A waveguide low-pass harmonic suppressor with dimples

A harmonic suppressor and waveguide technology, applied in waveguide-type devices, circuits, electrical components, etc., can solve the problems of reducing the power capacity of the filter and deepening the depth of harmonic suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

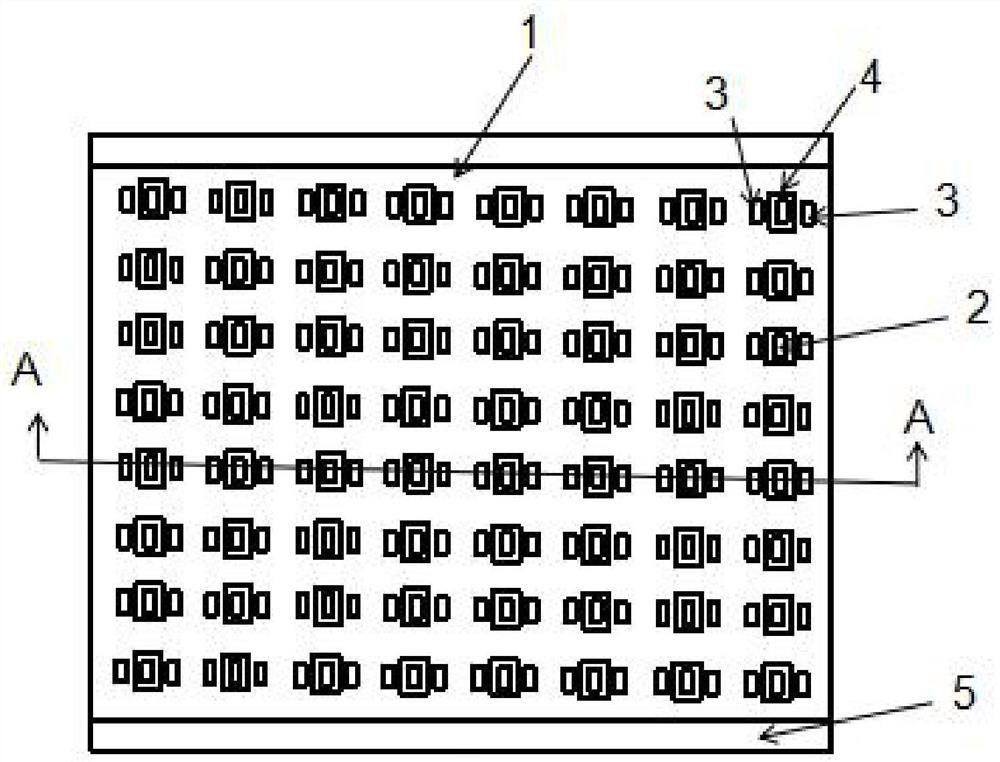

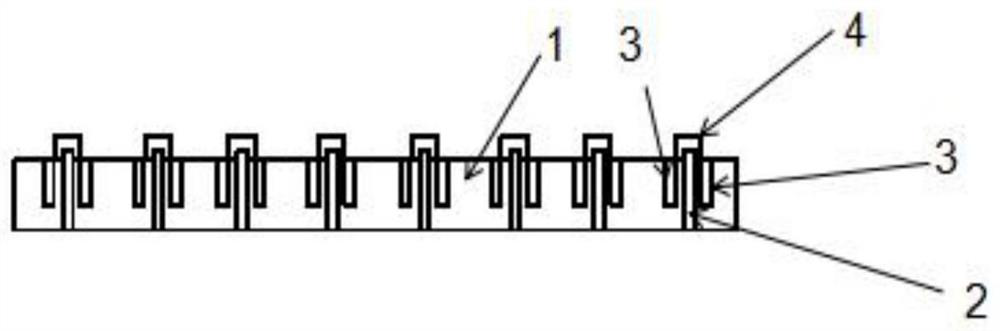

[0016] Such as figure 1 , figure 2 As shown, a waveguide low-pass harmonic suppressor with pits includes a resonant cavity 1, an input and output waveguide 5, and 8 horizontal rows and 8 vertical rows of metal pillars A2 connected to the resonant cavity 1 only at the bottom. The waveguide low-pass harmonic suppressor with pits also includes a metal post B3 corresponding to each metal post A2 and connected to the resonant cavity 1 only at the top; the cross section of the metal post B3 is the same as the cross section of the metal post A2 Sections are different.

[0017] The metal pillars A2 are rectangular, and each metal pillar A2 corresponds to two rectangular metal pillars B3; each metal pillar A2 is embedded between the two corresponding rectangular metal pillars B3. A metal pit 4 is arranged on the top of the resonant cavity 1 corresponding to each of the metal posts A2; each metal post A2 is embedded in the corresponding metal pit 4.

Embodiment 2

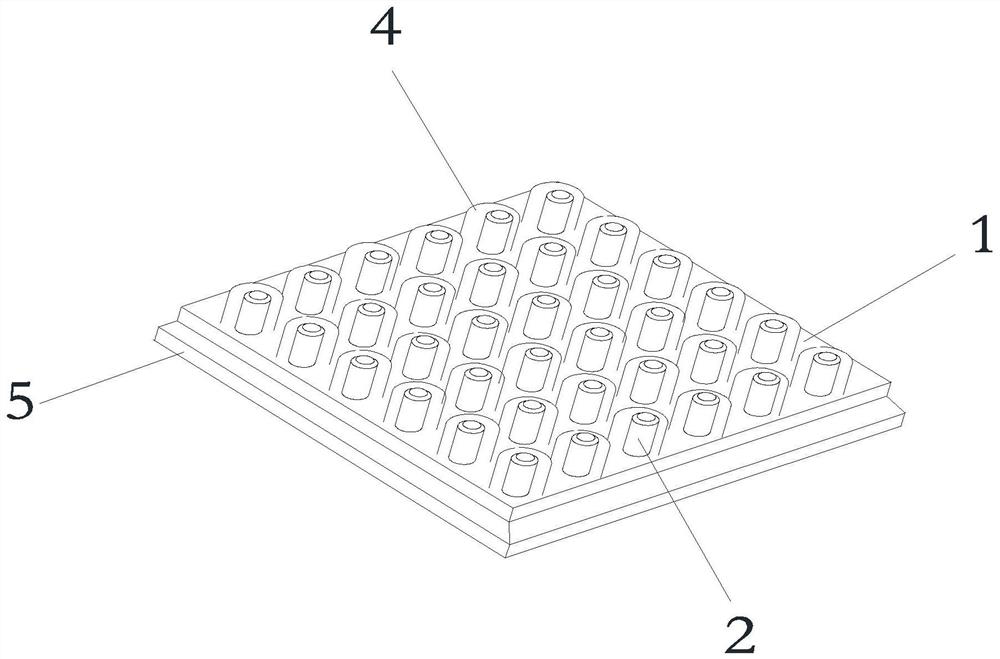

[0019] Such as image 3 As shown, the difference between this implementation example and implementation example 1 is that each of the metal pillars A and each metal pit is a cylinder. No metal post B is provided on top of the cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com