Calculation method for elastoplastic deformation of a line contact rolling bearing

An elastic-plastic deformation and rolling bearing technology, applied in the field of rolling bearings, can solve problems such as bearing vibration, bearing surface fatigue failure, and failure to analyze elastic-plastic deformation of bearing parts, etc., to achieve the effect of improving reliability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

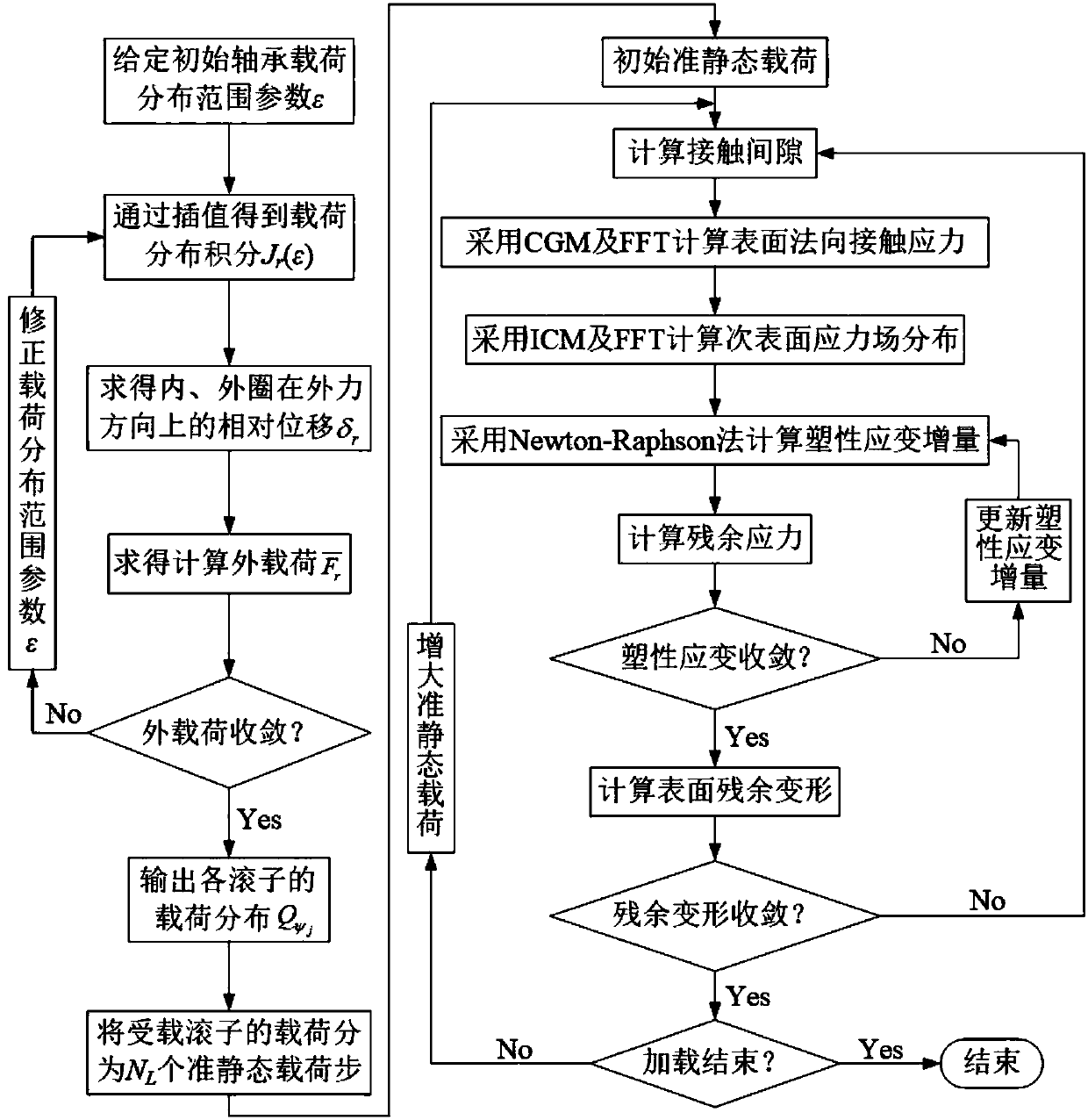

[0044] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

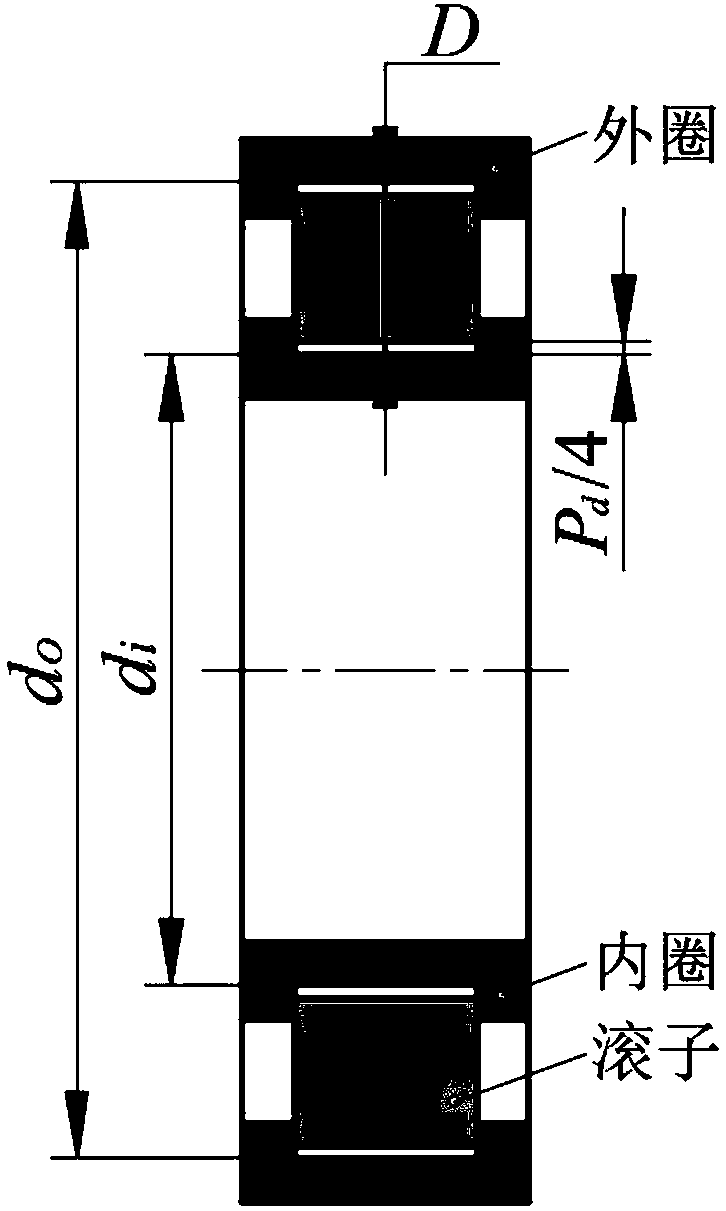

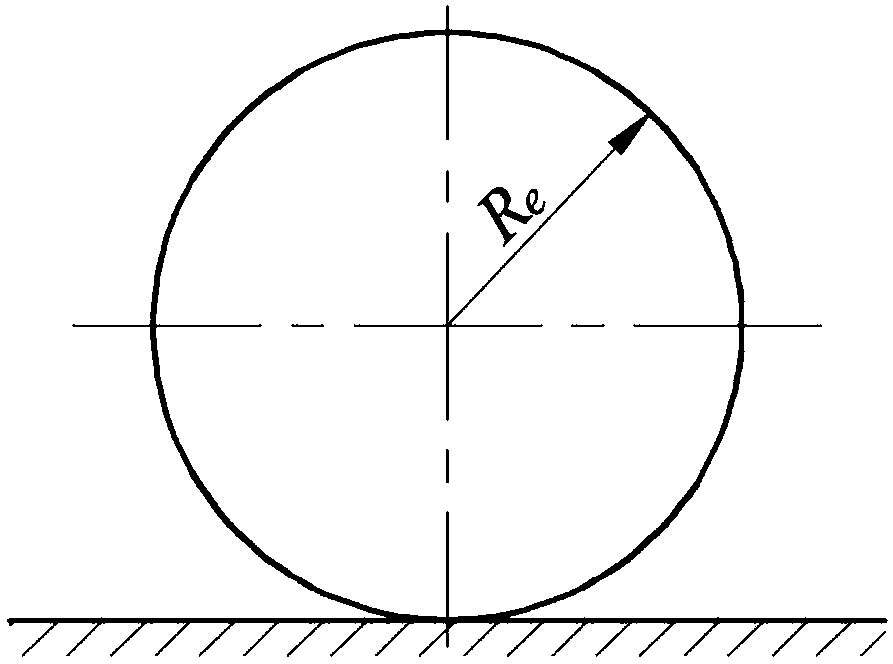

[0045] The two-dimensional diagram of a typical linear contact rolling bearing (taking cylindrical roller bearings as an example) is shown in figure 1 As shown, the diameter of the groove top of the inner ring is d i , the bottom diameter of the outer ring groove is d o , the radial clearance is P d , the diameter of the roller is D, and the number of rollers is Z. The contact problem of cylindrical roller bearings can be simply divided into two cases: the contact between the roller and the inner ring, and the contact between the roller and the outer ring, both of which belong to the contact problem between two cylinders. In general, the contact of two cylinders can be equivalent to a radius R e The contact of the equivalent cylinder with a half-space plane, such as figure 2 shown.

[0046] For the contact between the roller and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com