Convenient-to-maintain solar module structure

A solar module, a convenient technology, applied in the direction of electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of damage, detachment from the structure, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

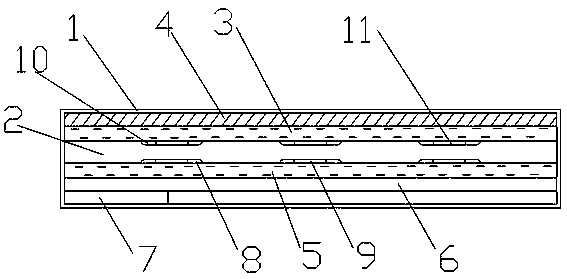

[0013] Such as figure 1 A solar module structure with easy maintenance is shown, including a rectangular parallelepiped frame 1, a silicon wafer battery 2 is arranged in the frame 1, the upper surface of the silicon wafer battery 2 is bonded to a glass plate 4 through the upper EVA adhesive layer 3, and the lower surface is passed through the lower EVA The adhesive layer 5 is bonded to the back plate 6, the bottom of the back plate 6 is provided with a junction box 7 connected to the silicon wafer battery 2, the lower surface of the silicon wafer battery is provided with a groove 8, and a support block 9 is fixed in the groove 8, and the support block 9 The end part is connected with the lower EVA adhesive layer 5, the silicon wafer battery groove is provided with a counterbore, and the support block is provided with a through hole, and the support block and the groove are fixed through the through hole and the counterbore through nuts or screws, The upper surface of the silic...

Embodiment 2

[0015] Referring to Example 1, the upper surface of the silicon wafer battery is provided with a groove 2 10, a support block 2 11 is fixed in the groove 2 10, and the end of the support block 11 is connected to the upper EVA adhesive layer 3, and the silicon wafer battery The groove 2 is provided with a counterbore 2, and the support block 2 is provided with a through hole 2, and the support block 2 and the groove 2 pass through the through hole 2 and the counterbore 2 through nuts or screws and are fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com