High-temprature-resisting, mildew-proof and antibacterial type nano waterborne baking finish and preparation method thereof

A mildew-proof, antibacterial and high-temperature-resistant technology, applied in the field of coatings, can solve the problems of short shelf life, weak adhesion, and high temperature resistance, and achieve the effects of long shelf life, strong adhesion, and no toxic and side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

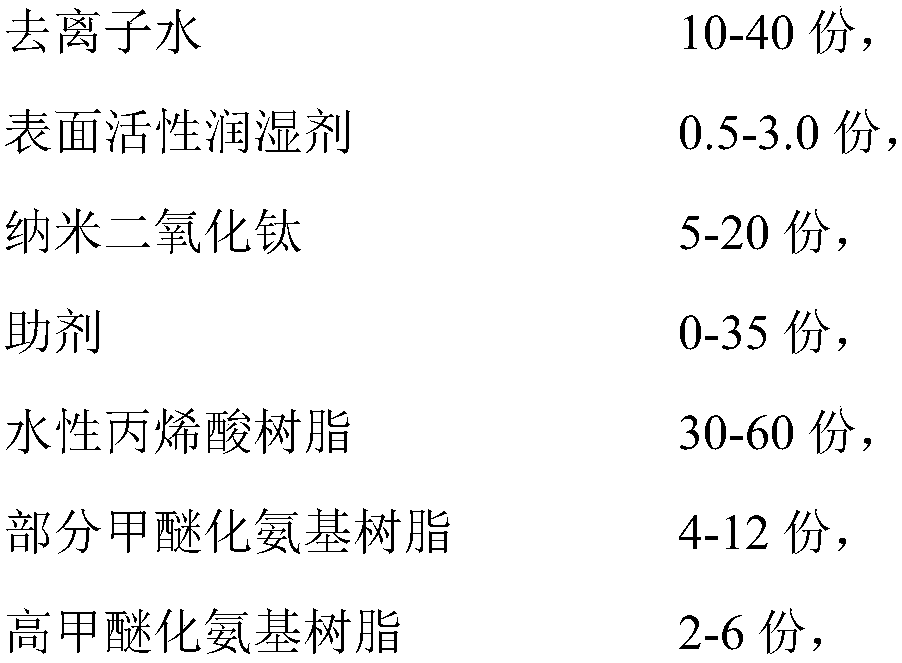

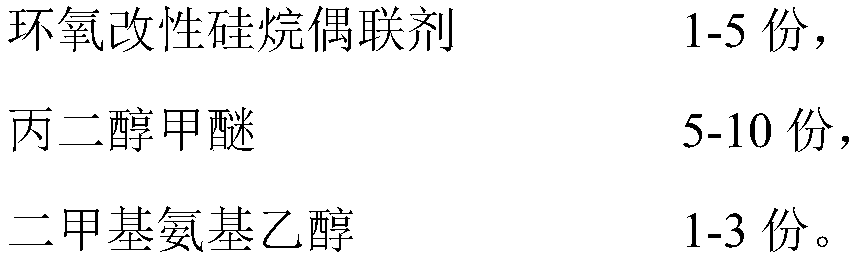

[0032] A high-temperature-resistant mildew-proof and antibacterial nano-water-based baking varnish, comprising the following components in parts by weight:

[0033]

[0034] The preparation method of the high-temperature-resistant mildew-proof and antibacterial nano water-based baking varnish comprises the following steps:

[0035] Weigh the surface active wetting agent, nano-titanium dioxide, additives, and water-based acrylic resin in parts, then add deionized water A, stir evenly, and then disperse at high speed until the fineness is below 10 microns, and then add part of methyl etherified amino resin , high methyl etherified amino resin, epoxy modified silane coupling agent, dimethylaminoethanol, propylene glycol methyl ether, deionized water B, stir evenly, and pack after passing the test.

[0036] The shelf life of the product of this embodiment can reach more than 36 months, and it will not decompose or change color when baked at 180 degrees Celsius for more than 60 ...

Embodiment 2

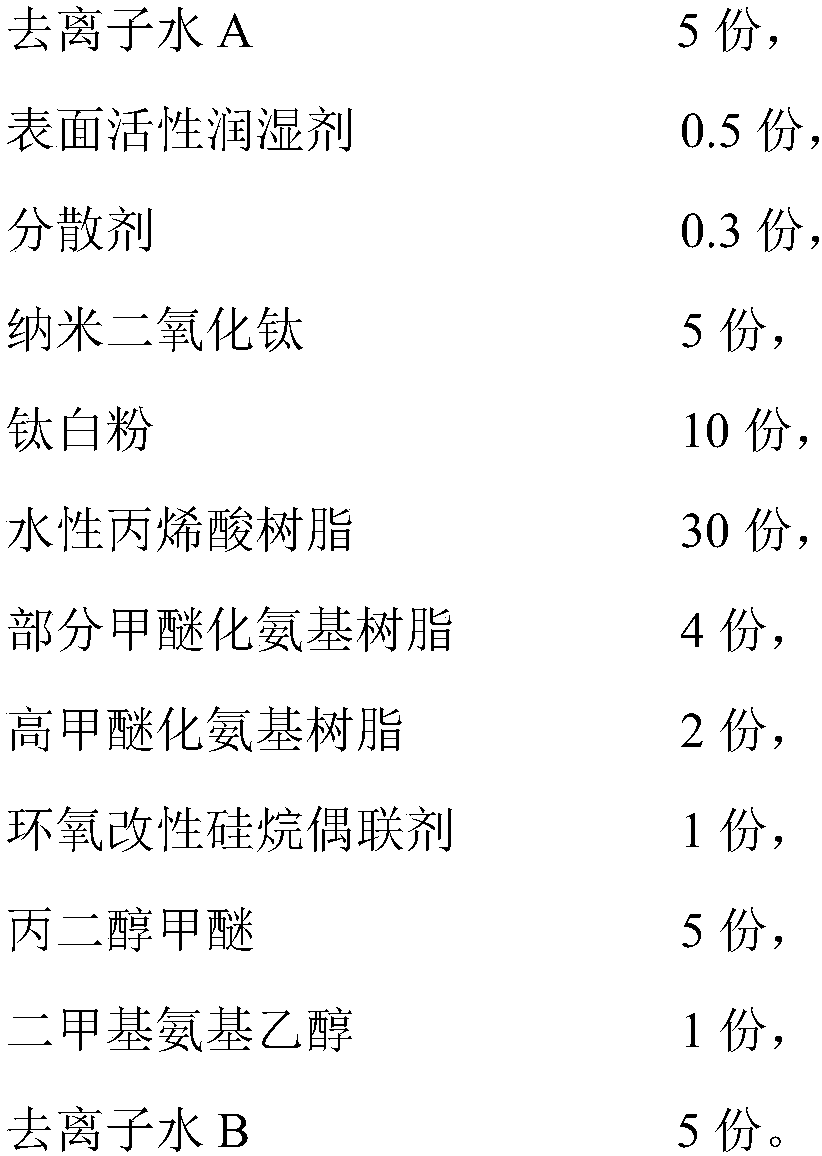

[0038] A high-temperature-resistant mildew-proof and antibacterial nano-water-based baking varnish, comprising the following components in parts by weight:

[0039]

[0040]The preparation method of the high-temperature-resistant mildew-proof and antibacterial nano water-based baking varnish comprises the following steps:

[0041] Weigh the surface active wetting agent, nano-titanium dioxide, additives, and water-based acrylic resin in parts, then add deionized water A, stir evenly, and then disperse at high speed until the fineness is below 10 microns, and then add part of methyl etherified amino resin , high methyl etherified amino resin, epoxy modified silane coupling agent, dimethylaminoethanol, propylene glycol methyl ether, deionized water B, stir evenly, and pack after passing the test.

[0042] The shelf life of the product of this embodiment can reach more than 36 months, and it will not decompose or change color when baked at 180 degrees Celsius for more than 60 m...

Embodiment 3

[0044] A high-temperature-resistant mildew-proof and antibacterial nano-water-based baking varnish, comprising the following components in parts by weight:

[0045]

[0046]

[0047] The preparation method of the high-temperature-resistant mildew-proof and antibacterial nano water-based baking varnish comprises the following steps:

[0048] Weigh the surface active wetting agent, nano-titanium dioxide, additives, and water-based acrylic resin in parts, then add deionized water A, stir evenly, and then disperse at high speed until the fineness is below 10 microns, and then add part of methyl etherified amino resin , high methyl etherified amino resin, epoxy modified silane coupling agent, dimethylaminoethanol, propylene glycol methyl ether, deionized water B, stir evenly, and pack after passing the test.

[0049] The shelf life of the product of this embodiment can reach more than 36 months, and it will not decompose or change color when baked at 180 degrees Celsius for m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com