Resonance compensating circuit and method of piezoelectric assembly

A compensation circuit, series resonant circuit technology, applied in electrical components, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. work efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

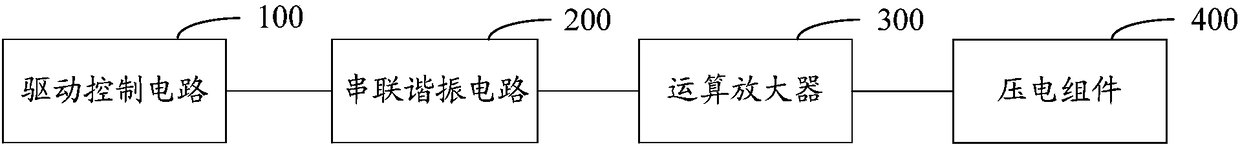

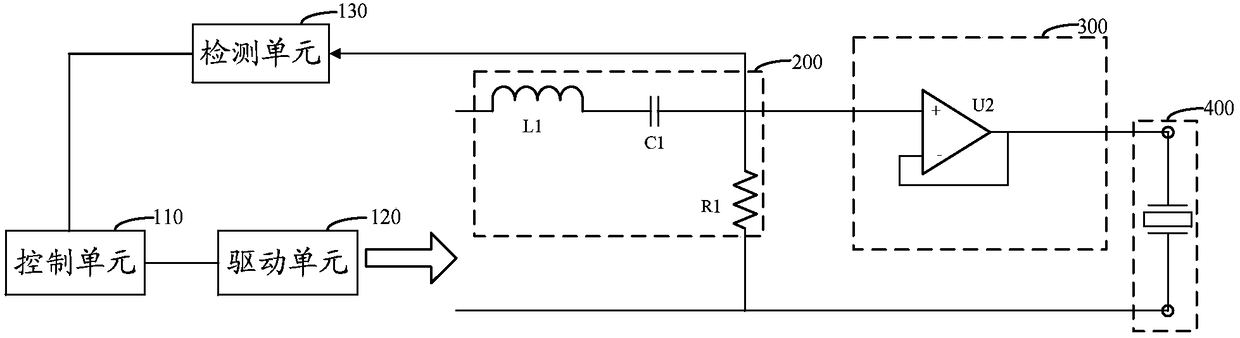

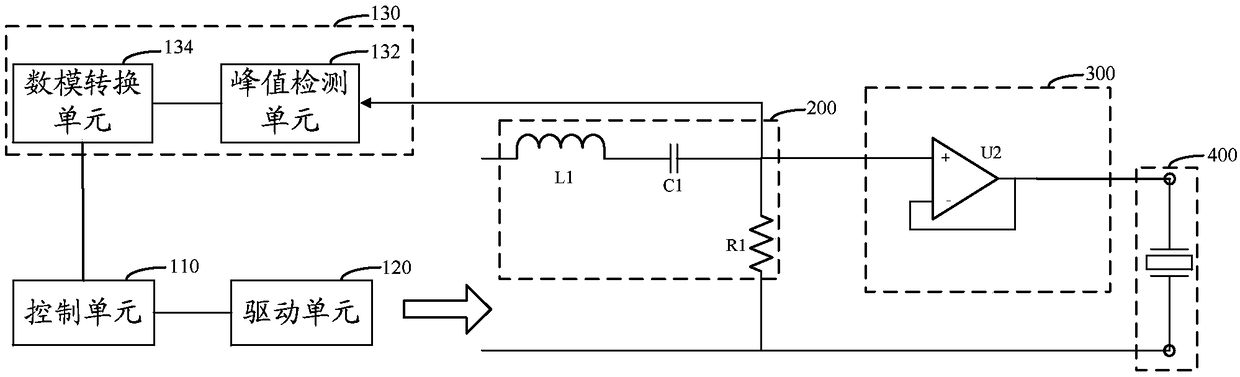

[0038] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

[0039] The piezoelectric element resonance compensation circuit and method provided in the present application can be applied in the environment of metal touch application. In the metal touch environment, when the piezoelectric component sends a clock signal and the finger touches the metal surface, the sending clock signal includes periodic sine wave, square wave or triangle wave, etc., and the received signal will absorb part of the energy due to the finger. However, the amplitude of the output clock signal will decrease. The resonance compensation circuit and method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com