Fixed-length welding method of connection port of blower shell

A welding method and connection port technology, applied in the field of integrated stoves, can solve the problems of high manufacturing cost, influence on smoke exhaust effect, and low manufacturing efficiency, and achieve the effects of low manufacturing cost, improved smoke exhaust effect, and high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

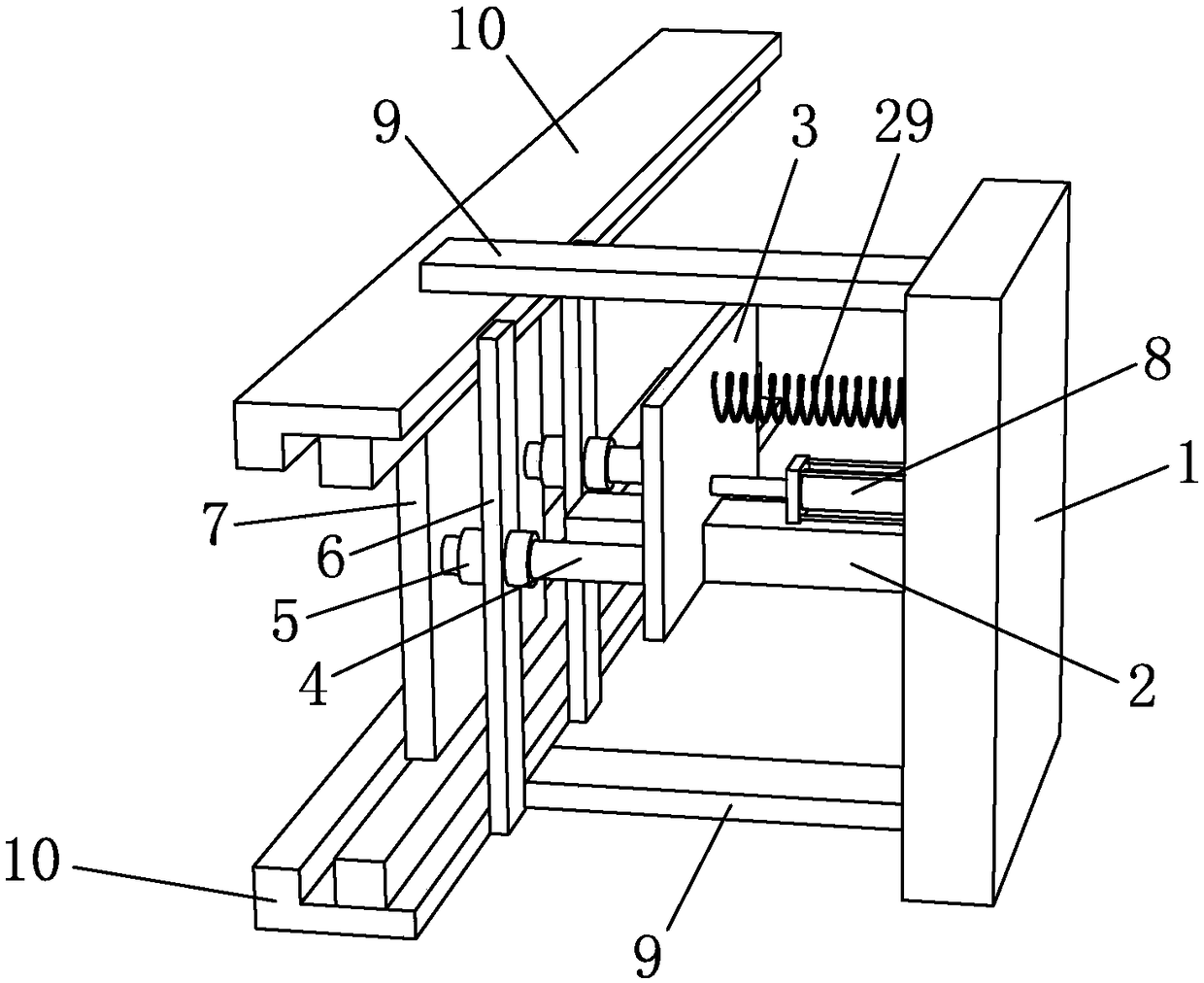

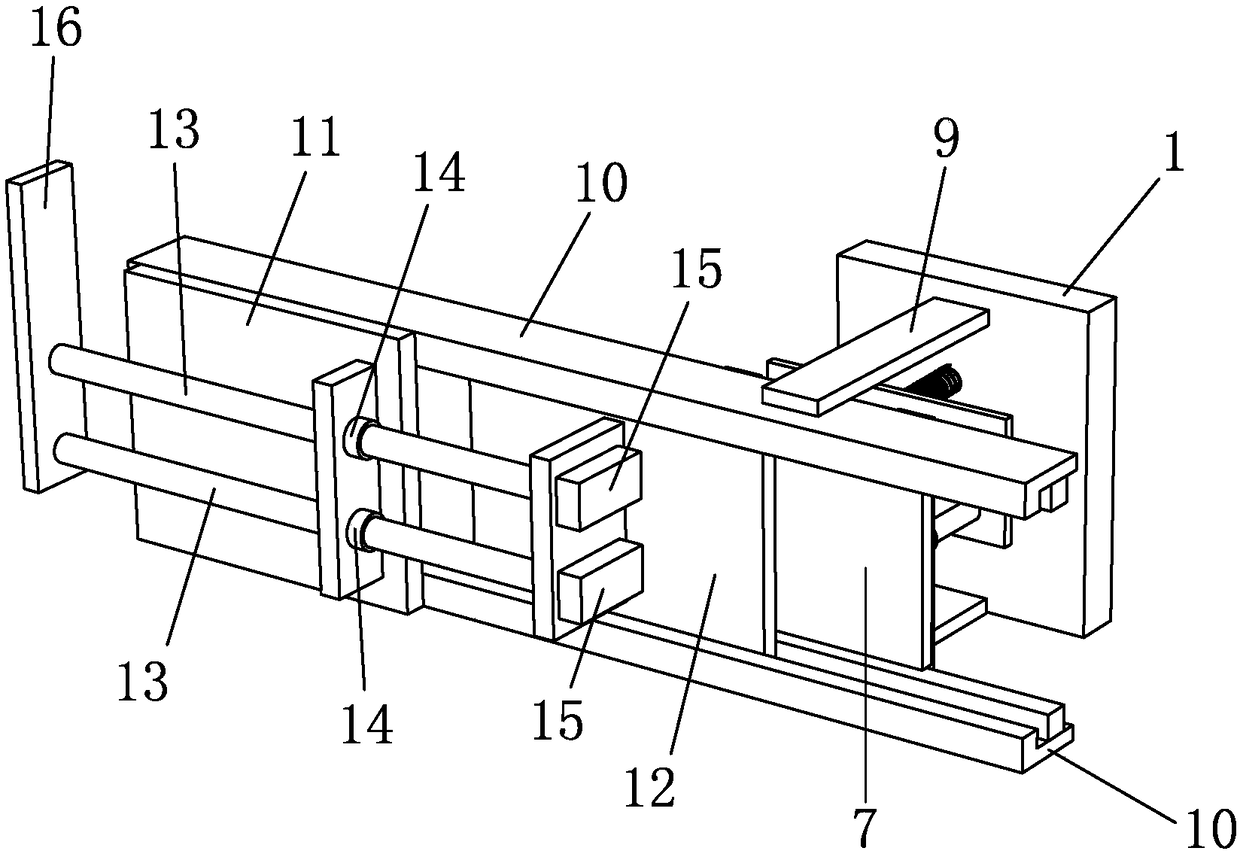

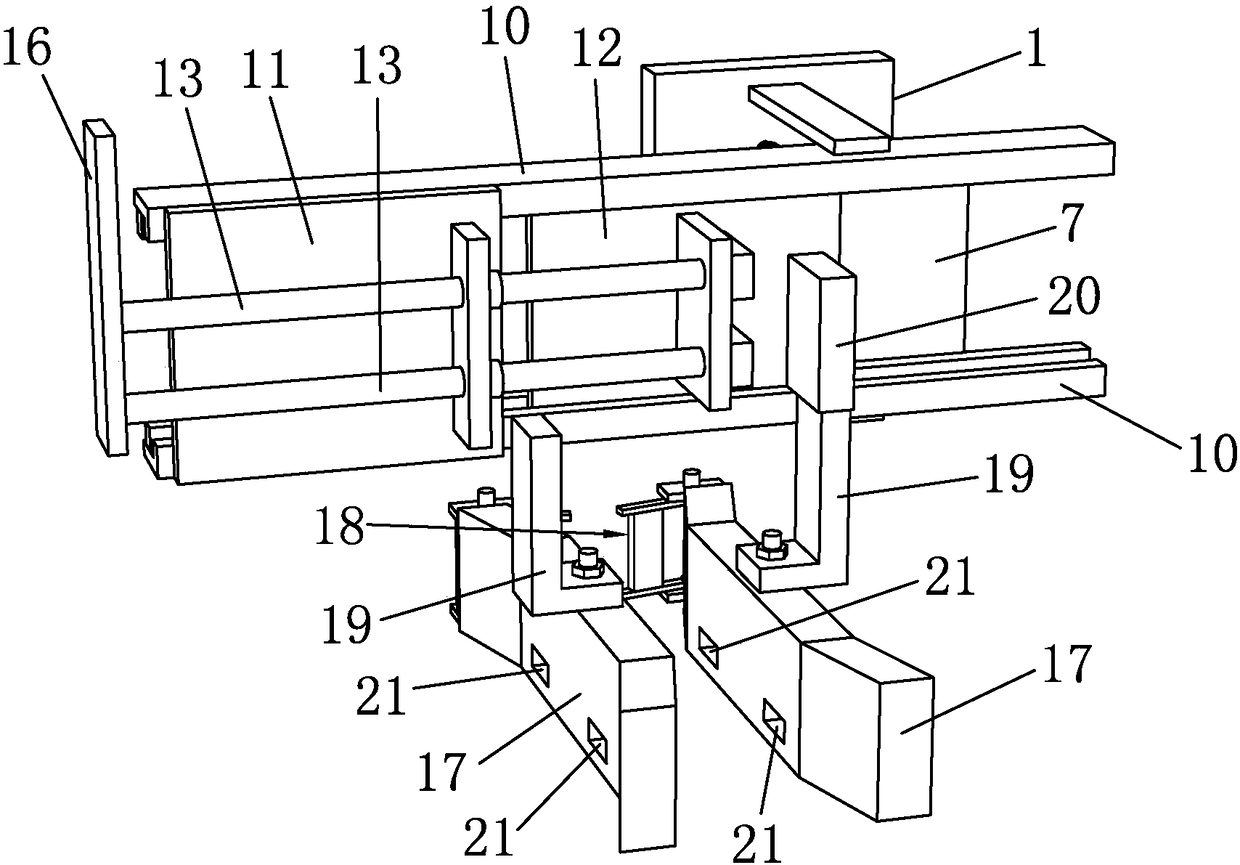

[0032] Such as Figure 1 to Figure 8 As shown, it is a fixed-length welding method for the connection port of the fan casing according to the present invention, which includes the following steps:

[0033] a. Install the horizontal push device: first weld the support plate 2 on the side of the horizontal push base 1, then weld two guide rods 4 symmetrically on the side of the connecting plate 3, and weld the first fixed plate 6 on the guide sleeve 5 at the same time, and then Guide sleeve 5 moves on guide bar 4. Then weld the flat push plate 7 at the end of the guide rod 4, and then slide the connecting plate 3 onto the support plate 2. Then, the hydraulic cylinder 8 is fixedly connected to the side of the flat push base 1, and then the hydraulic cylinder 8 is fixedly connected to the connecting plate 3. Then weld two second fixing plates 9 on the side of the push base 1 , then weld the second fixing plates 9 to the guide rail 10 , and then weld the first fixing plate 6 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com