Mechanical part cleaning device

A technology for mechanical parts and cleaners, applied in mechanical equipment, springs/shock absorbers, chemical instruments and methods, etc., to achieve the effect of increasing stability and improving shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

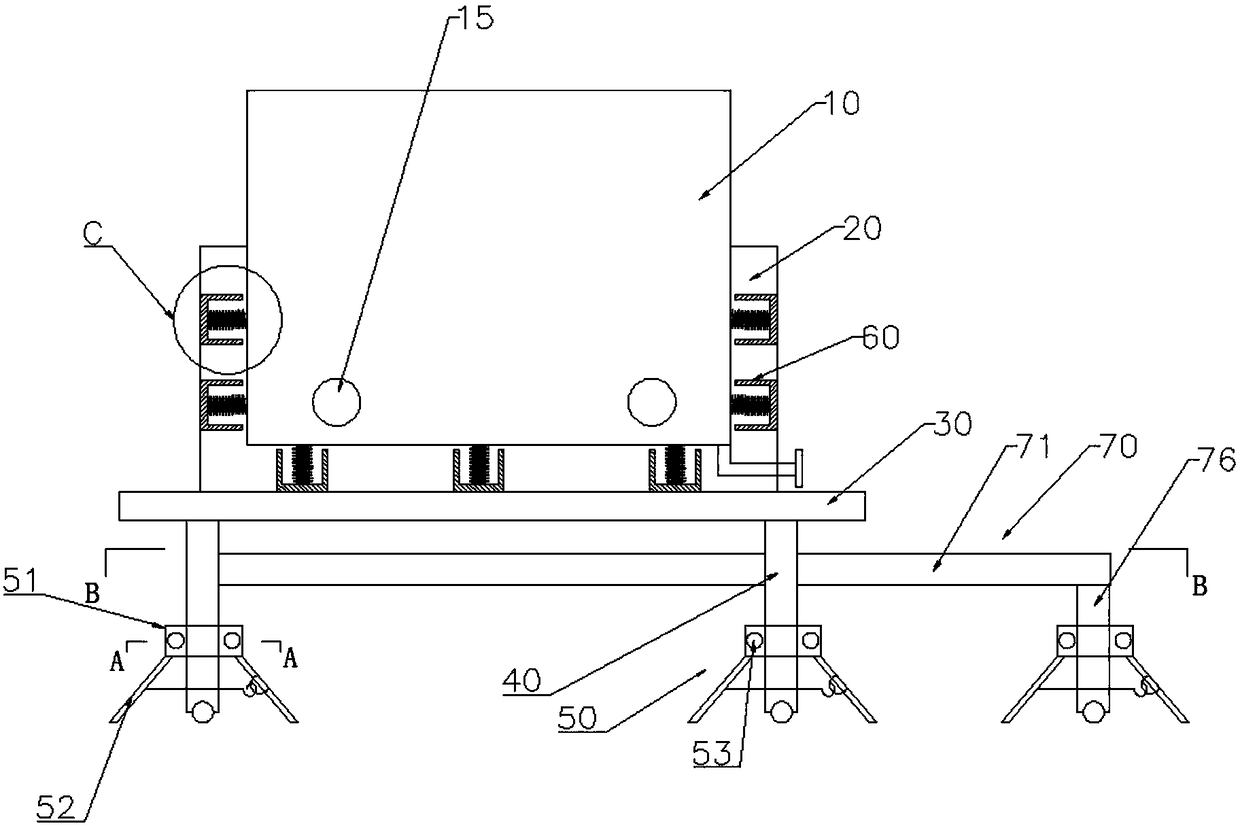

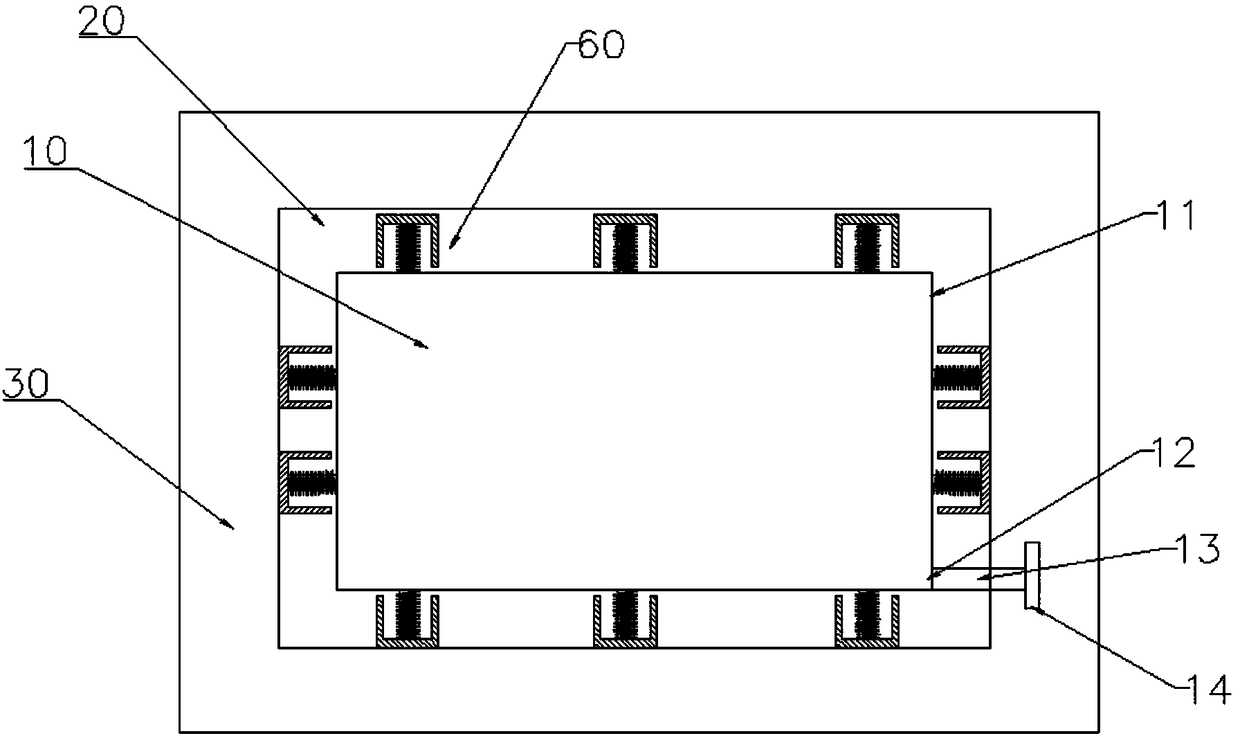

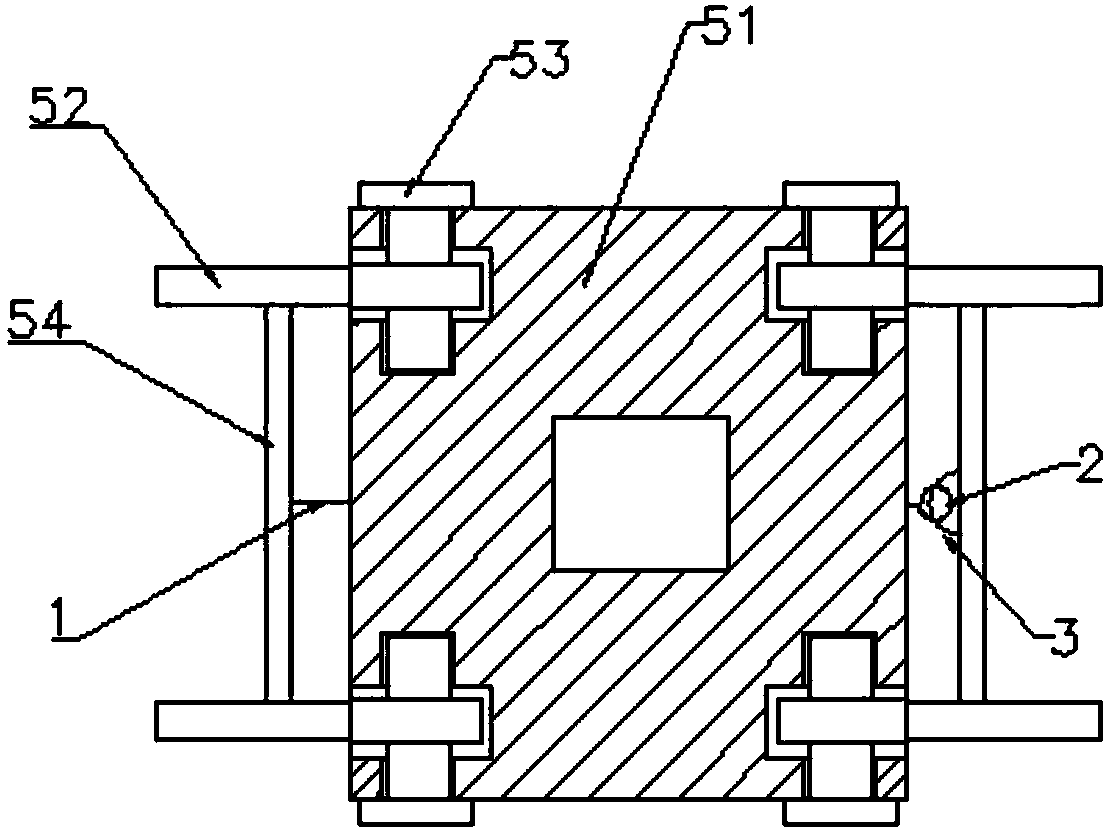

[0023] combine Figure 1 to Figure 8 A kind of mechanical parts washer shown, in this embodiment, includes a washer body 10, an outer shell 20 surrounding the outer side of the washer body 10, a support plate 30 arranged at the bottom of the outer shell 20, and a supporting plate 30. Four support legs 40 distributed in a rectangular shape, an auxiliary bracket 50 arranged on the support legs 40 and a shock absorber 60 arranged between the washer body 10 and the outer shell 20, the bottom of the support legs 40 are provided with a second A pulley, the auxiliary bracket 50 includes a rectangular cover plate 51 sleeved and fixed on the supporting leg 40, auxiliary legs 52 connected to the four corners of the cover plate 51 and bolts 53 connecting the cover plate 51 and the auxiliary leg 52, The top of the auxiliary leg 52 is provided with a through hole, and the cover plate 51 is provided with a groove for accommodating the top of the leg, and both sides of the groove are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com