Immobilizing method for micro-molecular ligand containing secondary amine and/or tertiary amine groups

A technology of small molecule ligands and tertiary amine groups, applied in chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve problems such as weak interactions and difficult fixation, and achieve Fixing method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

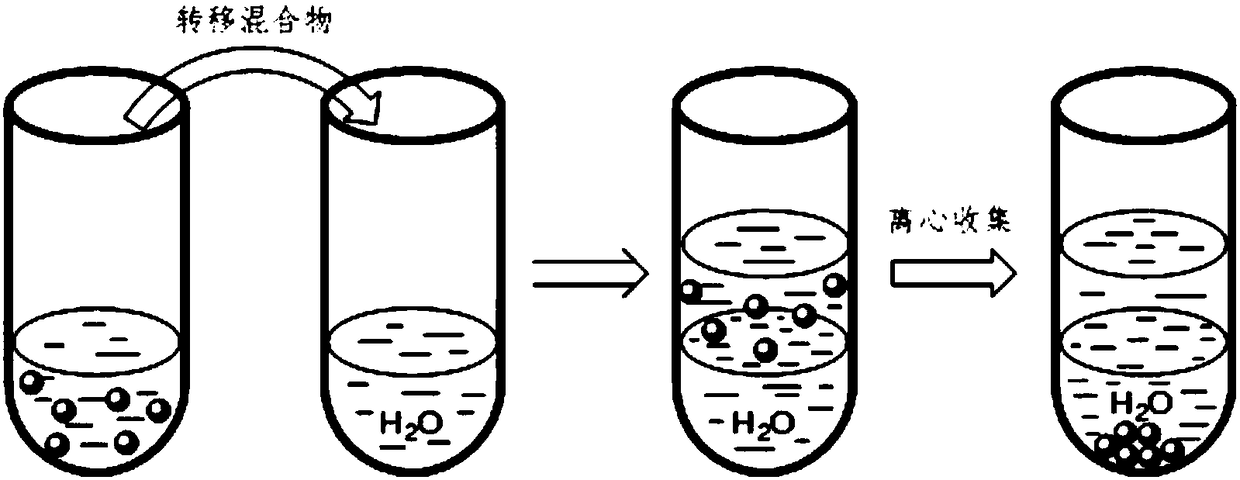

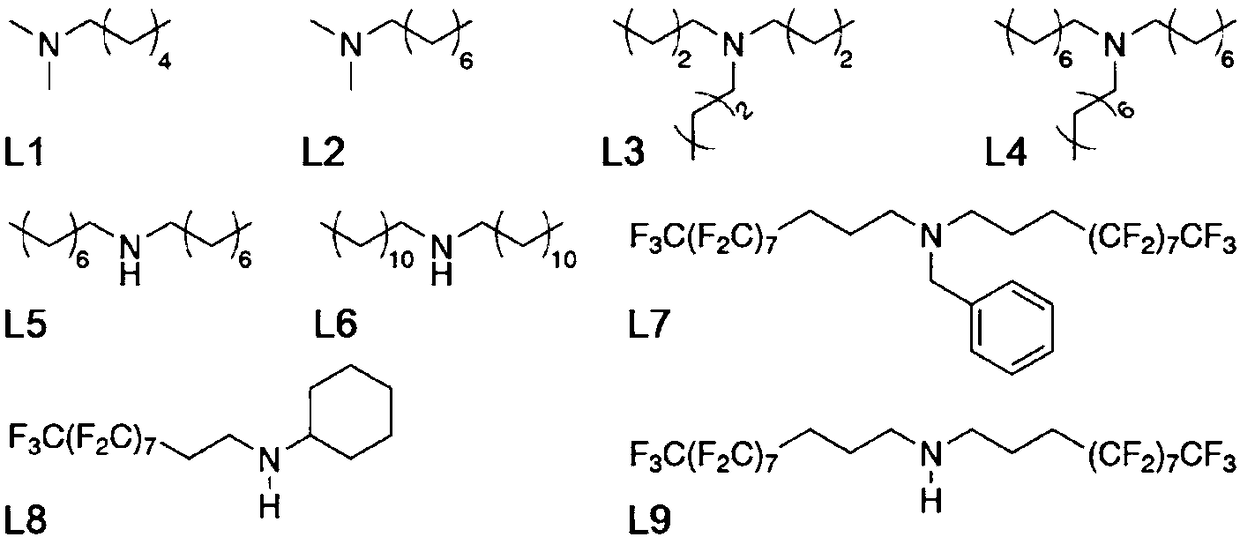

[0025] Weigh 39 mg small molecule ligand L1 (see attached figure 2 ) into a reaction flask filled with 6mL of ethyl acetate, vigorously stirred until completely dissolved, and 300 mg of titanium dioxide-loaded ruthenium catalyst was added to the above reaction flask. After maintaining stirring for 2 hours, the mixture was transferred to a centrifuge tube containing 6 mL of water. Centrifuge at 3000 rpm for 20 minutes, collect the centrifuged solid and wash it with deionized water, and finally vacuum-dry the product at room temperature for 24 hours to obtain an organic-inorganic hybrid catalyst.

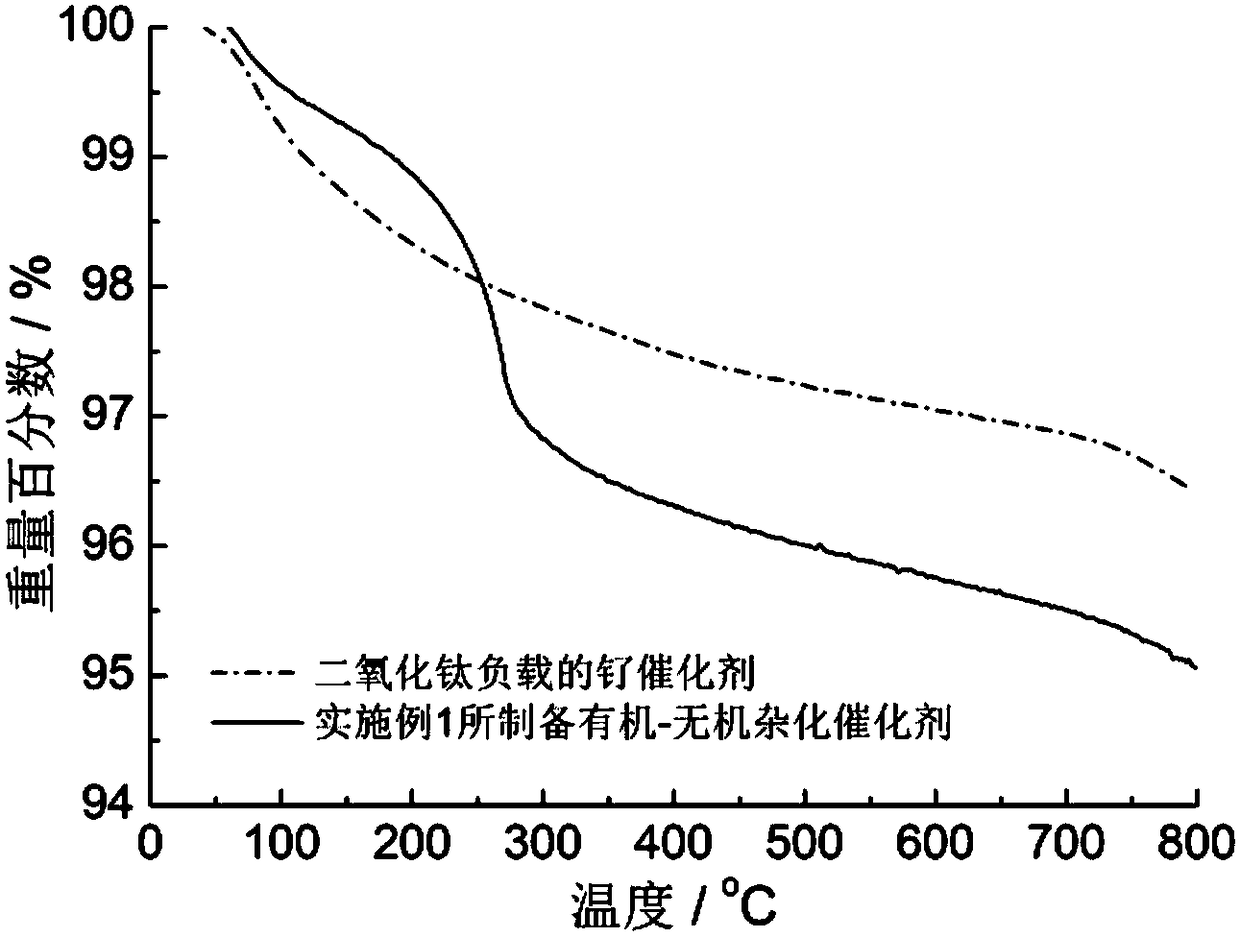

[0026] figure 1 Schematic diagram of the immobilization method for small molecule ligands containing secondary and / or tertiary amine groups. image 3 For the thermogravimetric analysis curve of the organic-inorganic hybrid catalyst prepared in the above examples in air, as the temperature increases, the organic components are continuously oxidized and decomposed, and finally only t...

Embodiment 2

[0028] Weigh 27mg small molecule ligand L2 (see attached figure 2 ) into the reaction flask filled with 6mL ethyl acetate, stirred vigorously until completely dissolved, and added 648mg of titanium dioxide-supported ruthenium catalyst in the above-mentioned reaction flask. After maintaining stirring for 6 hours, the mixture was transferred to a centrifuge tube containing 6 mL of water. Centrifuge at 5000 rpm for 30 minutes, collect the centrifuged solid and wash it with deionized water, and finally vacuum-dry the product at room temperature for 36 hours to obtain an organic-inorganic hybrid catalyst.

[0029] Thermogravimetric analysis showed that the content of the small molecule ligands in the organic-inorganic hybrid catalyst prepared in the above examples was 1.0 wt%.

Embodiment 3

[0031] Weigh 75mg small molecule ligand L3 (see attached figure 2 ) was added to the reaction flask filled with 6mL of n-pentane, vigorously stirred until completely dissolved, and 300mg of titanium dioxide-supported ruthenium catalyst was added in the above-mentioned reaction flask. After maintaining stirring for 2 hours, the mixture was transferred to a centrifuge tube containing 6 mL of water. Centrifuge at 5000 rpm for 30 minutes, collect the centrifuged solid and wash it with deionized water, and finally vacuum-dry the product at room temperature for 24 hours to obtain an organic-inorganic hybrid catalyst.

[0032] Thermogravimetric analysis showed that the content of the small molecule ligand in the organic-inorganic hybrid catalyst prepared in the above example was 1.2 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com