Covering piece for drilling machining

A cover sheet, water-soluble technology, applied in the field of circuit board processing, can solve the problems of high cost, lack of lubrication function, etc., to achieve the effect of improving service life, excellent lubrication effect, and improving the quality of micro-hole processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to be able to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

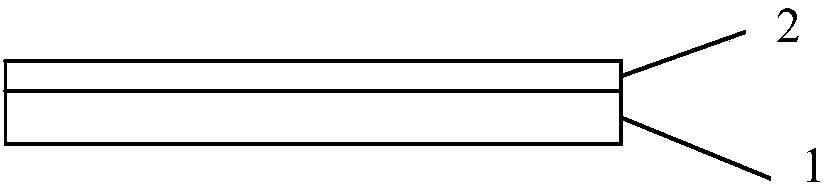

[0017] Such as figure 1 As shown, the cover sheet for drilling processing of the present invention includes a substrate layer 1, and the surface of the substrate layer 1 is coated with a water-soluble organic coating 2, and the water-soluble organic coating is polyethylene two. Alcohol organic coating.

[0018] In a preferred embodiment, the molecular weight of polyethylene glycol in the water-soluble organic coating is 1,000 to 30,000.

[0019] In a preferred embodiment, the thickness of the water-soluble organic coating is 10 μm to 200 μm, for example, 10 μm to 100 μm.

[0020] In a preferred embodiment, the substrate layer is kraft paper, white cardboard, gray cardboard or roll paper.

[0021] In a preferred embodiment, the thickness of the substrate layer is 0.05 mm to 2.0 mm, for example, 0.1 mm to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com