Quick-mounting-type activated carbon filter

An activated carbon filter and quick-loading technology, applied in the fields of dispersed particle filtration, transportation and packaging, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance and troublesome replacement, and achieve the effect of convenient maintenance and replacement of activated carbon particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

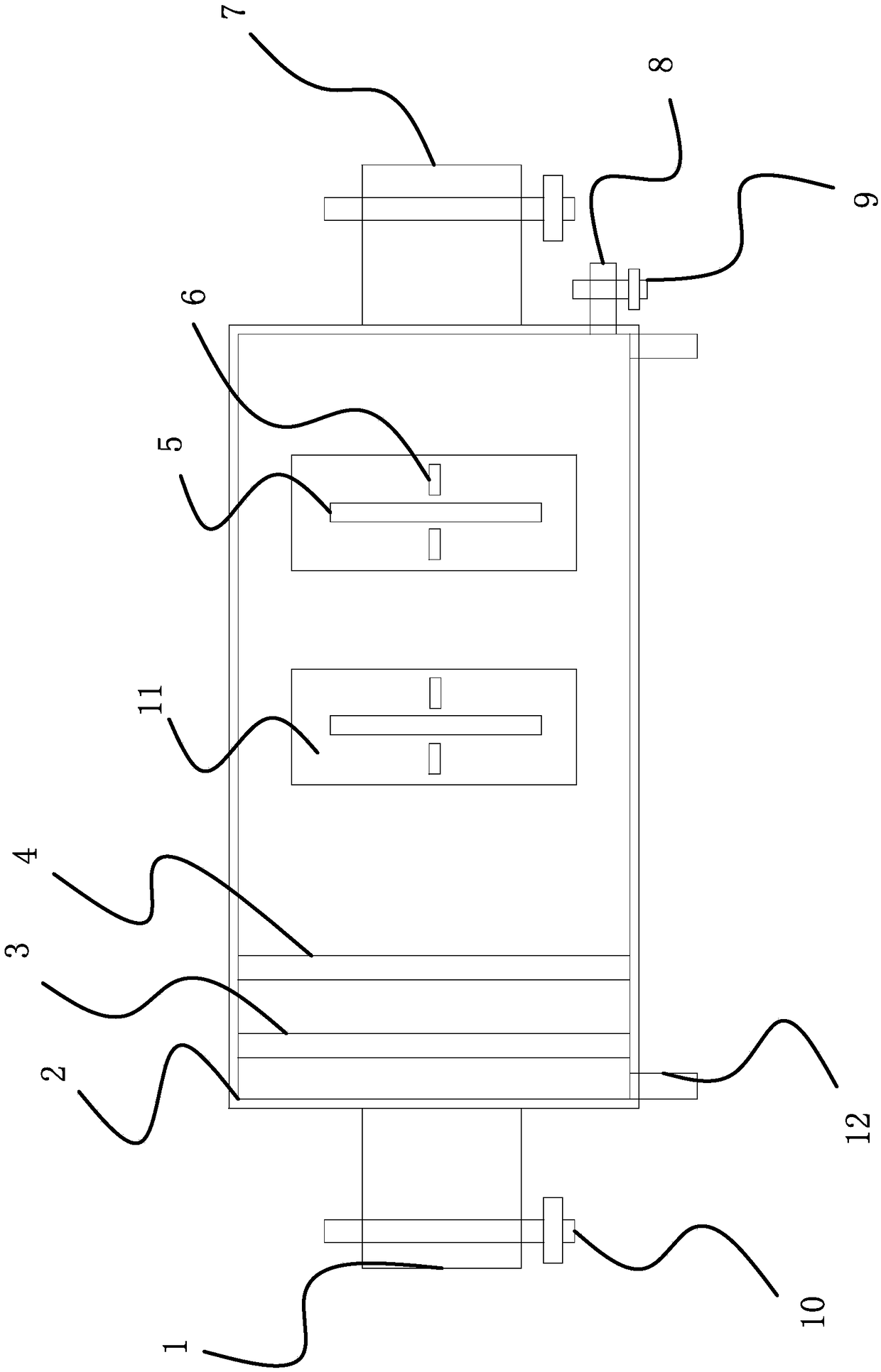

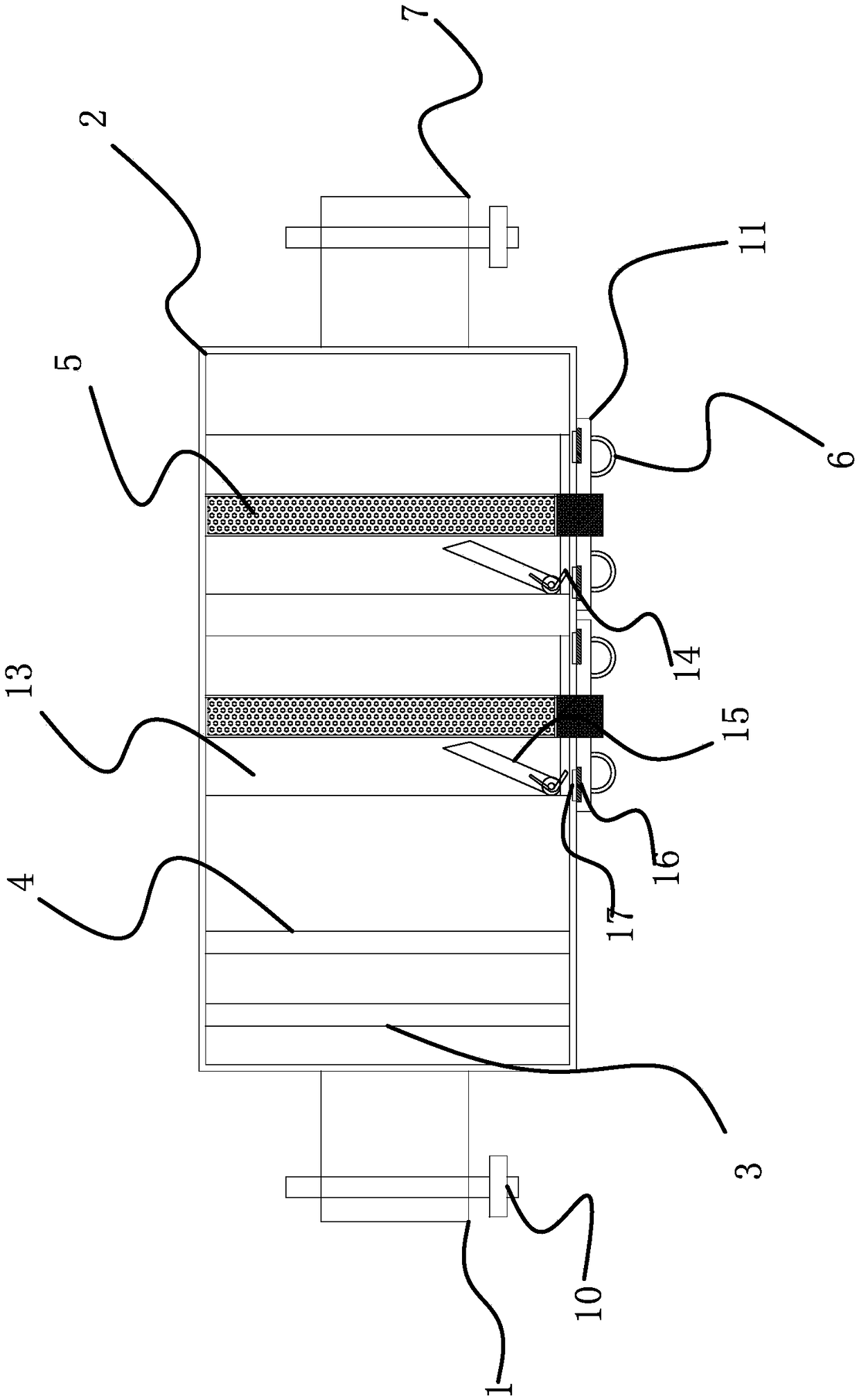

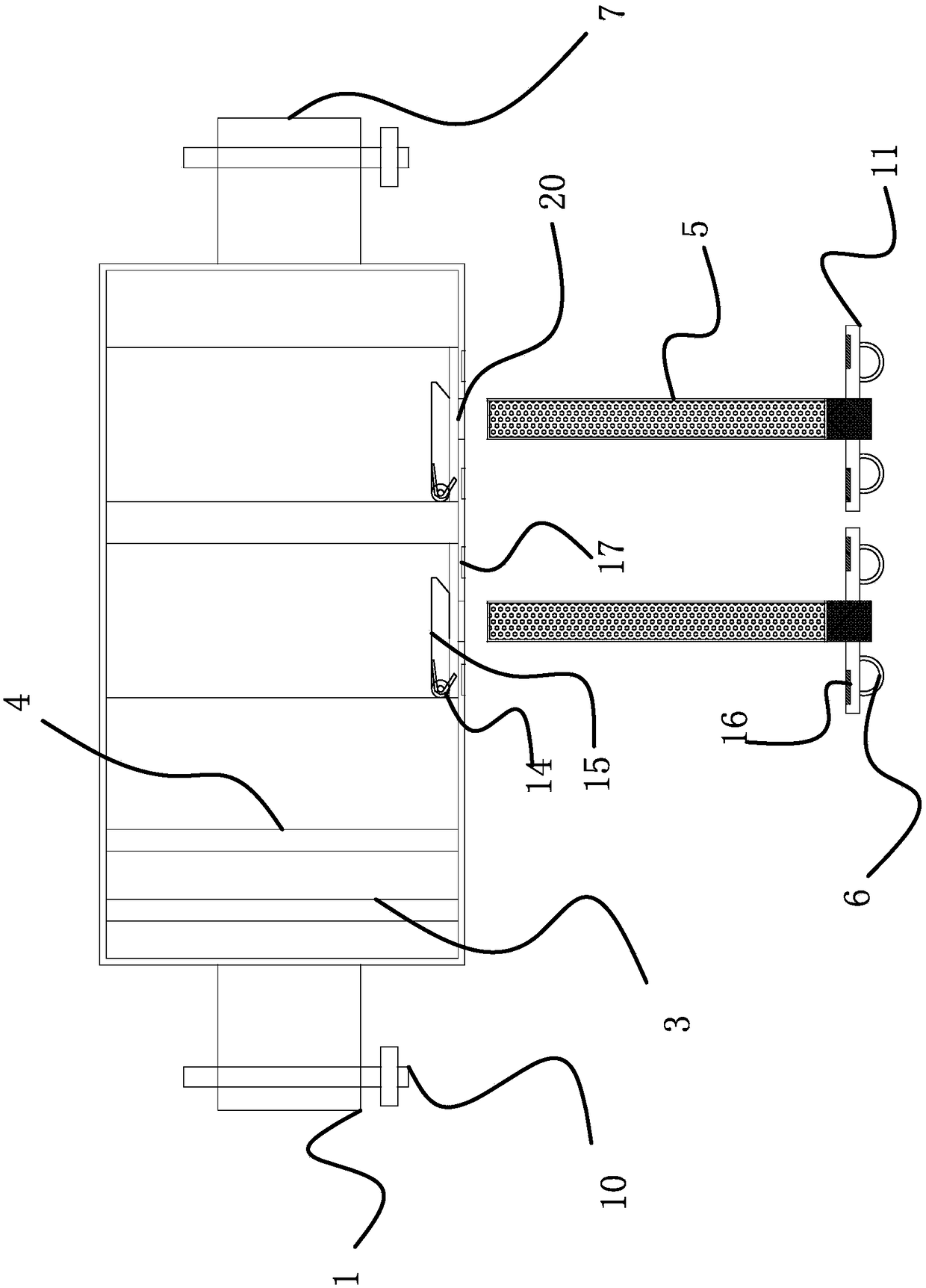

[0027] like Figure 1-6 As shown, the technical solution of the present invention is a quick-loading activated carbon filter, which includes a square cylinder 2, an air inlet 1, an air outlet 7, some carbon plates 5 filled with activated carbon particles, the first basalt The fiber felt 3 and the second basalt fiber felt 4 are characterized in that the bottom of the cylinder 2 is provided with a sewage outlet 8 and connected with a one-way valve 9, and the air inlet 1 and the air outlet 7 are arranged at both ends of the cylinder 2 , the air inlet 1 and the air outlet 7 are all provided with a check valve 10, the first basalt fiber felt 3 and the second basalt fiber felt 4 are installed in the cylinder 2 near the air inlet 1 and their edges are in line with the cylinder The inner wall of the body 2 is attached, and there are two supporting frames 13 inside the cylinder body 2. The surroundings of the supporting frame 13 are adjacent to and fixed against the inner wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com