Filter structure of flocculation module and washing machine

A filter structure and modular machine technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve problems such as unfavorable transportation, recycling, water cannot be stored, and large size, and achieve suitable promotion and use, remarkable effect, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

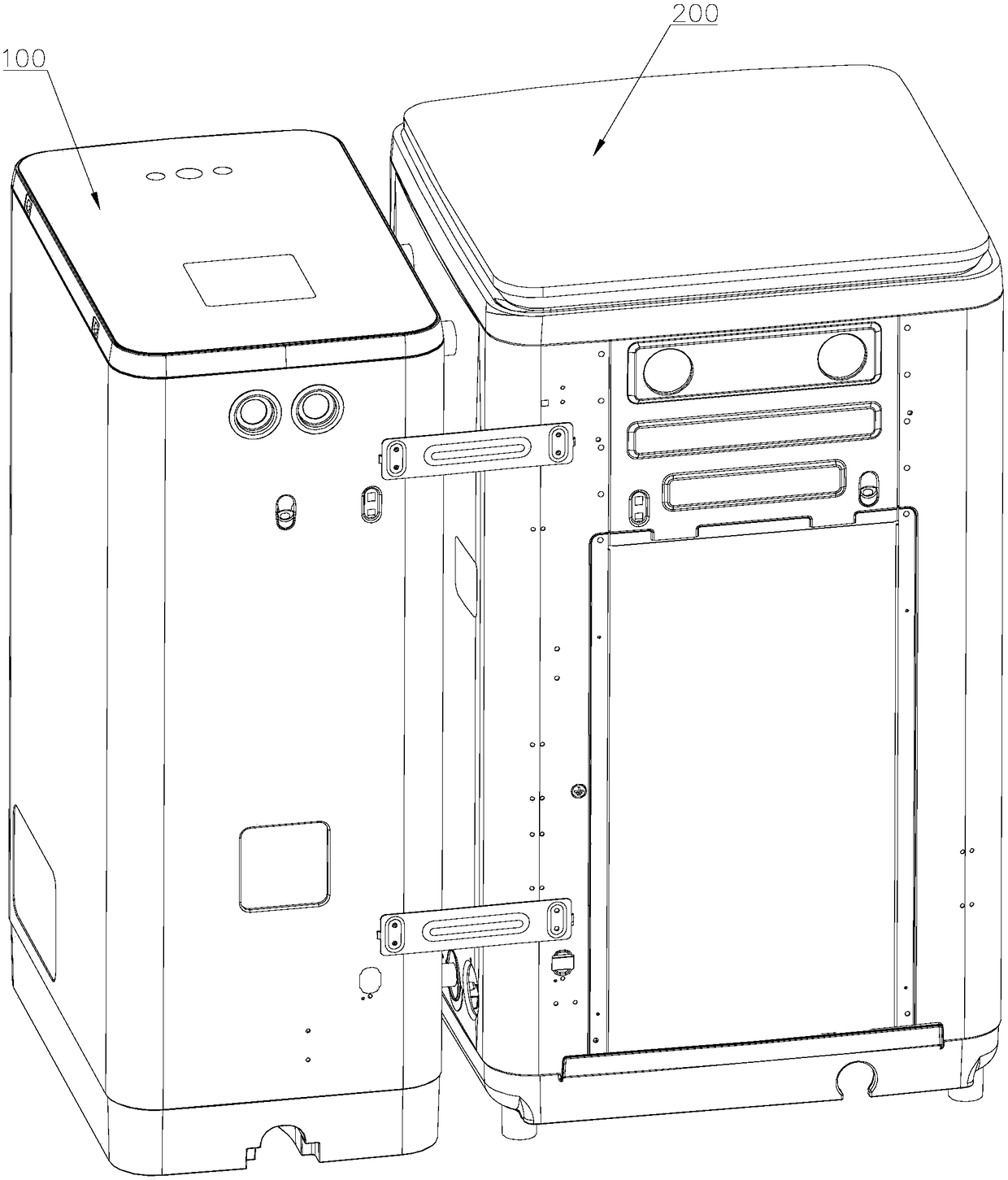

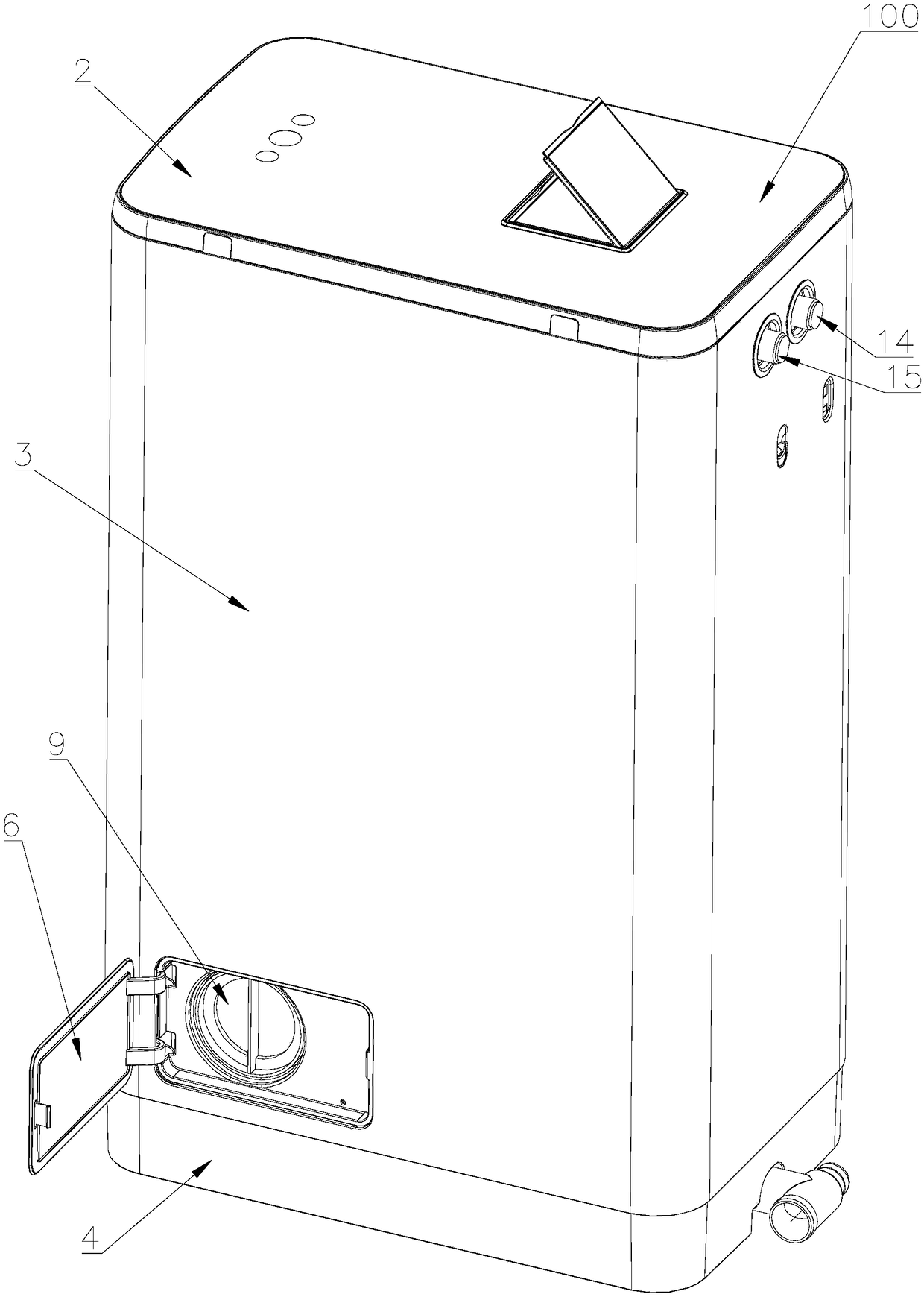

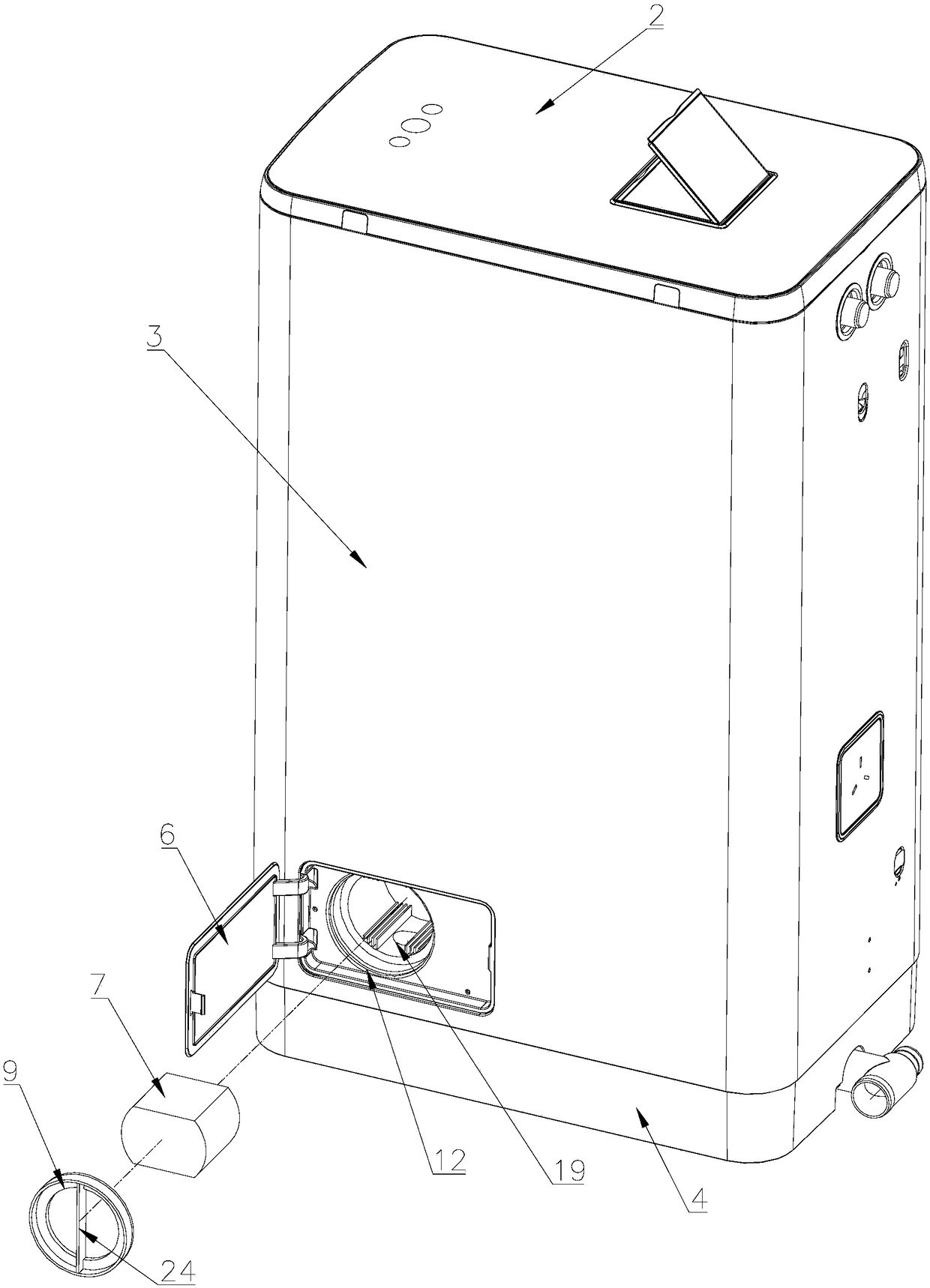

[0047] like Figure 1 to Figure 8 As shown, in this embodiment, the top opening of the flocculation bucket 1 is set, and the water baffle 5 arranged horizontally is arranged in the flocculation bucket 1, and the outer periphery of the water baffle 5 is in contact with the inner wall of the flocculation bucket 1, so that the water baffle 5 The flocculation bucket 1 is divided into upper and lower parts independent of each other, and a chamber for installing power supply devices is formed between the water baffle 5 and the control panel base 2 . . Preferably, the water baffle 5 is arranged on or near the top of the flocculation bucket 1, so as to maximize the internal space of the flocculation bucket 1 and increase the capacity of the flocculation bucket.

[0048] By setting a water baffle at the top opening of the flocculation bucket, the water in the flocculation bucket is prevented from being stirred and splashed out of the flocculation bucket; at the same time, the chamber ...

Embodiment 2

[0059] like Figure 5 and Figure 8 As shown, in this embodiment, an air pressure chamber 18 is provided on the outside of the flocculation bucket 1, the bottom of the air pressure chamber 18 communicates with the bottom of the flocculation bucket 1, and a pressure sensor is provided on the top of the air pressure chamber 18 to monitor the gas pressure in the air pressure chamber 18. Detection; preferably, the processing unit on the flocculation 100 converts the detected pressure value of the pressure sensor into the water level value in the flocculation bucket 1 , and then can accurately detect the water level of the flocculation bucket 1 .

[0060] In this embodiment, a control circuit board constituting a processing unit is installed on the control panel base 2, and the control circuit board is electrically connected to the pressure sensor in the air pressure chamber 18, so that the control circuit board can accept the detection signal of the pressure sensor to obtain The ...

Embodiment 3

[0062] like figure 1 , Figure 5 to Figure 13 As shown, a filter structure of a flocculation module is introduced in this embodiment. The top of the casing 3 of the flocculation module 100 is composed of a control panel seat 2, and a filter structure is installed on the lower side of the control panel seat 2. The filter structure includes a filter structure installed on the control panel The filter cavity 19 on the seat 2 is provided with a filter core 7 in the filter cavity 19, and the control panel base 2 is provided with a filter cover 6 that can be opened and closed for the filter core to take and place.

[0063] Through the above settings, an openable and closable filter cover is provided on the top control plate seat of the flocculation module to disassemble and replace the filter element in the filter structure, which facilitates the user's operation; at the same time, during the assembly process of the flocculation module, only Install the filter structure directly on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com