LED chip anti-breaking strength testing device

A LED chip and strength testing technology, which is applied in the direction of measuring devices, strength characteristics, and the use of stable bending force to test the strength of materials, etc., can solve problems such as LED chip breakage abnormalities, affecting the packaging product yield rate, and customer experience effects, to achieve Reduce LED chip breakage, improve accuracy and safety, and ensure test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

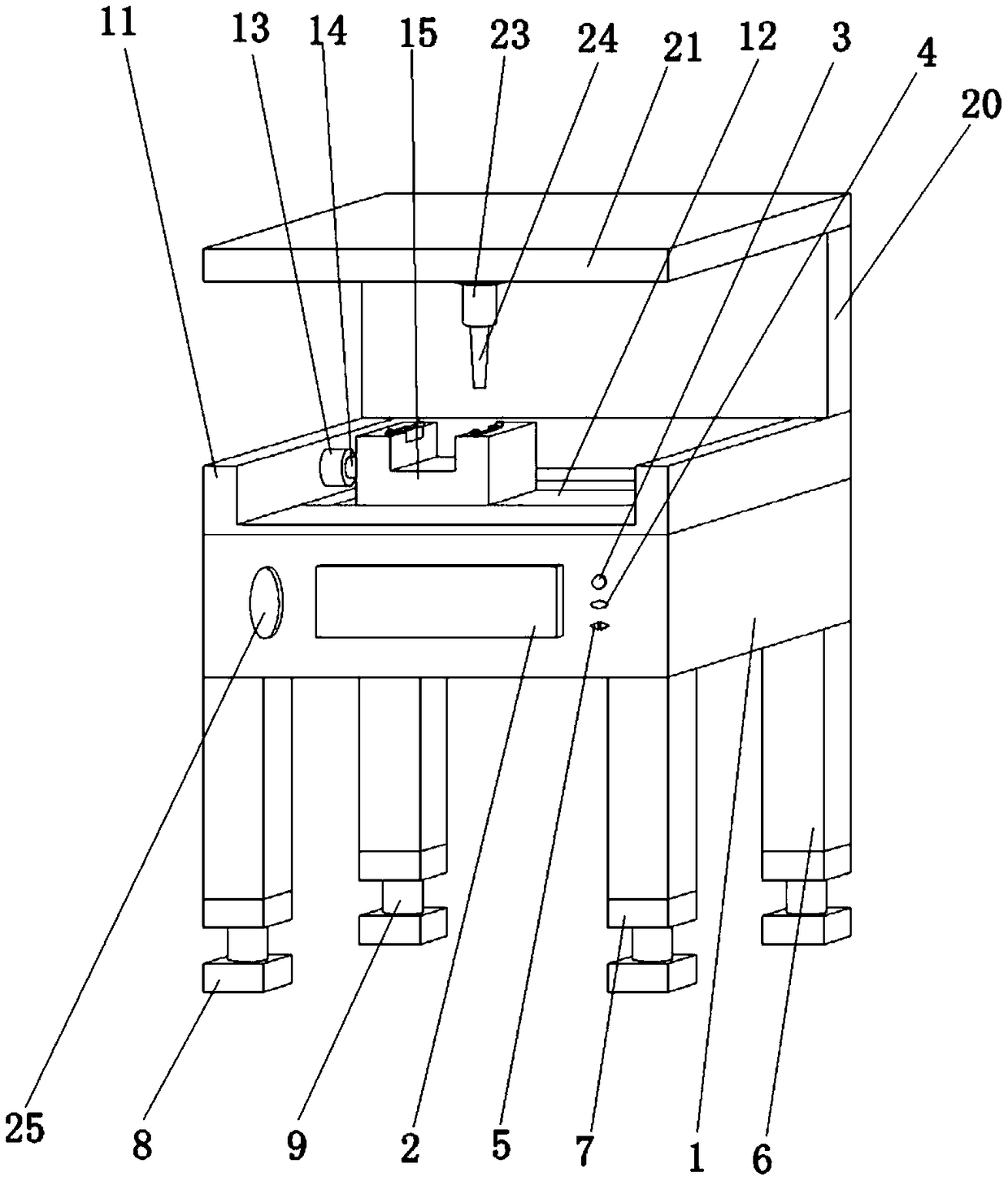

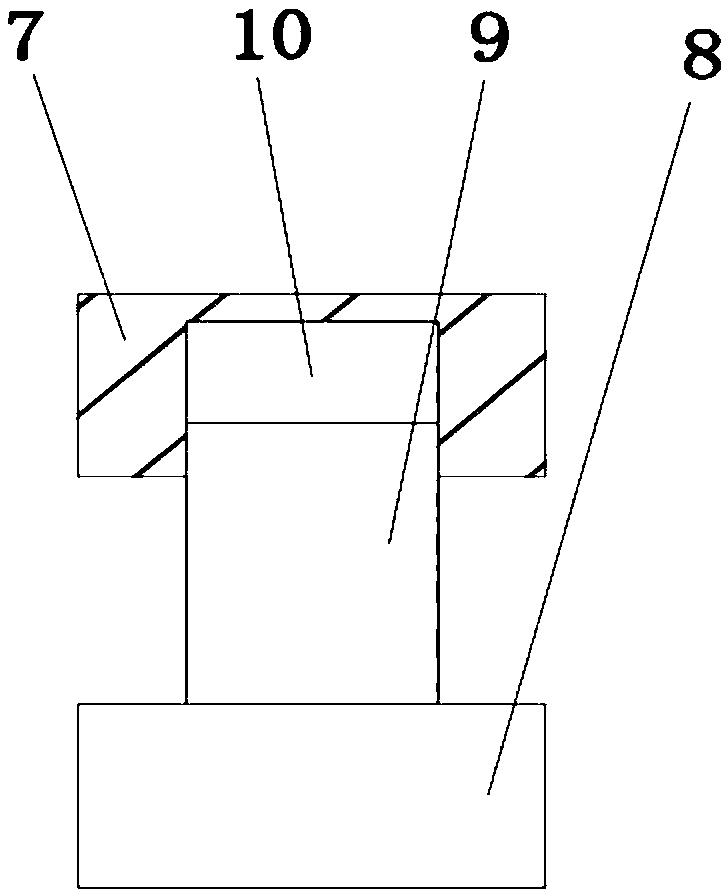

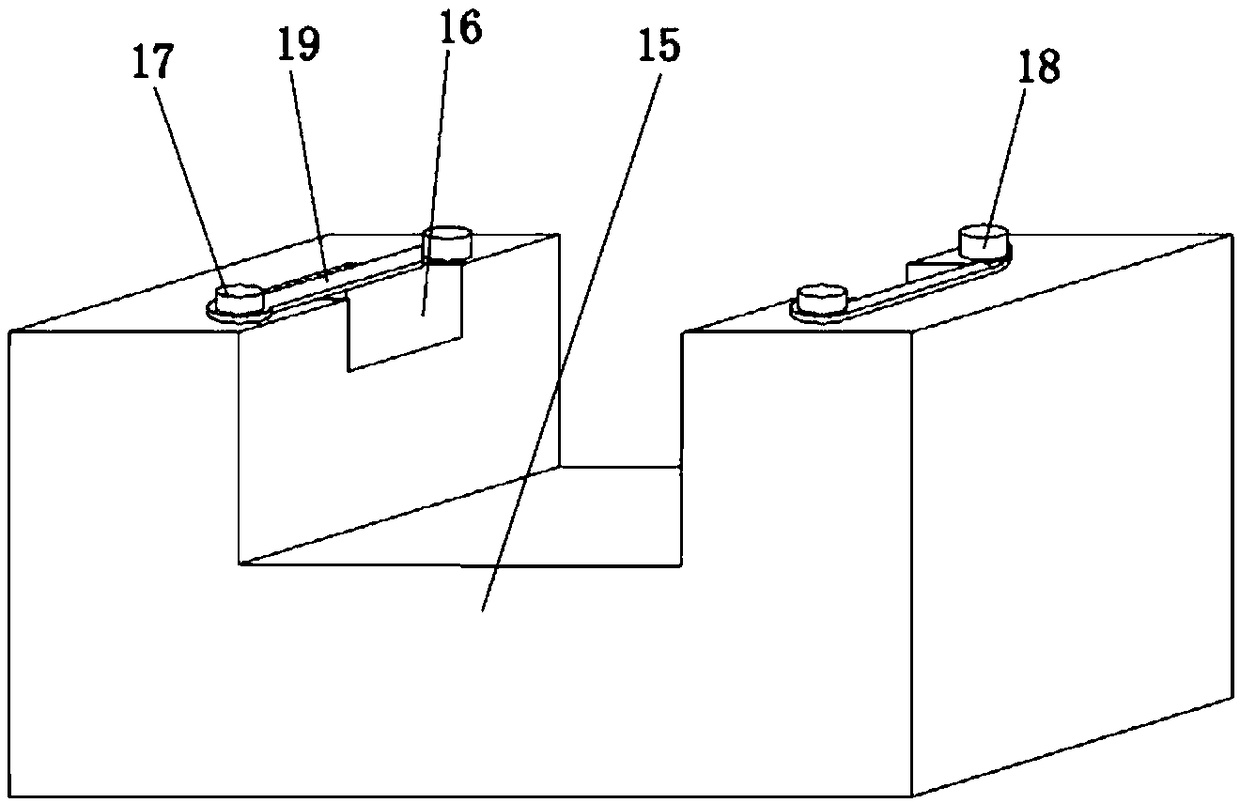

[0022] combine Figure 1 to Figure 6, a LED chip anti-fracture strength testing device, including a device body, the device body includes a console 1, a control module and a button module are arranged in the console 1, and a liquid crystal display 2 is arranged in the center of the front of the console 1, and the liquid crystal display One side of the screen 2 is provided with a key area, the key area includes a power key 3, a state control key 4 and a pressure setting key 5, and the power key 3, state control key 4 and pressure setting key 5 are all electrically connected to the key module, The other side of liquid crystal display screen 2 is provided with buzzer 25, and the back side of console 1 is provided with power cord, and the bottom of console 1 is provided with support leg 6, and the quantity of support leg 6 is four, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap