Bionic three-dimensional scaffold for promoting bone defect repair and preparation method thereof

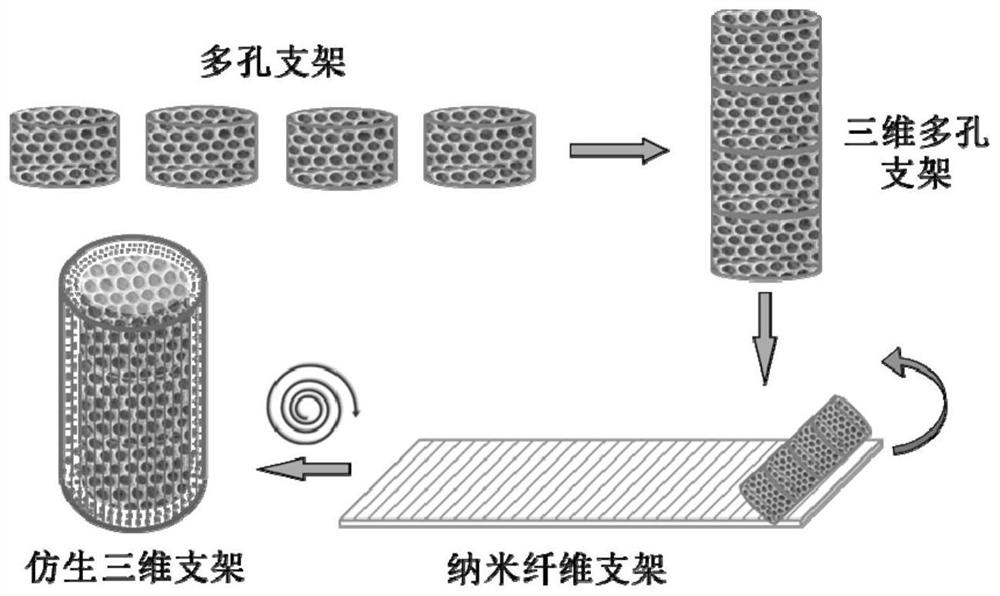

A technology for three-dimensional scaffolds and bone defects, applied in the field of bionic three-dimensional scaffolds and their preparation, can solve the problems of difficult control of inter-lamellar spacing, unfavorable adhesion and proliferation of bone marrow penetrating cells, preventing displacement or even scattering, facilitating cell adhesion and proliferation, Size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Obtaining of PLGA electrospun nanofibers: 3g PLGA was dissolved in 100ml chloroform (CHCl 3 ) and N,N-dimethylformamide (DMF) mixed solution (volume ratio 3:1) to obtain a transparent solution, put it into a syringe, the syringe needle is flat, the inner diameter is 0.5mm, and the syringe is fixed on On the propulsion pump, the propulsion speed is set to 1.5ml / h, the positive pole of the high-voltage DC power supply is connected to the syringe needle, the negative pole is connected to the plate or roller collector, the voltage is 15kV, the collection distance is 25cm, the time is 1h, and the PLGA static electricity is obtained by vacuum drying at 30°C for 24h. Spun nanofibrous membrane (attached figure 2 ). (For specific methods, please refer to Colloids and Surfaces B: Biointerfaces2018, 167, 550-559)

[0027] 2. The acquisition of the PLGA porous support: collect gelatin microspheres with a microfluidic device, and the microfluidic conditions are as follows: the...

Embodiment 2

[0030] It is basically the same as Example 1, except that the outer PLGA electrospun membrane is replaced by a PHBV electrospun membrane. 0.9g PHBV and 0.1g polyoxyethylene (PEO) were dissolved in 50ml trifluoroethanol (TFE); the solution was added to the syringe, the needle of the syringe was flat and the inner diameter was 0.5mm, the syringe was fixed on the propulsion pump, and the propulsion speed was set to 5ml / h, the positive electrode of the high-voltage DC power supply is connected to the needle of the syringe, and the negative electrode is received by the collector. The voltage is 12kV, and the collection distance is 25cm. After 2h, the obtained PHBV nanofiber membrane is removed, and vacuum-dried at 30°C for 24h to obtain PHBV electrospun fibers membrane. (The specific method can refer to the patent ZL201110037596.9)

Embodiment 3

[0032] It is basically the same as Example 1, except that the outer layer of PLGA nanofibers is doped with nano-sized hydroxyapatite (nHA). Dissolve 3 g PLGA in 75 ml CHCl 3 0.3g nHA was ultrasonically dispersed in DMF, and then the two were mixed and stirred evenly as an electrospinning solution, and PLGA / nHA nanofibers were obtained under the same conditions as in Example 1. (For specific methods, please refer to ACS Appl.Mater.Interfaces 2013,5,319-330)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com