First-type lithium bromide heat pump unit provided with peak-load calorifier and capable of realizing direct heating

A technology of heat pump units and lithium bromide, which is applied in heat pumps, heating methods, household heating, etc., can solve the problems of heat pumps not being able to supply heat, investment waste, waste heat recovery, etc., to increase the heat supply of heat pumps, reduce the area of machine rooms, The effect of reducing the amount of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

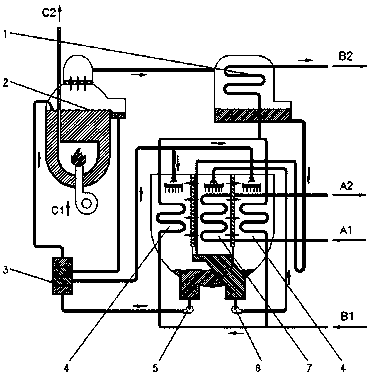

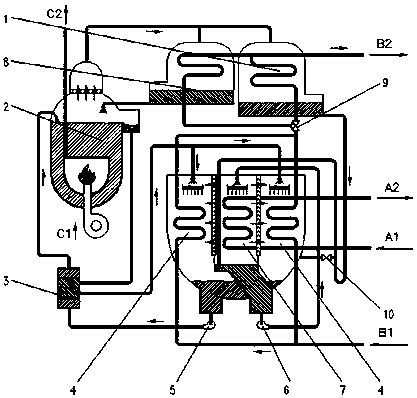

[0014] figure 2 It is an application example diagram of the first type lithium bromide heat pump unit (hereinafter referred to as the unit) with peak heating that can directly supply heat. The unit is composed of condenser 1, generator 2, heat exchanger 3, and absorber 4. Solution pump 5, refrigerant pump 6, evaporator 7, peak heater 8, hot water regulating valve 9, refrigerant regulating valve 10 and control system (not shown in the figure) and pipes and valves connecting various components Constituted. The residual hot water flows through the evaporator 7, the hot water first flows through the absorber 4, and then flows through the condenser 1 and the peak heater 8 in parallel. The hot water regulating valve 9 adjusts the amount of hot water flowing through the peak heater 8 to drive the heat The source flows through the high voltage generator 2. When the unit is running and there is excess hot water, the refrigerant regulating valve 10 is closed, and the refrigerant water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com