Water stopper

A technology of water stopper and rod body, applied in the field of water stopper, can solve problems such as deformation and leakage points, and achieve the effects of extending the moving path, easy operation and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

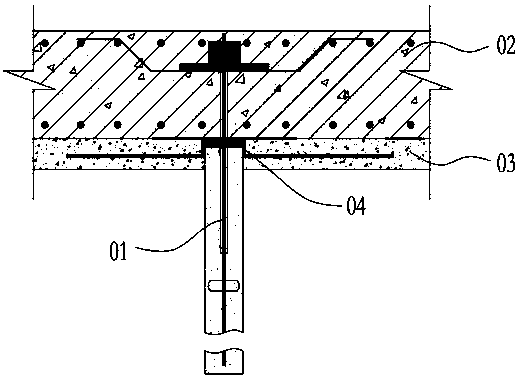

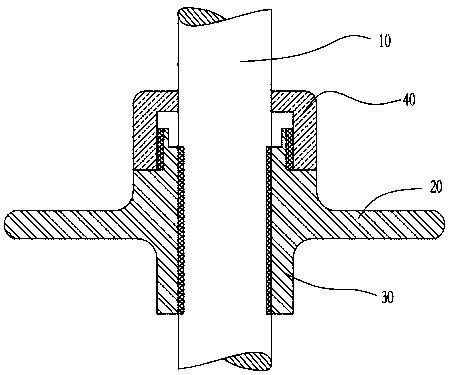

[0022] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated: please refer to figure 2 , a water stopper, used for anti-seepage at the joint between the bolt body 10 and the concrete bottom plate. The water stopper includes a plate body 20 , a cylinder body 30 passing through the plate body 20 , and a cover body 40 covering one end of the cylinder body 30 .

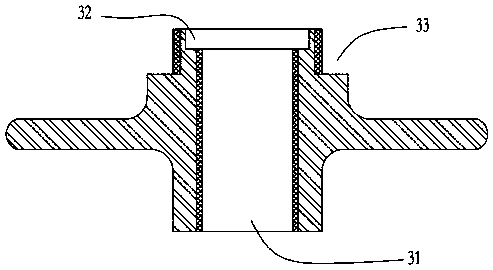

[0023] Please refer to image 3 with Figure 4 , the cylinder 30 is provided with a first through hole 31 for the anchor rod body 10 to pass through, and the inner wall of the first through hole 31 is provided with a first annular groove 32, and the cavity surrounded by the first annular groove 32 and the anchor rod body 10 Filled with sealant.

[0024] Preferably, the first annular groove 32 is disposed on the cylinder body 30 close to the top of one end of the cover 40 , and the cover 40 is disposed on the first annular groove 32 . The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com