High-lift multi-sleeve-spliced screw pump

A screw pump and field stroke technology, applied in the field of multi-casing splicing screw pumps, can solve the problems of difficult splicing of screw pump tubes, accumulation of a large amount of sludge, and easy leakage, so as to reduce the probability of sludge blockage, reduce deposition, and increase firmness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

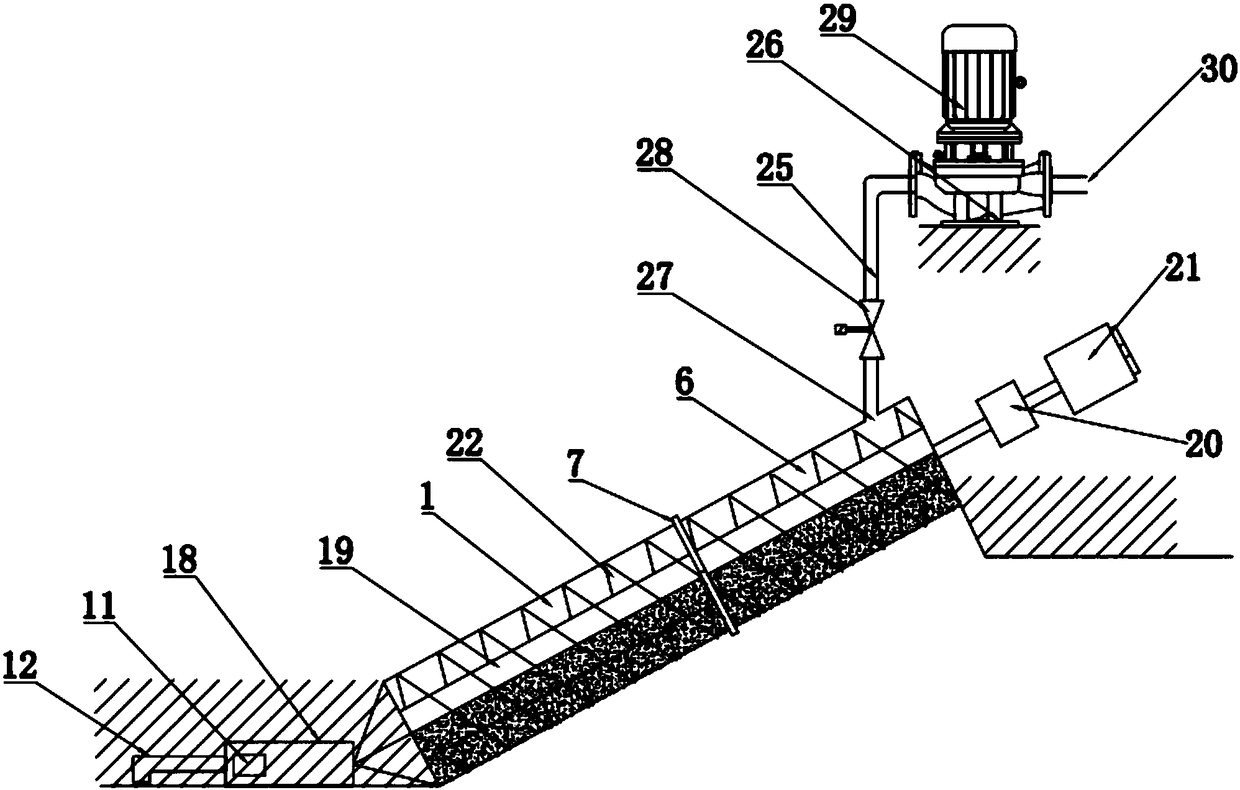

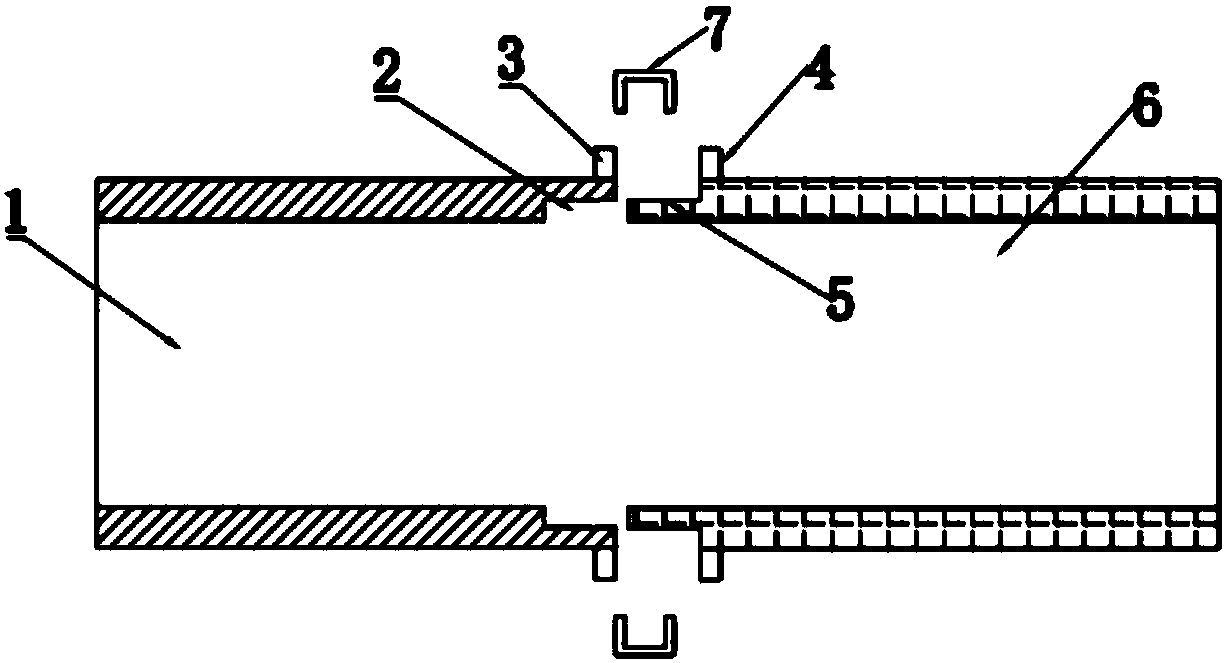

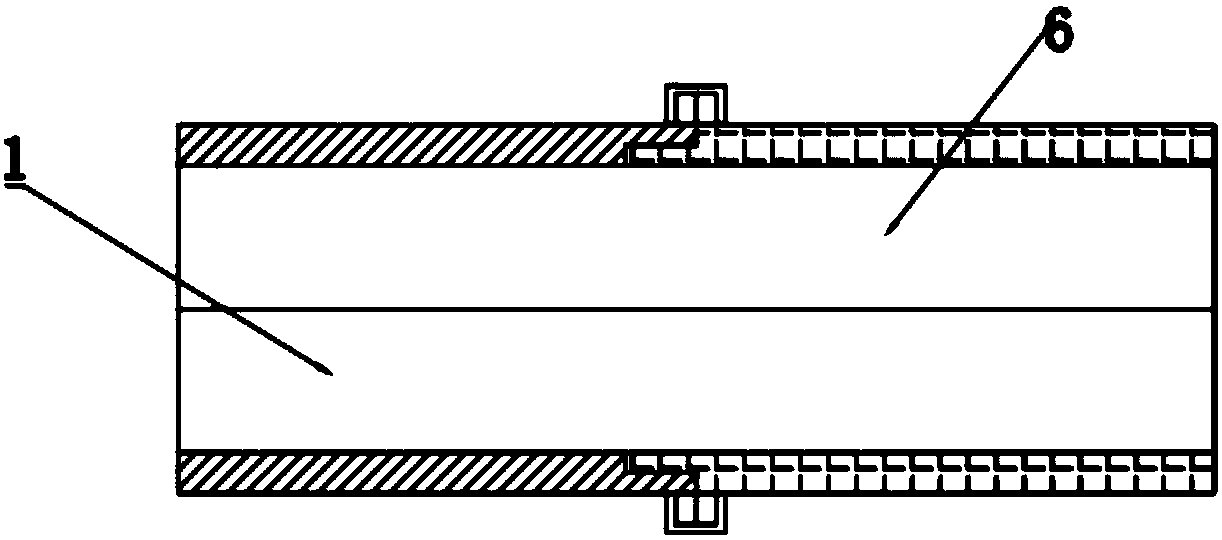

[0028] Such as figure 1 As shown, the multi-tube splicing screw pump with high field range includes left sleeve (1), right sleeve (6), screw (19), reducer (20) and motor (21). The bottom of the multi-sleeve splicing screw pump is provided with a stirring device (18), the screw (19) is provided with a screw (22), and the left sleeve (1) and the right sleeve (6) are connected by a snap ring (7) Together. When the multi-sleeve splicing screw pump with high field range requires multiple sleeves for work, the multiple left sleeves (1) and right sleeves (6) are spliced together end to end to form a sleeve of sufficient length . An air inlet (27) is provided on the upper end of the right sleeve (6). The air inlet (27) is connected to the vacuum pump (29) through the air inlet pipe (25), and the vacuum pump (29) is fixed on the base (26) On the building, there is an air outlet (30) on the right side of the vacuum pump (29). Because the vacuum pump (29) pumps air in the casing, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com