Treatment technology for realizing colorful effect on surface of aluminum alloy part

A processing technology and aluminum alloy technology, which is applied in the field of processing technology to achieve colorful effects on the surface of aluminum alloy parts, can solve the problems of general coloring effect, single appearance of aluminum alloy products, and inability to achieve colorful effects, etc., to achieve beautiful appearance, good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention discloses a treatment process for realizing a colorful effect on the surface of an aluminum alloy part, which includes the following steps:

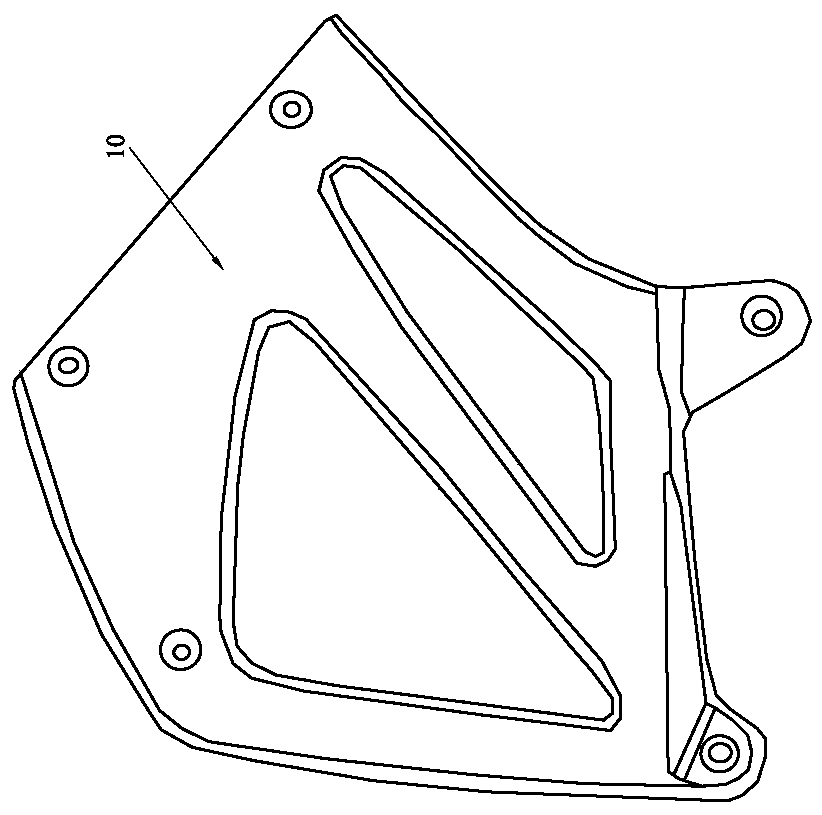

[0031] (1) Pearl chrome is electroplated on the surface of the aluminum alloy part 10 .

[0032] (2) Pre-cleaning the aluminum alloy part 10 after electroplating with pearl chrome. Specifically, pre-cleaning includes the following steps:

[0033] 1) Ultrasonic degreasing: use metal degreasing powder, the concentration is 8-10%, the temperature is controlled at 80-90°C, and the time is 2-3 minutes;

[0034] 2) The first water washing: use clean water, the pH is 7.5, the temperature is controlled at 20-40°C, and the time is 3-4 minutes;

[0035] 3) Ultrasonic wax removal: use metal wax remover, the concentration is 8-10%, the temperature is controlled at 80-90°C, and the time is 2-3 minutes;

[0036] 4) The second water washing: use clean water, the pH is 7.5, the temperature is controlled at 20-40°C, and the time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com