lubricant composition

A lubricant composition and compound technology, applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of not so good wear prevention performance and limited service life, so as to achieve excellent engine wear performance, prevent rapid rise, The effect of improving friction performance

Inactive Publication Date: 2019-12-03

SK INNOVATION CO LTD +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In particular, the presence of phosphorus in ZnDDP has the problem of limiting the service life of catalytic converters used in automobiles for pollution reduction

In addition, the lubricant containing only ZnDDP as an anti-wear additive has a problem that the anti-wear performance of bearings and engines is not so good.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~12

[0069] (1) Embodiment 1~12 (add aminomolybdenum nano-compound)

[0070] table 5

[0071]

Embodiment 13~24

[0072] (2) Examples 13-24 (addition of ester molybdenum nano-compounds)

[0073] Table 6

[0074]

[0075]

Embodiment 25~36

[0076] (3) Examples 25-36 (addition of ester tungsten nano-compounds)

[0077] Table 7

[0078]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a lubricant composition which, unlike a conventional lubricant composition, has excellent effects of preventing abrasion and reducing friction. The lubricant composition of the invention comprises a base oil and a specific organometallic compound dissolved in the base oil. The organometallic compound can be completely dissolved in the base oil and has a storage stability of at least 6 months or more. Therefore, the lubricant composition is free from the limitation of the use amount due to the solubility. As the specific organometallic compound is contained, the lubricant composition has the effect of gaining a tremendous increase in the bearing wear resistance performance for engine protection as compared with a conventional lubricant, the engine cleanability is improved, the friction performance is also improved, and thus the effect of improving the fuel efficiency can be expected.

Description

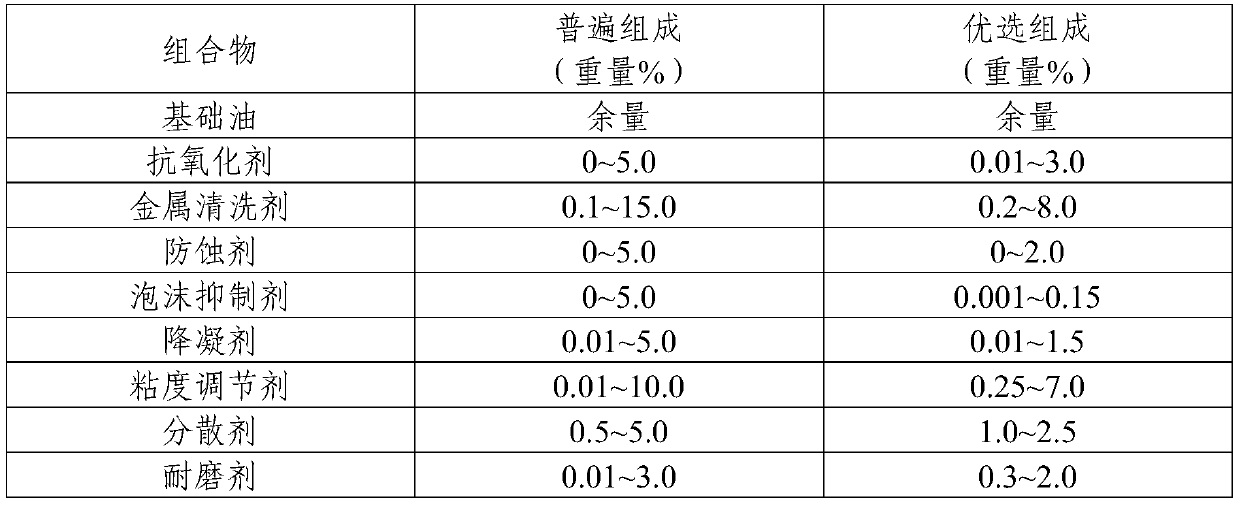

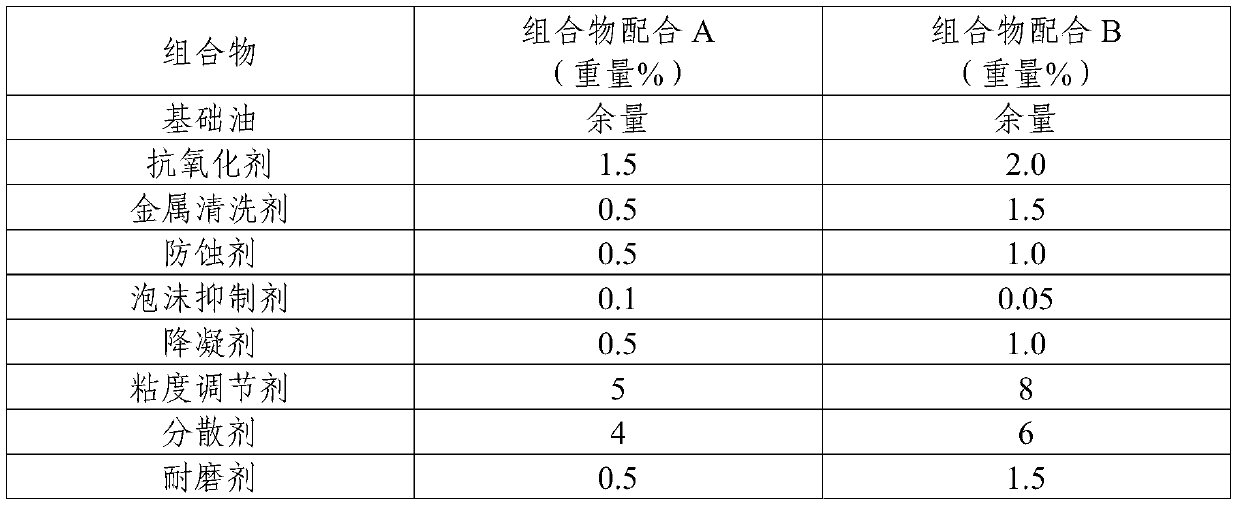

technical field [0001] The present invention relates to a lubricant composition, in particular to a lubricant composition comprising a base oil and a specific organometallic compound dissolved in the base oil so as to be suitable for engine protection performance Gasoline engine (gasoline engine) oil or diesel engine (diesel engine) oil with excellent engine wear performance. Background technique [0002] Lubricants are used in automotive engines, transmissions, bearings, gears, industrial gears, and other machinery to reduce friction and wear and improve fuel efficiency. Such lubricants generally include dispersants, cleaning agents, anti-wear agents, antioxidants, anti-corrosion agents, etc., and include various components that are not limited thereto. [0003] Such lubricants or lubricating oils serve to improve the operation of moving bodies by reducing friction and increasing efficiency between moving bodies while conserving required energy. [0004] Recently, attempt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M141/12C10M169/04C10M163/00C10N40/25C10N30/06C10N20/02

CPCC10M141/12C10M163/00C10M169/045C10M2227/08C10M2227/09C10N2020/02C10N2020/06C10N2030/06C10N2030/54C10N2040/10C10N2040/25

Inventor 李炯镇赵容来黄善爱

Owner SK INNOVATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com