A method for detecting wafer ups and downs and a grinding device

A detection method, wafer technology, applied in the direction of measuring device, optical device, grinding feed movement, etc., to achieve the effect of preventing the number of processes from increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

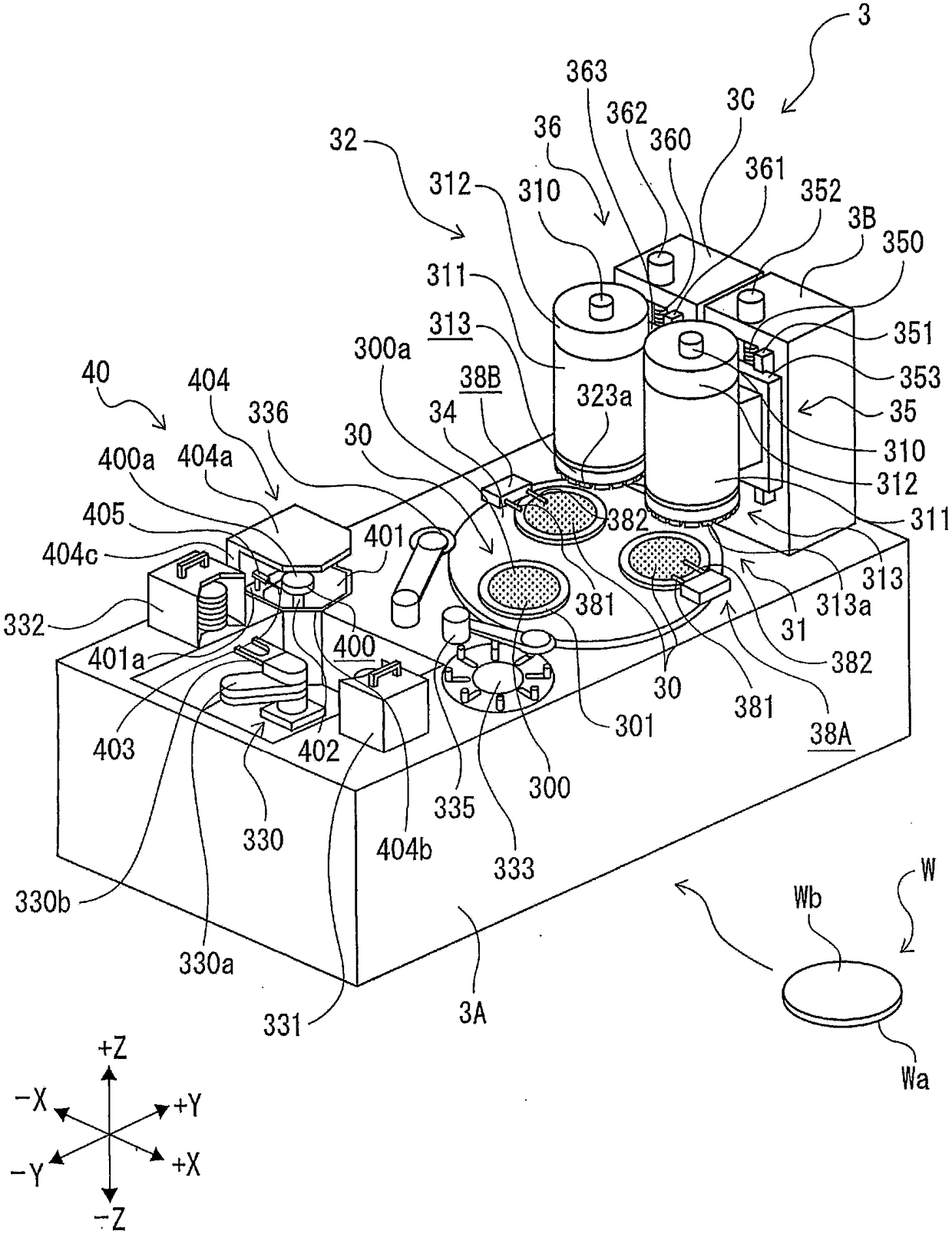

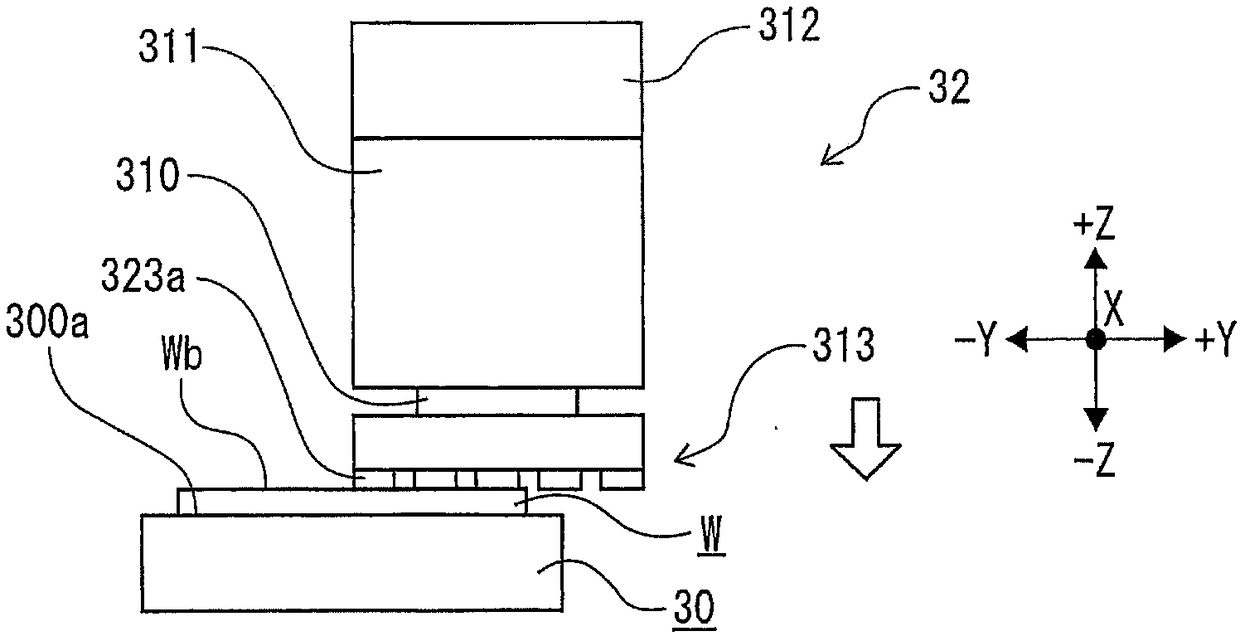

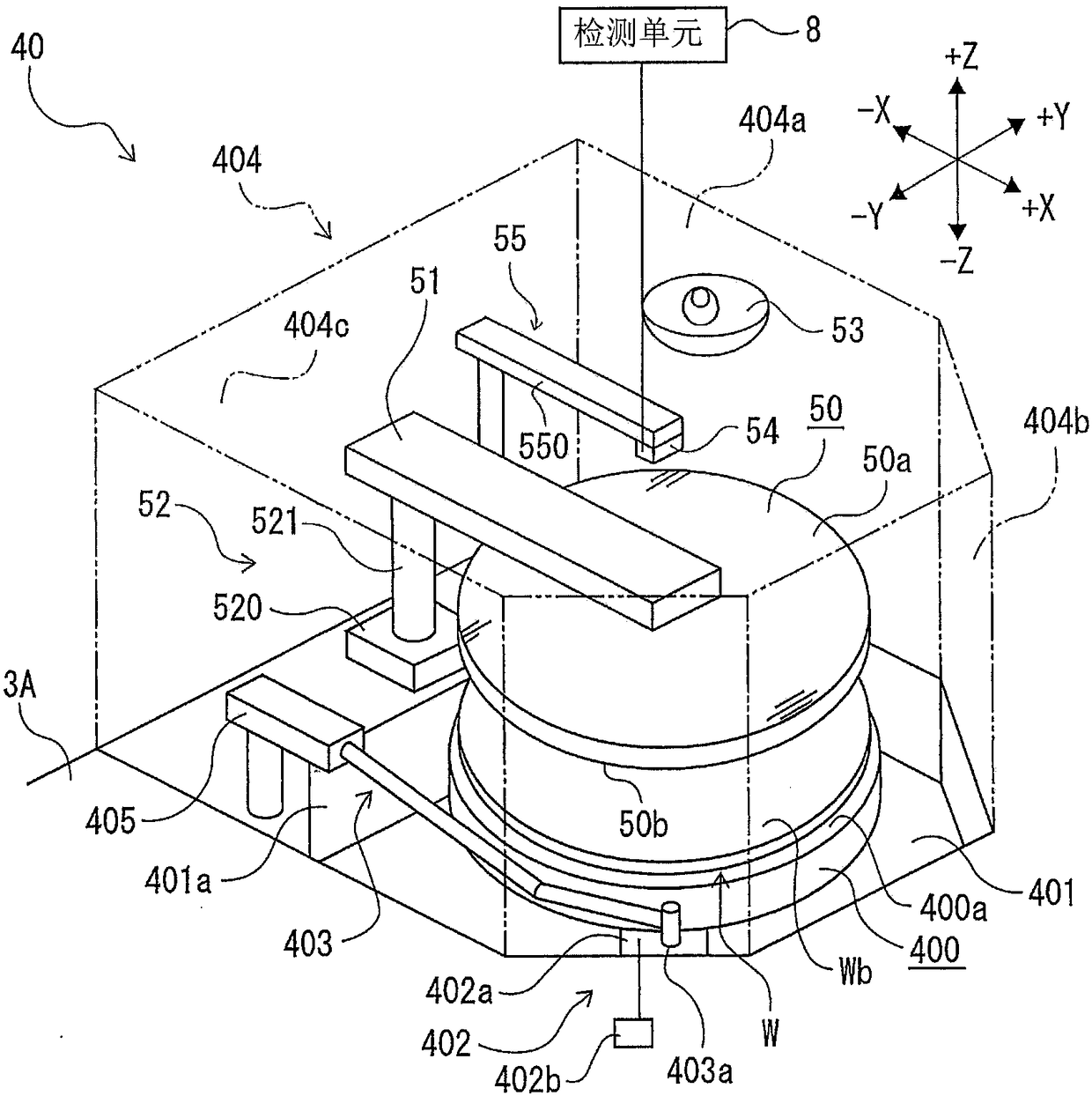

[0019] figure 1 The shown grinding device 3 is a device that performs grinding processing on the wafer W sucked and held by the chuck table 30 . Thinned by grinding figure 1 The illustrated wafer W is, for example, a circular semiconductor wafer made of silicon, and on the front surface Wa of the wafer W, a plurality of devices are formed in grid-like regions partitioned by dividing lines. The front Wa is protected by, for example, a not-shown protective tape. The back surface Wb of the wafer W is a ground surface to be ground.

[0020] The front side (the −Y direction side) on the base 3A of the grinding apparatus 3 is an area where the wafer W is attached to and detached from the chuck table 30 by the robot 330 capable of transferring the wafer W. The rear side (+Y direction side) on the susceptor 3A is held on the chuck table 30 by a rough grinding unit 31 for rough grinding the wafer W or a finish grinding unit 32 for finishing the wafer W. Grinding area on wafer W.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com