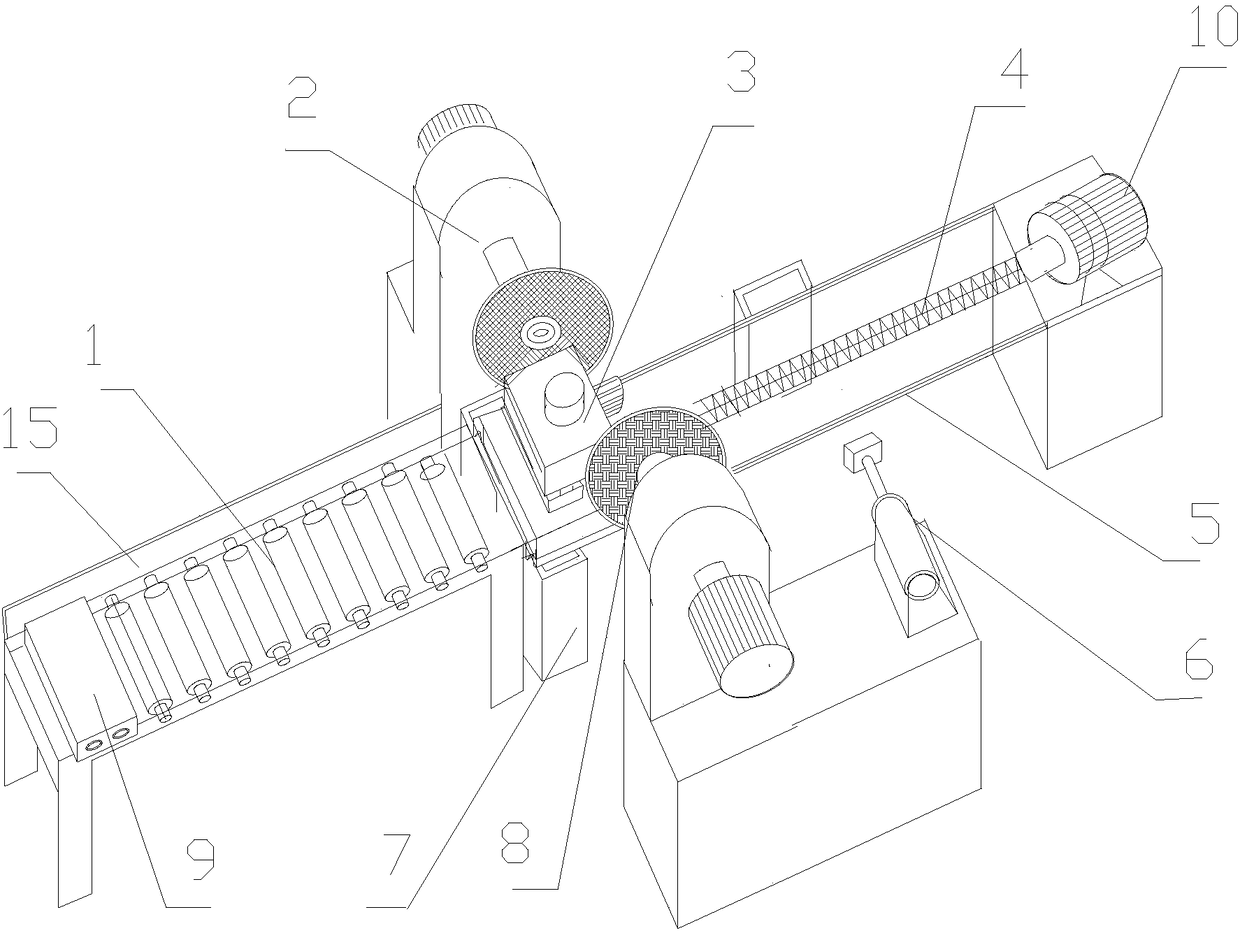

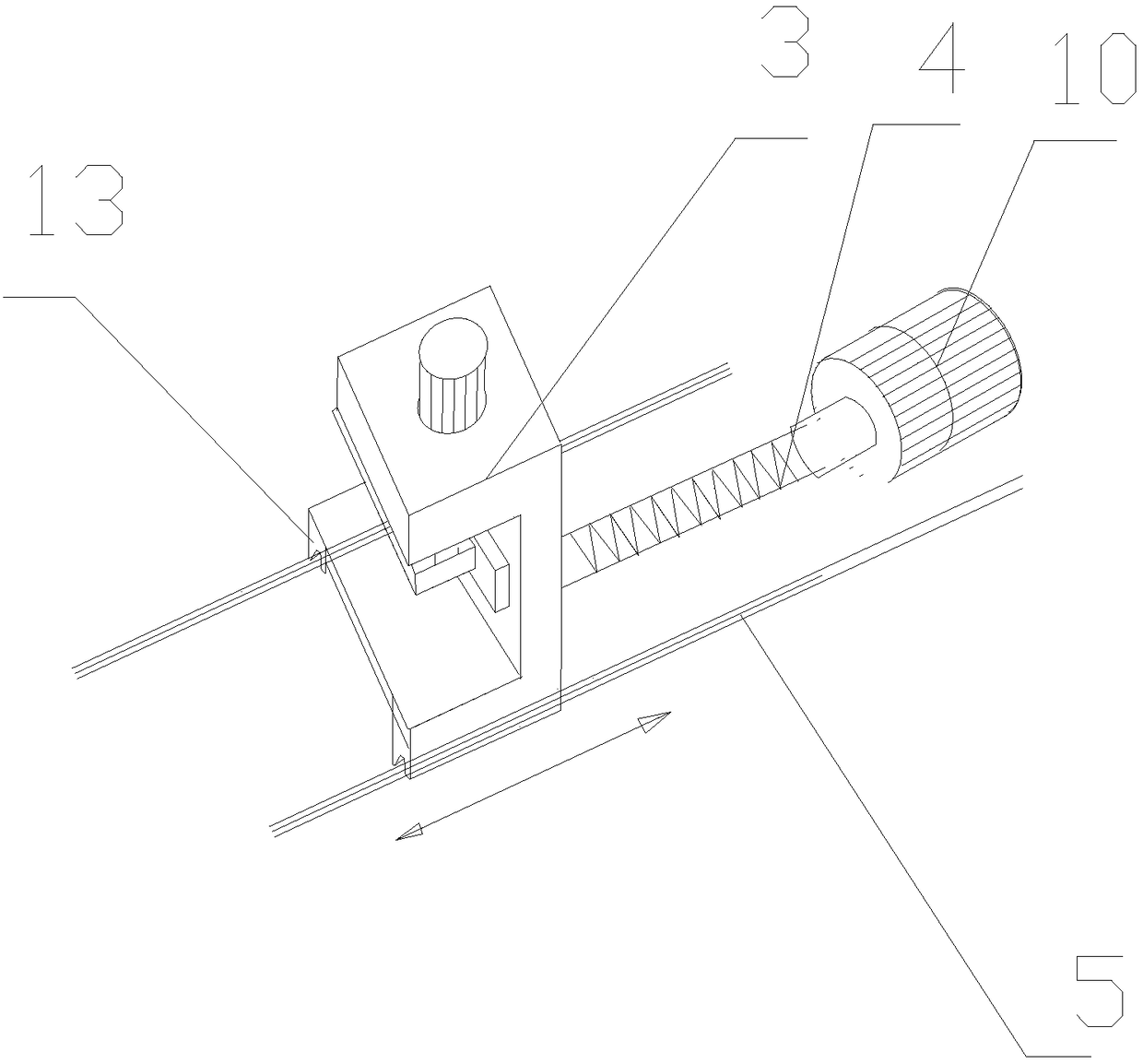

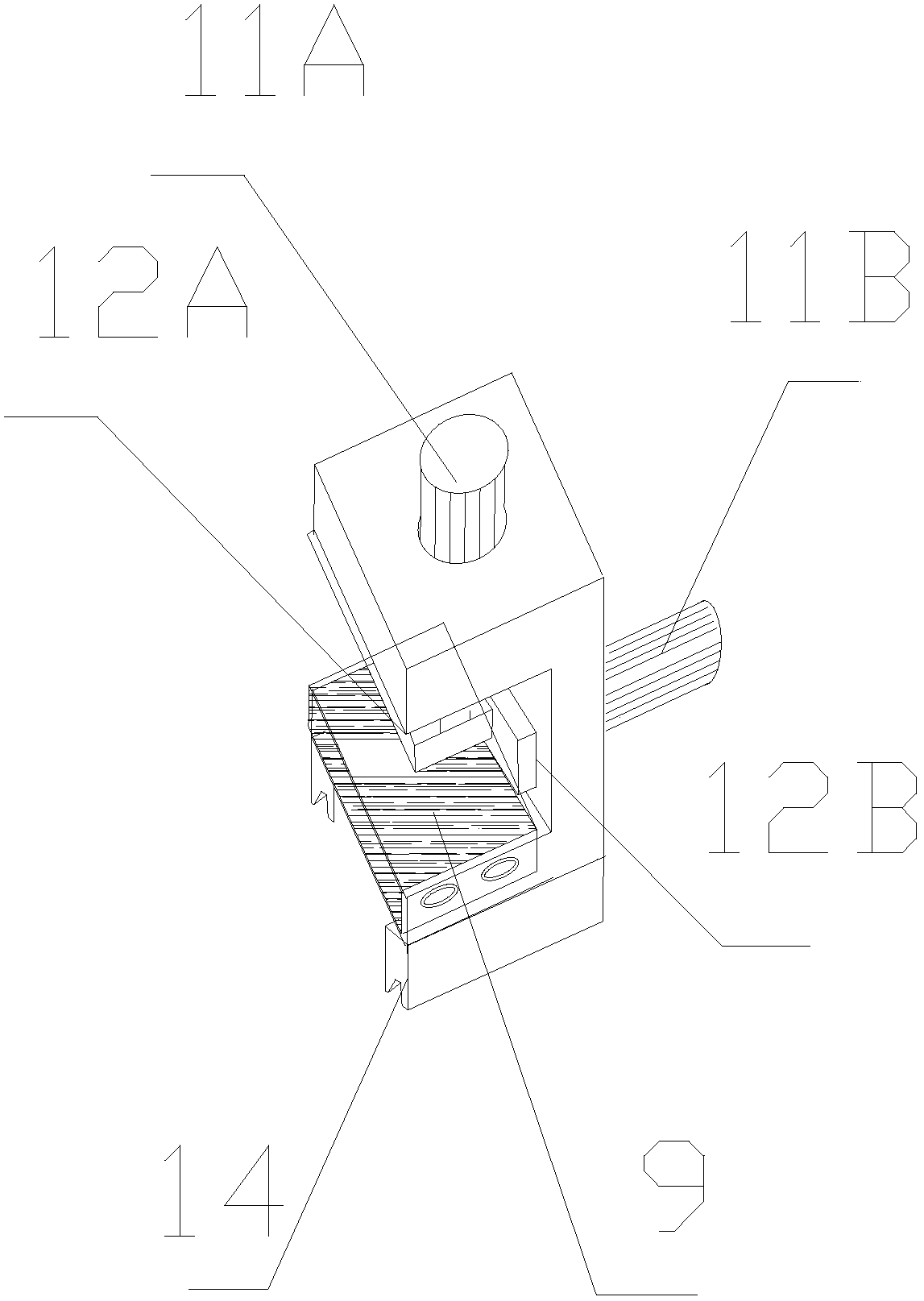

[0021] Such as Figure 1-4 As shown, the present invention provides a physical dismantling and recycling device for waste power lithium battery packs, including a roller conveying device 1, a grinding wheel cutting power assembly 2, an automatic clamping seat 3, a screw transmission pair 4, a guide rail 5, and a side pusher discharge Device 6, waste bin 7; the roller conveying device 1 is a self-sliding roller group in which a plurality of rollers are uniformly inlaid and installed on a slideway, and waste batteries 9 are placed on the top, and a material positioning baffle 15 is arranged on the left side, and the bottom of the waste battery material The end rests on the positioning baffle, and the parallel displacement ensures uniform and consistent cutting lines; the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com