Method for evaluating road technical condition based on non-destructive testing technique

A technology for non-destructive testing of technical conditions, applied in radio wave measurement systems, radio wave reflection/re-radiation, measurement devices, etc., can solve the problems of long single operation time, stuck drill, affecting driving safety, etc., to achieve the degree of equipment automation High, meet the requirements of precision, and improve the effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The described embodiments are only used to illustrate the technical solutions of the present invention, and are not intended to limit the present invention.

[0022] First use the intelligent road surface damage automatic collection system to collect road surface images, refer to figure 1 shown. Step 1, perform distance calibration and distance correction; Step 2, image acquisition; Step 3, compress and store the image; Step 4, analyze and classify and mark the collected images, and record the test location; Step 5, export data.

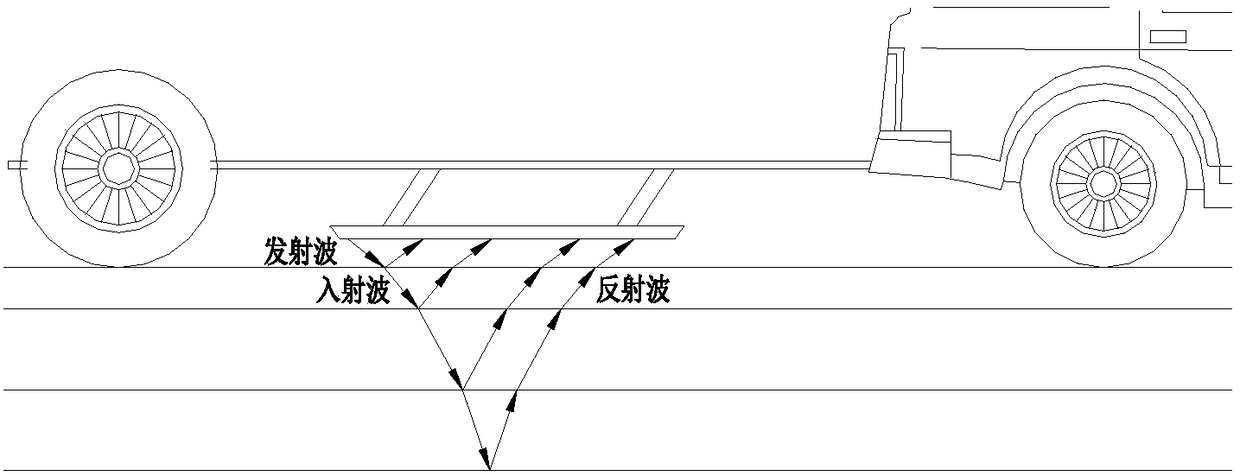

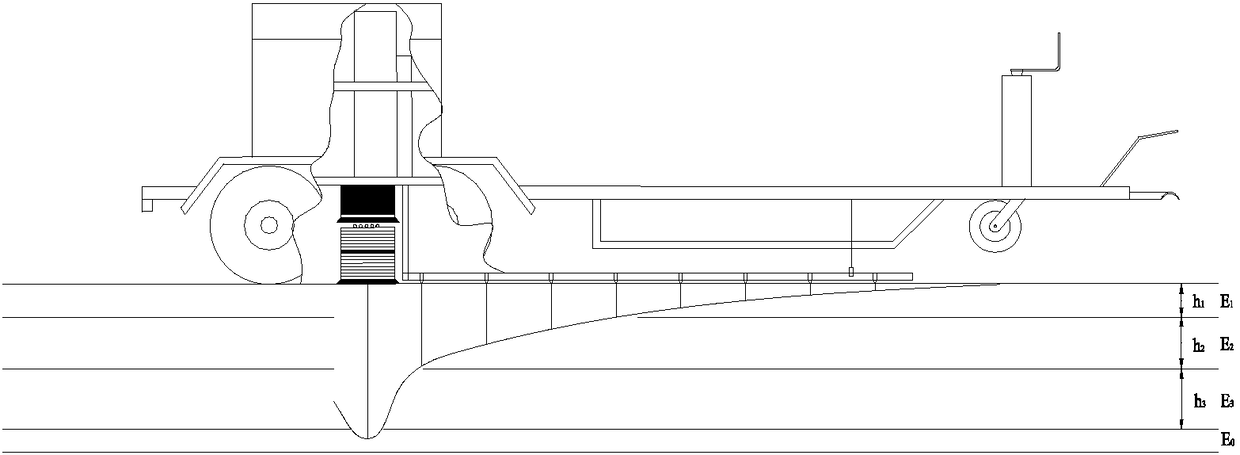

[0023] Then use 3D ground penetrating radar to collect data inside the pavement structure, refer to figure 2 shown. Step 1, radar rangefinder calibration; Step 2, radar basic parameter setting; Step 3, radar equipment automatic detection; Step 4, data acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com