LED chip strength test device

A technology of LED chip and strength testing, applied in the direction of measuring device, strength characteristics, and testing the strength of materials by applying a stable bending force, it can solve the problems of abnormal LED chip breakage, affecting the customer experience effect of packaging product yield, etc., to achieve The effect of reducing LED chip breakage, improving accuracy and safety, and ensuring test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

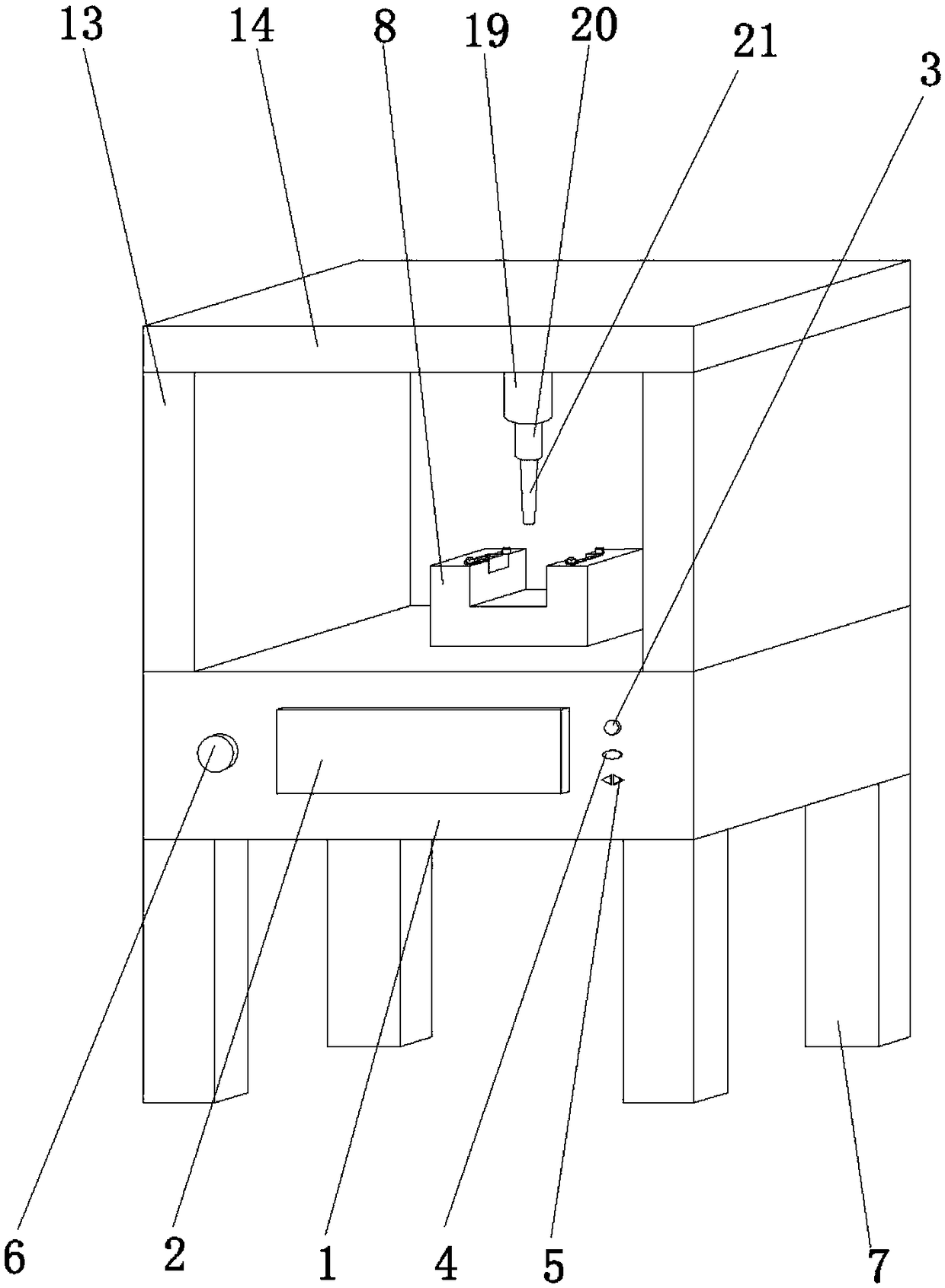

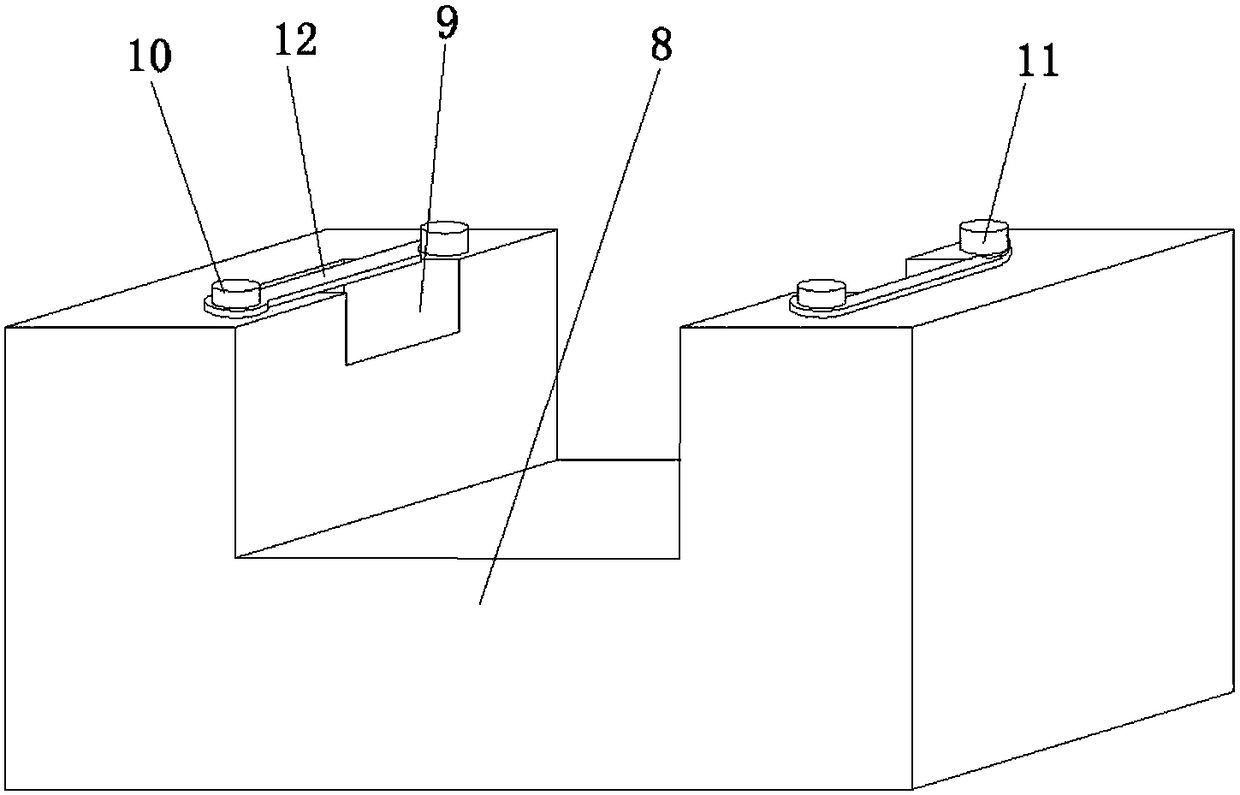

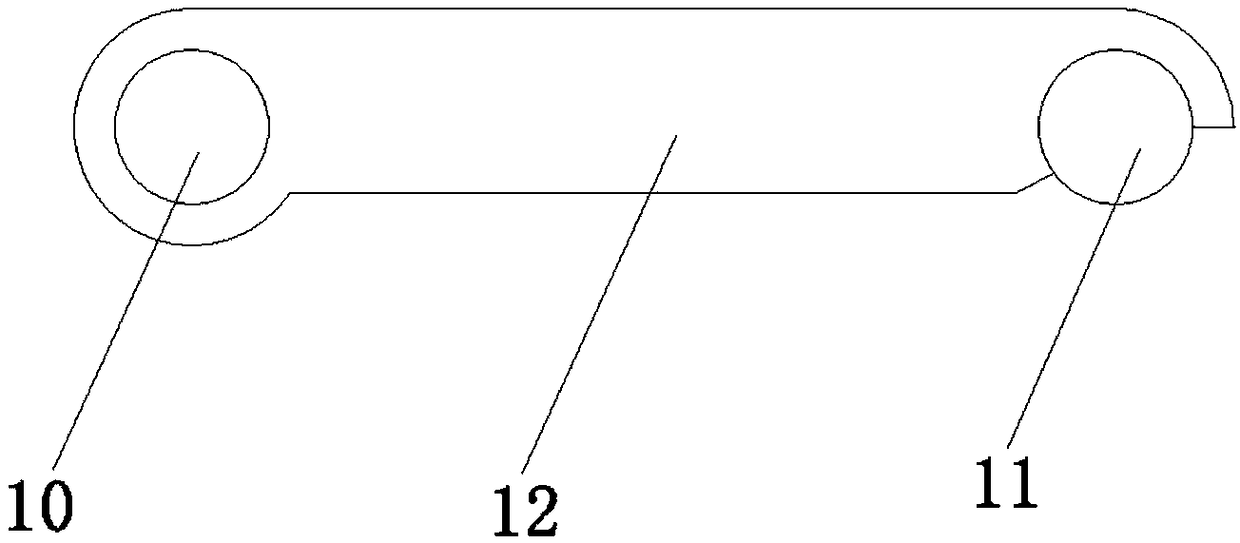

[0022] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] combine Figure 1 to Figure 6 , a kind of LED chip strength testing device, comprises device body, and device body comprises console 1, and console 1 is provided with control module and button module, and the front center of console 1 is provided with liquid crystal display 2, liquid crystal display 2 There is a button area on one side of the side, the button area includes the power button 3, the state control button 4 and the pressure setting button 5, the power button 3, the status control button 4 and the pressure setting button 5 are all electrically connected to the button module, and the liquid crystal display The other side of the screen 2 is provided with an indicator light 6, the back of the console 1 is provided with a power cord, the bottom of the console 1 is provided with support legs 7, and the number of suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap