A kind of method for improving traditional Chinese medicine or food raw material spray-drying hot-melt type sticking wall

A hot-melt and drying technology, applied in the direction of food drying, the function of food ingredients, and protein-containing food ingredients, etc., can solve the problems of small applicable window of spray drying process parameters, high requirements for equipment control, incomplete drying, etc. The effect of good clarity, great application value and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

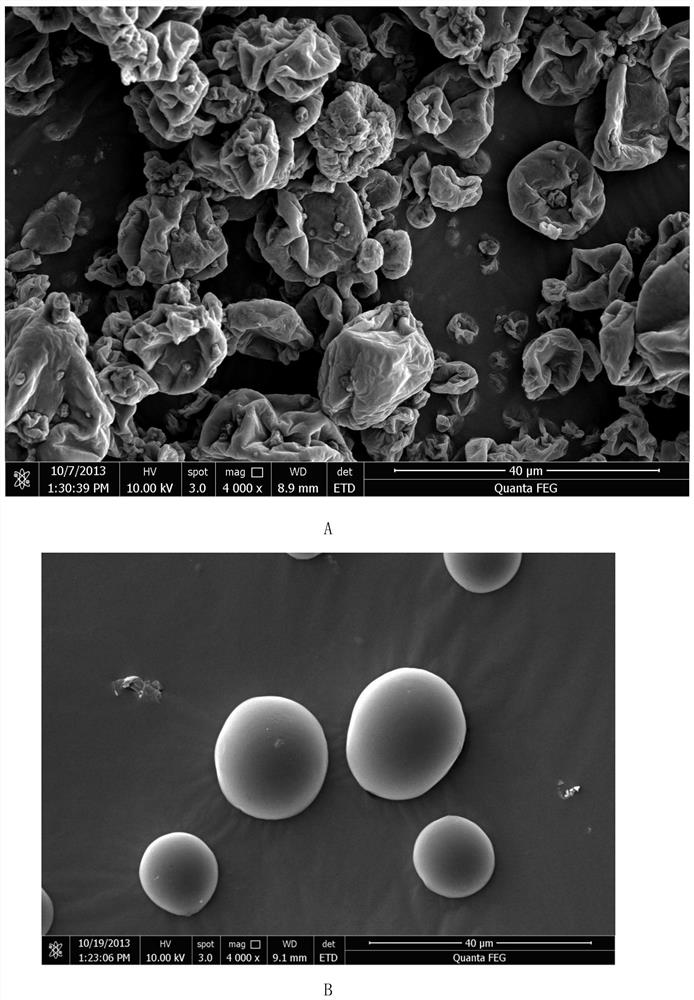

[0017] Embodiment 1: Improve the comparative example of spray-drying hot-melt type sticky wall of hawthorn extract

[0018] Hawthorn is a food with the same origin of medicine and food, and its water extract is often used alone or added to other medicines or foods, but the spray-drying process of the extract has serious hot-melt type sticking.

[0019] Hawthorn is properly extracted and concentrated to obtain an extract (solid content of 20%), which is divided into two equal parts, one of which is added with soybean peptide powder (model: soybean protein isolate, manufacturer: Shansong Biological Products Co., Ltd.), which accounts for 30% of the dry paste of the extract. Company, in line with the first-class standard of physical and chemical indicators of soybean peptide powder in GB / T 22492-2008), stir to make the dispersion uniform, and spray dry under stirring conditions (BUCHI-B290 spray dryer, the process parameters are set as: inlet air temperature 140℃, atomization pre...

Embodiment 2

[0020] Embodiment 2: Improve the comparative example of spray-drying hot-melt type sticky wall of jujube extract

[0021] Jujube is a food with the same origin of medicine and food, and its water extract has serious hot-melt type sticking during the spray-drying process.

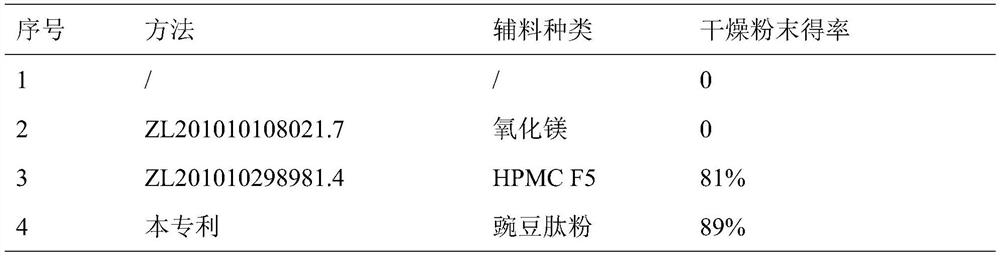

[0022] The jujube is properly extracted to obtain the extract, the solid content is adjusted to 2%, and the extract is divided into four parts on average. According to Table 1, add the corresponding auxiliary materials respectively (the addition amount of magnesium oxide is 5% of the dry paste of the extract, the addition amount of HPMC F5 is 15%, and the addition amount of pea peptide powder is 15%) and stir to make the dispersion uniform, and under stirring conditions spray drying (BUCHI-B290 spray dryer, the process parameters are set as: inlet air temperature 140°C, atomization pressure 1.05bar, liquid inlet velocity 9mL / min, inlet air volume 35m 3 / h). Pure jujube water extract and magnesium oxide-add...

Embodiment 3

[0025] Example 3: Improve the spray-drying hot-melt type sticky wall of Qiangli Ning extract

[0026] Qiangli Ningfang is a variety collected in the 10th volume of the "Medical Standard Chinese Medicine Formulations of the Ministry of Health". In the experiment, it was found that the hot-melt type sticking of the extract occurred during spray drying.

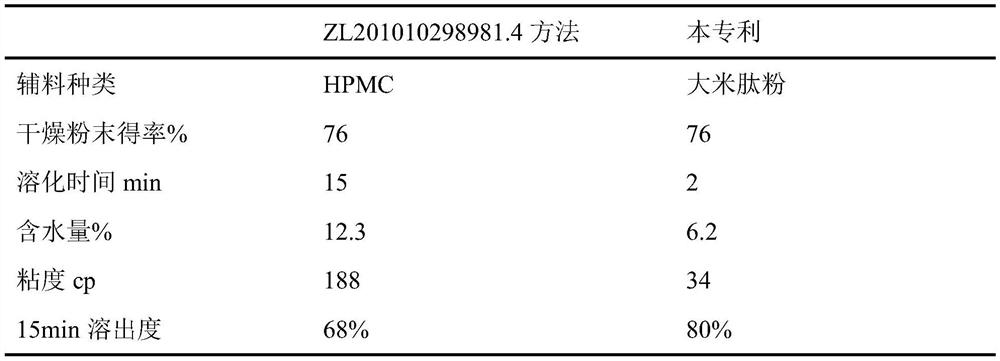

[0027]The difference in properties of the products obtained by comparing the method of patent ZL201010298981.4 and the method of this patent: Qiangli Ningfang is properly extracted and concentrated to obtain Qiangli Ningfang extract (solid content: 10%); it is divided into 3 parts on average, the first part is directly spray-dried, and the second part is directly spray-dried. Two parts were added with HPMC E3 which accounted for 20% of the solid content of the extract, and the third part was added with rice peptide powder which accounted for 20% of the solid content of the extract (Model: Rice Peptide Powder, Manufacturer: China...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com