Special steel quenching agent

A technology of quenching agent and special steel, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of environmental pollution, waste, high cost, etc., and achieve the effect of reducing production cost, reducing the amount of addition, and using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A quenching agent for special steel, comprising the following raw materials in parts by weight: 4 parts of polyether, 1 part of sodium carbonate, 0.5 part of polyvinyl alcohol, 2 parts of boric acid, 1 part of starch, 0.1 part of triethanolamine, 3 parts of sodium benzoate, 10 parts of water share.

Embodiment 2

[0026] A quenching agent for special steel, comprising the following raw materials in parts by weight: 8 parts of polyether, 2 parts of sodium carbonate, 1 part of polyvinyl alcohol, 4 parts of boric acid, 3 parts of starch, 0.2 part of triethanolamine, 4 parts of sodium benzoate, 15 parts of water share.

Embodiment 3

[0028] A quenching agent for special steel, comprising the following raw materials in parts by weight: 14 parts of polyether, 4 parts of sodium carbonate, 1.5 parts of polyvinyl alcohol, 5 parts of boric acid, 5 parts of starch, 0.3 part of triethanolamine, 5 parts of sodium benzoate, 20 parts of water share.

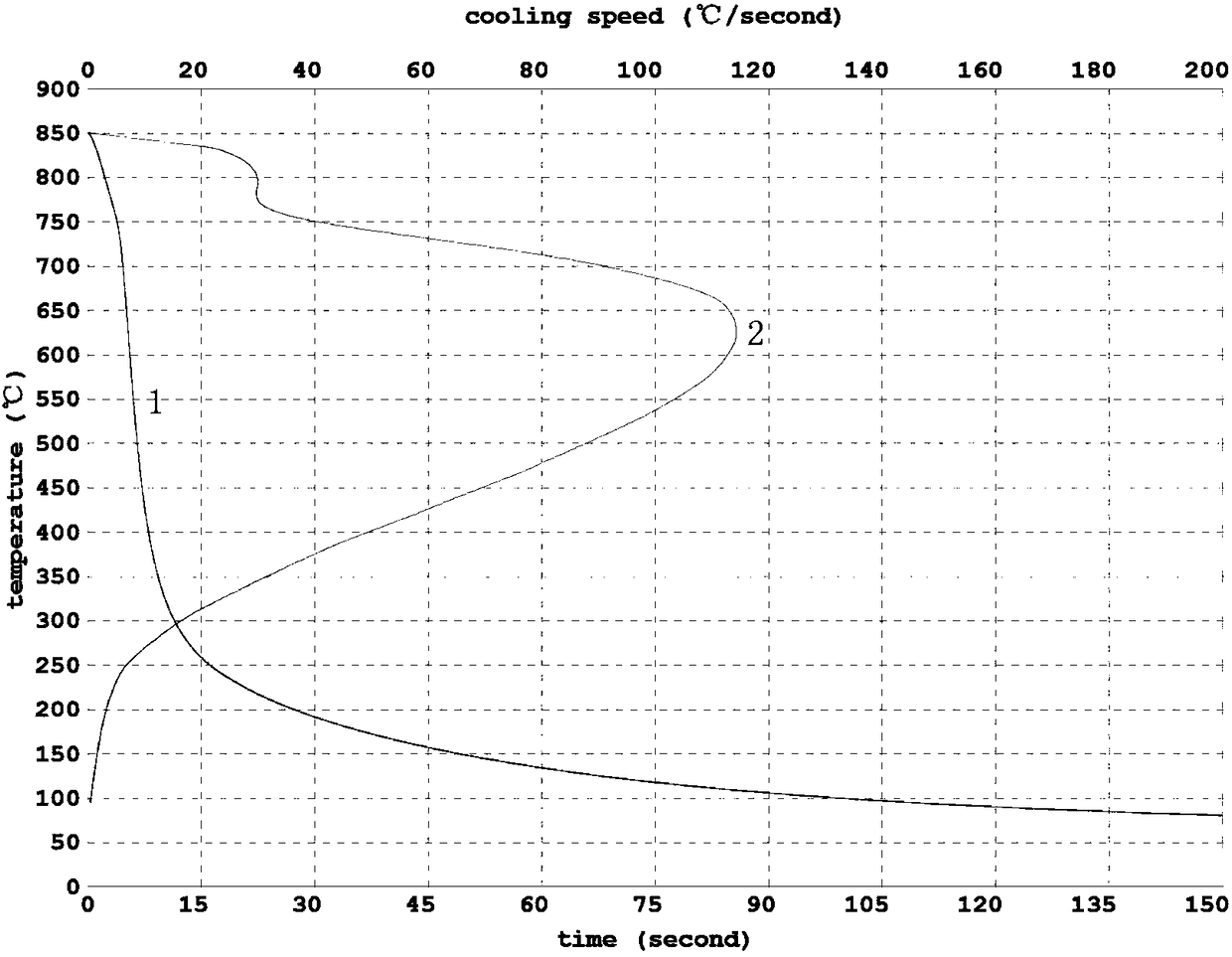

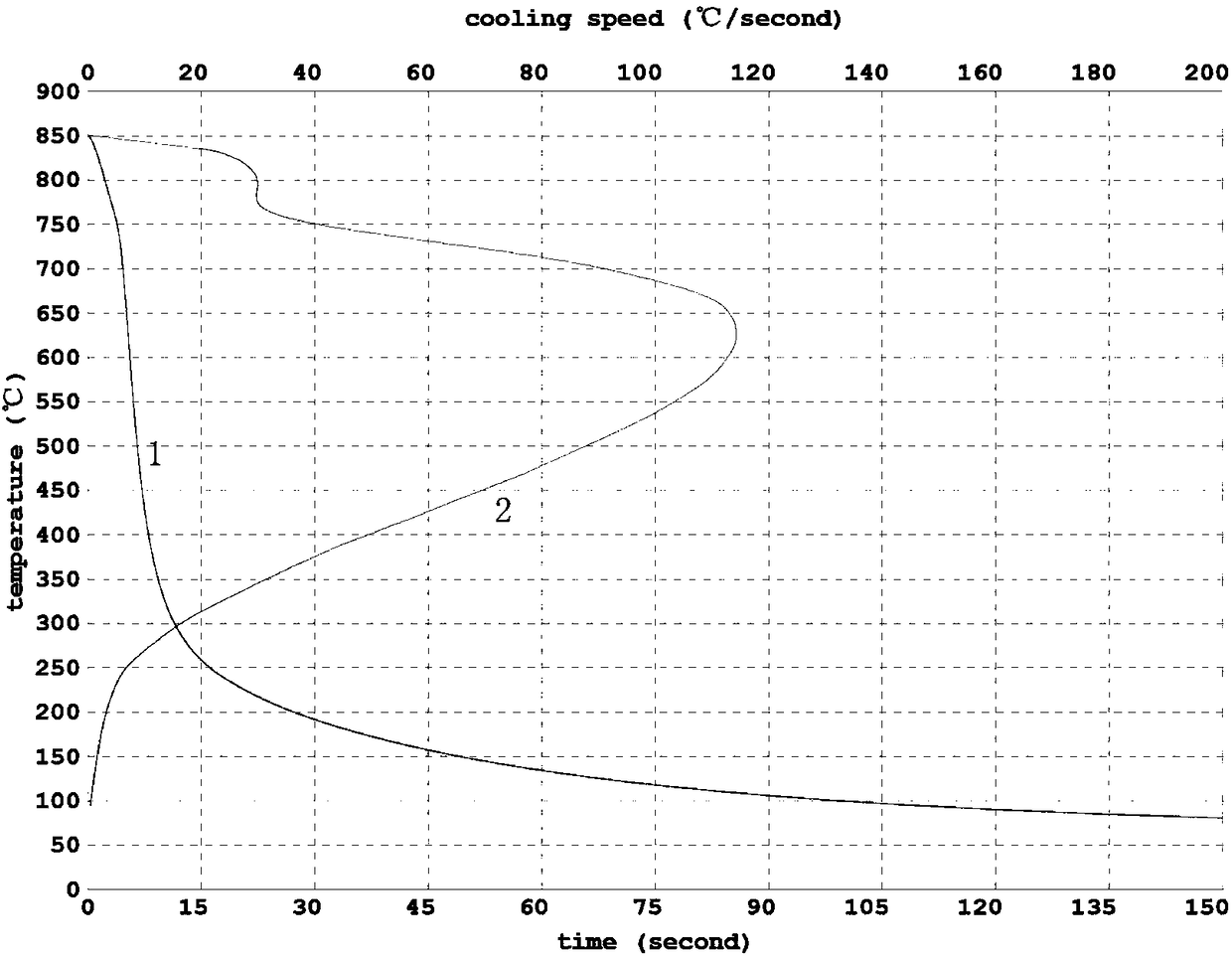

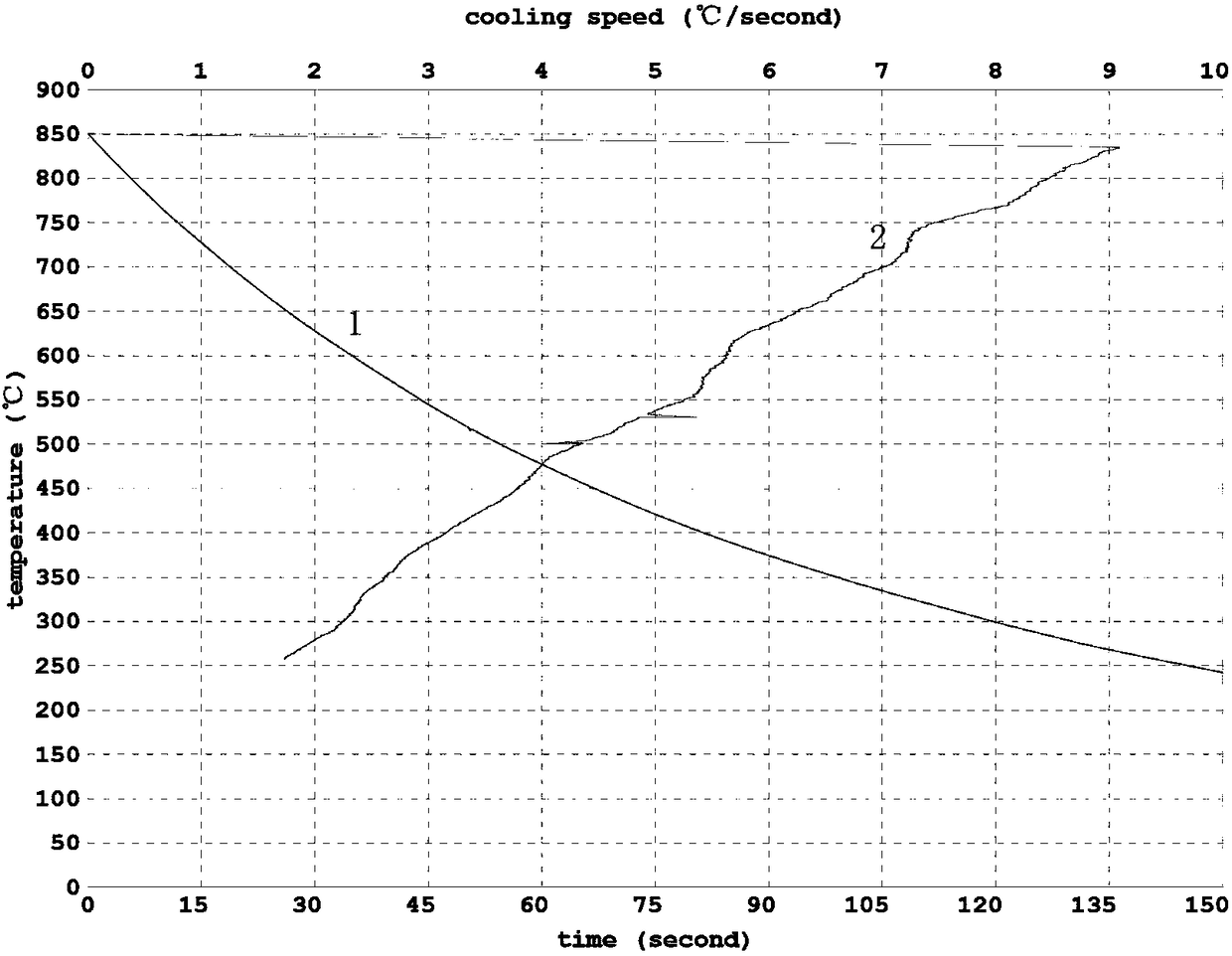

[0029] The method of using the product of the present invention: Proportion the original solution of the quenching agent with water, the ratio of the original solution to water is between 1:4 and 1:20, and the ratio can be set according to requirements. The invention belongs to the synthetic quenching agent of high molecular organic matter, with neutral PH, non-toxic, non-combustible, and the cooling speed characteristic of the aqueous solution with the ratio of 1:4-1:6 is between the wind ten spray cooling speed and the slow speed The cooling rate of quenching oil is between 30°C / s-60°C / s, and the cooling rate at 300°C is close to that of oil, which solves the problem ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap