Water milling device for rubber plates

A rubber sheet and water grinding technology, applied in the direction of grinding/polishing safety devices, grinding machines, abrasive belt grinders, etc., can solve the problems of low work efficiency, poor working environment, time-consuming and labor-intensive abrasive belts, etc., so as to improve the processing effect and replace Convenience and speed, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

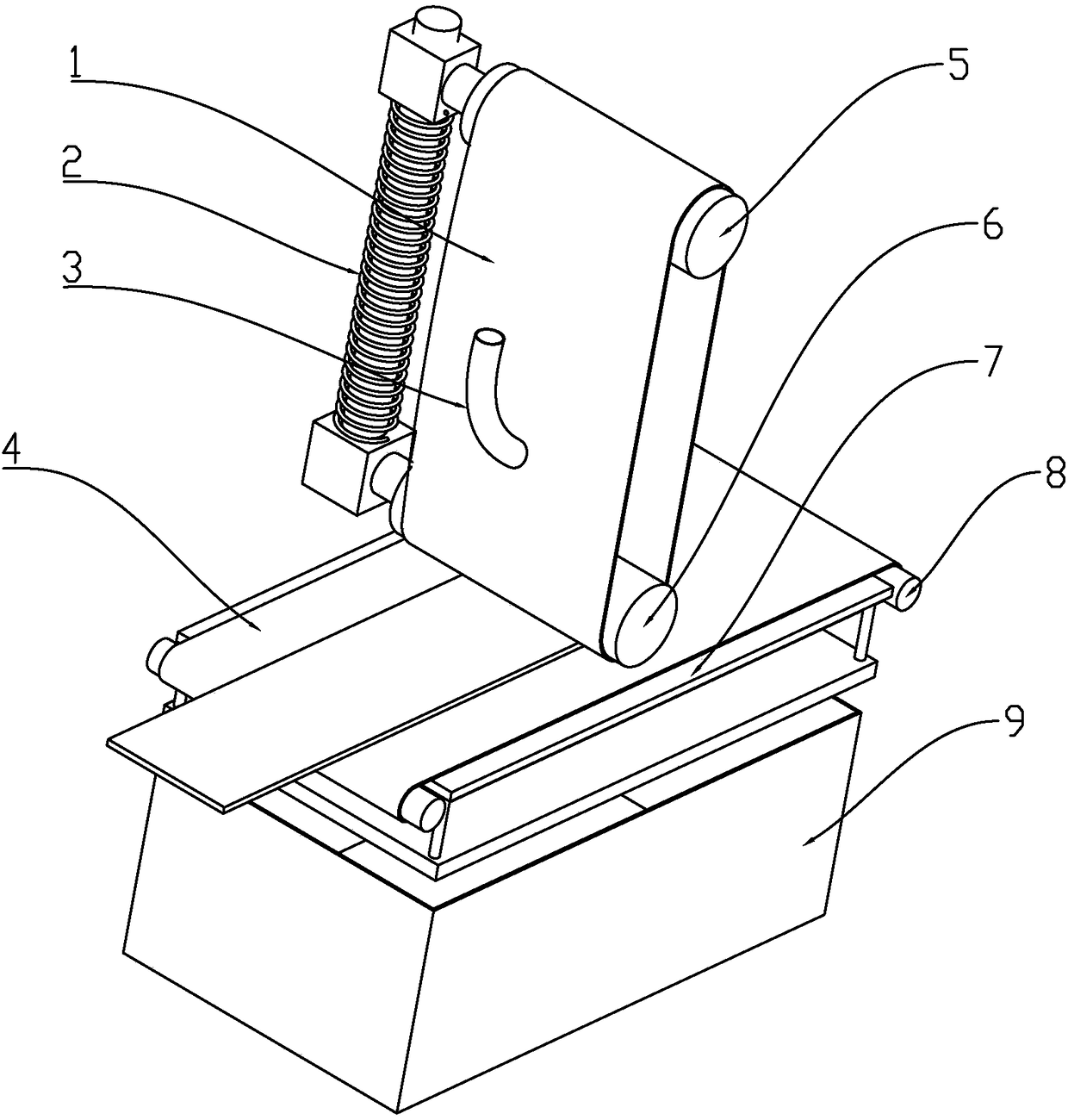

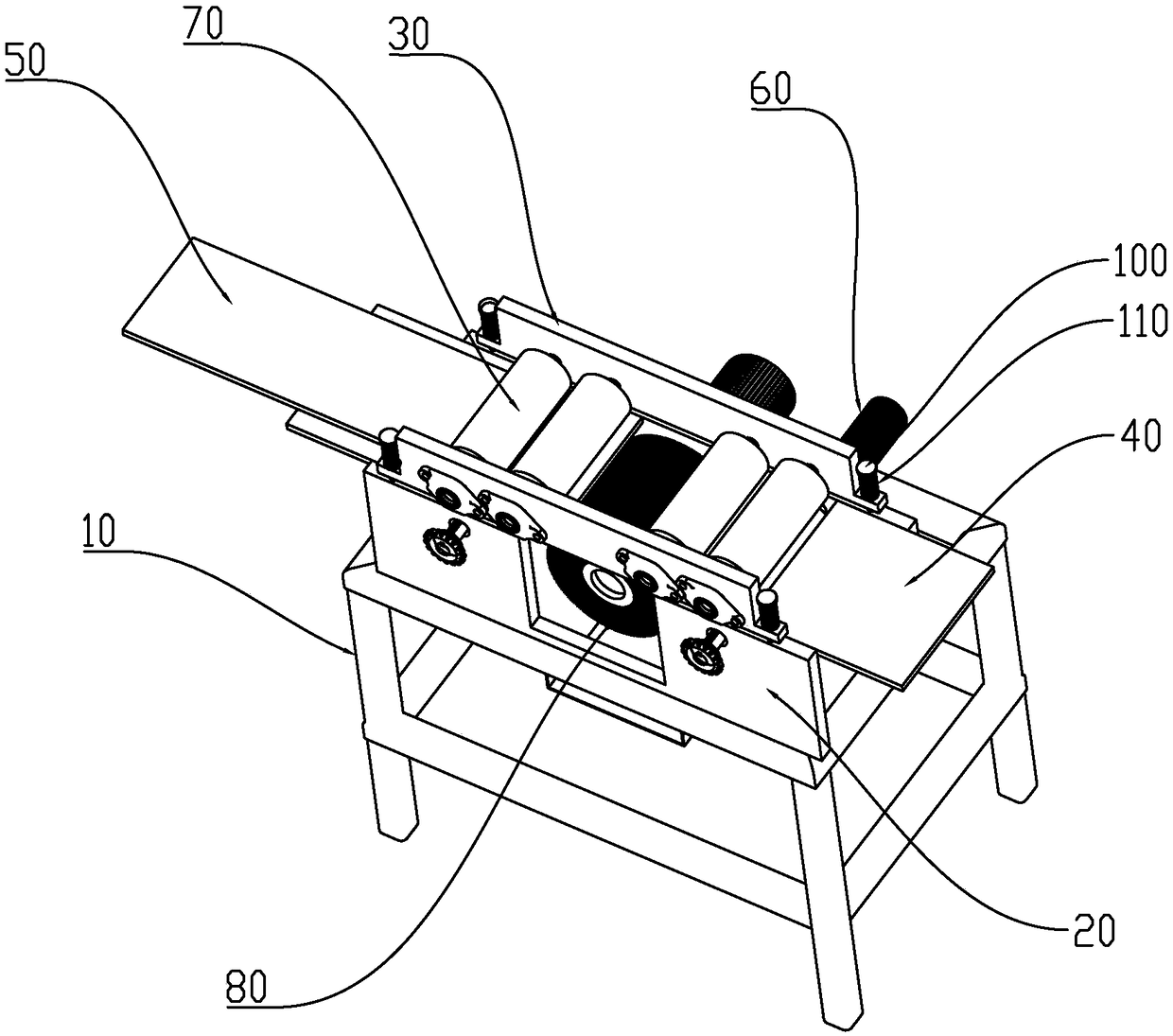

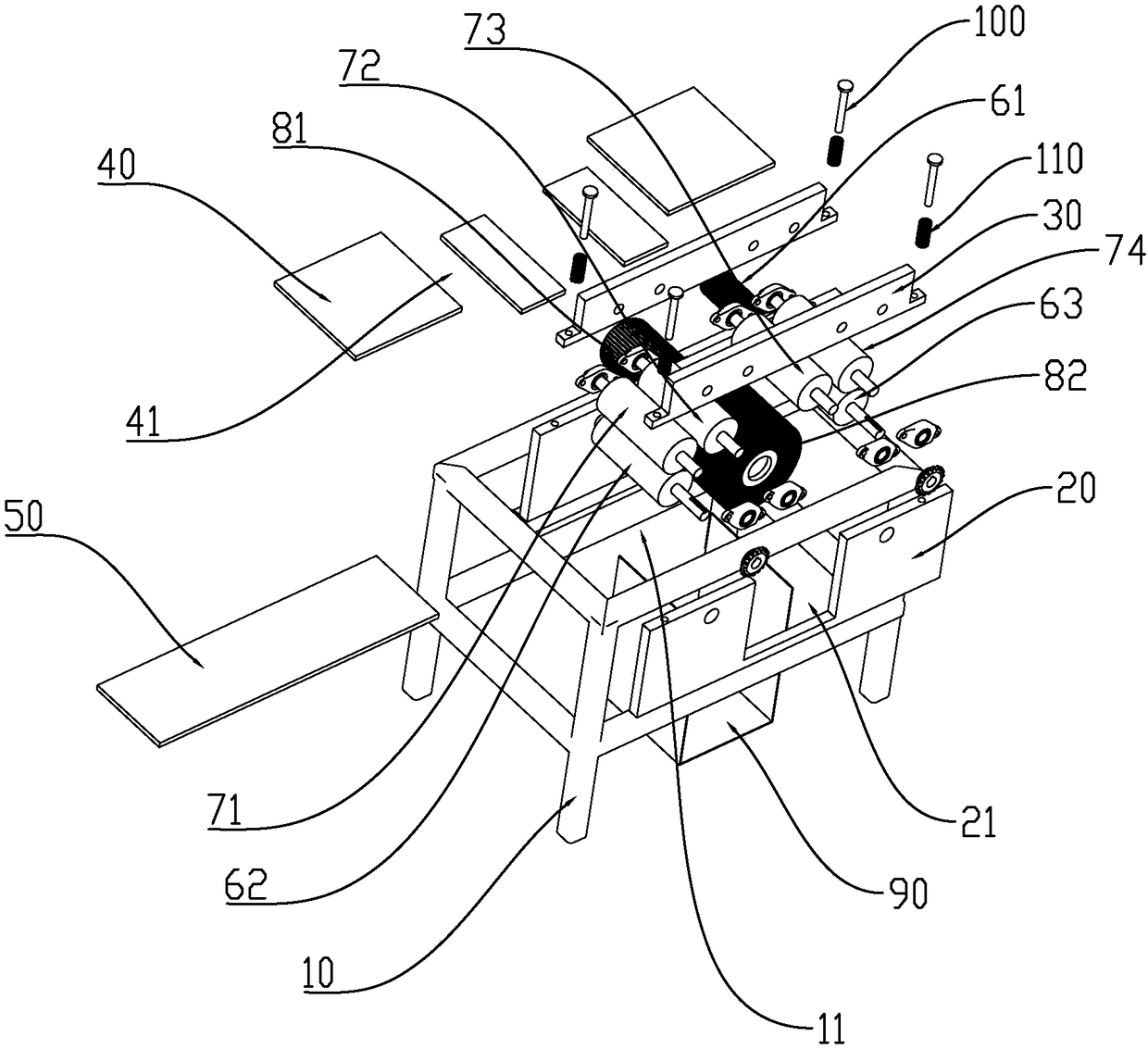

[0038] Such as Figure 1 to Figure 4 The specific example shown, where, figure 1 It is a structural diagram of a traditional water mill, which includes an abrasive belt 1, a tension spring 2, a water spray pipe 3, a conveyor belt 4, a tension roller 5, an abrasive belt driving roller 6, a height adjustment plate 7, and a conveyor belt driving roller 8, and cold water tank 9; the working principle of the traditional water mill is: the conveyor belt 4 sends the rubber plate to be ground to the bottom of the abrasive belt 1 rotating at high speed, and adjusts the gap between the abrasive belt 1 and the conveyor belt 4 through the height adjustment plate 7, In order to adapt to rubber sheets of different thicknesses, the circulation pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com