Fixed type double-station double-welding-robot workstation

A dual-station, dual-welding technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as scrap, workpiece verticality, and easy offset during spot welding. Strength, convenient welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

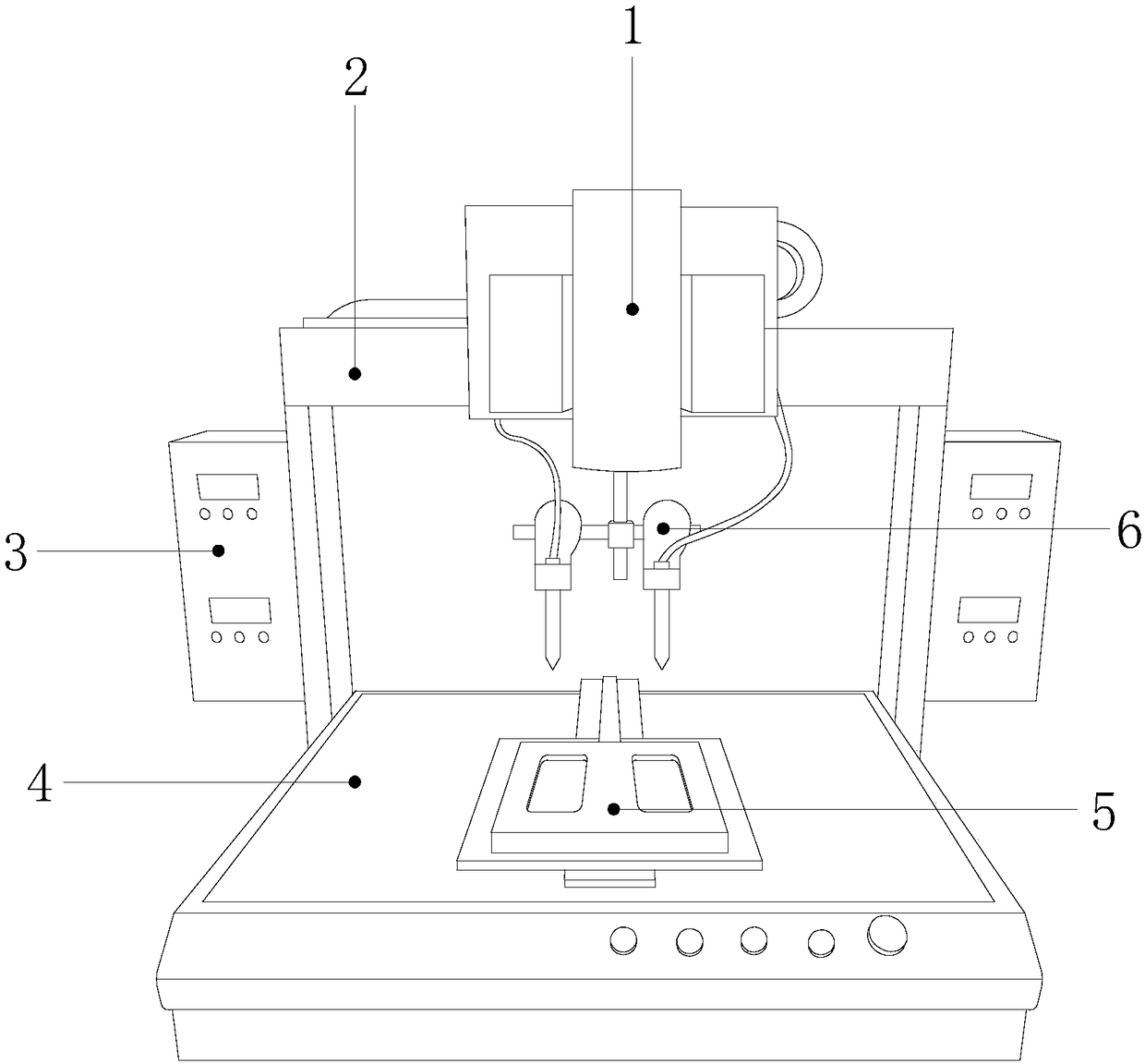

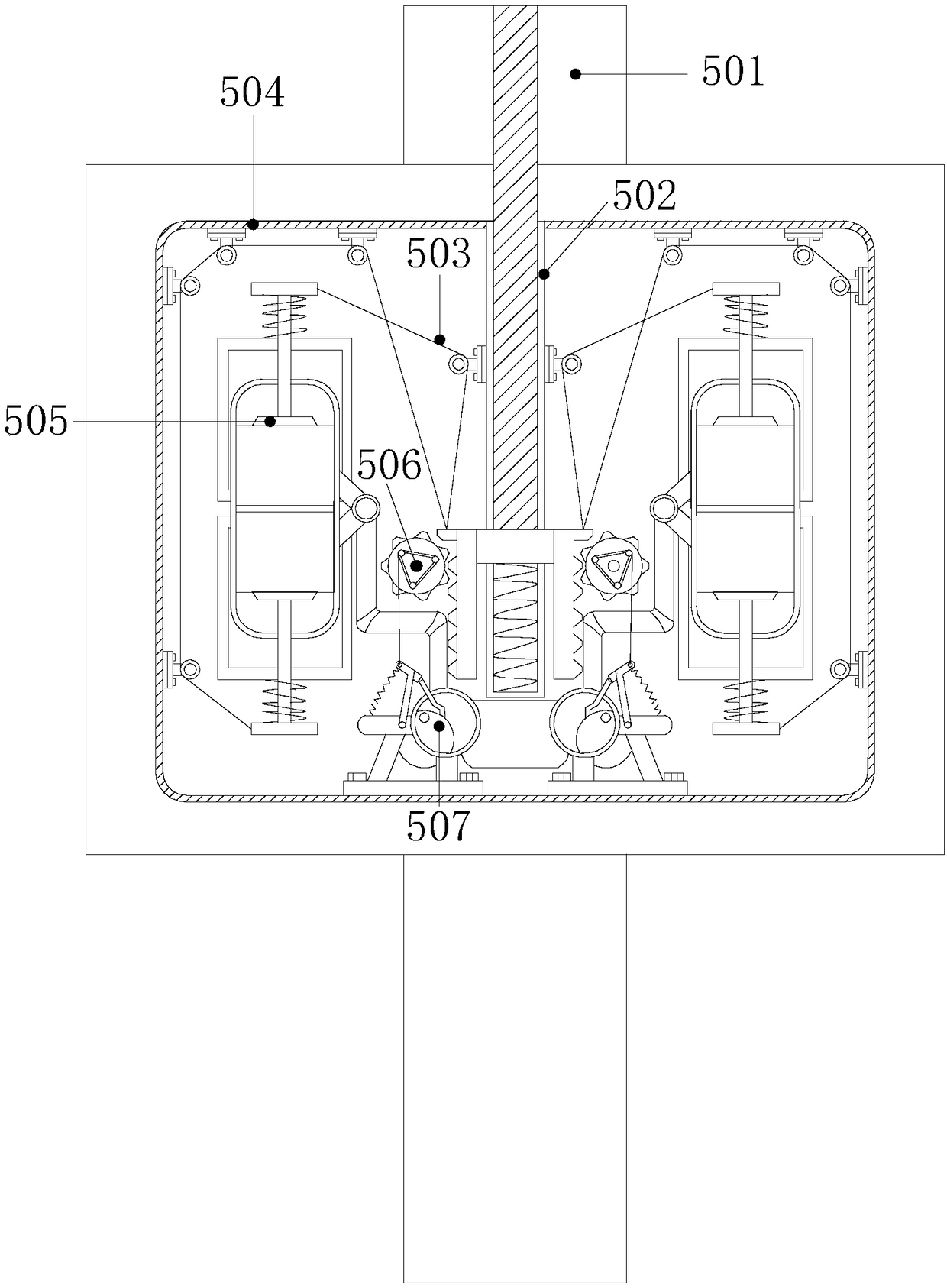

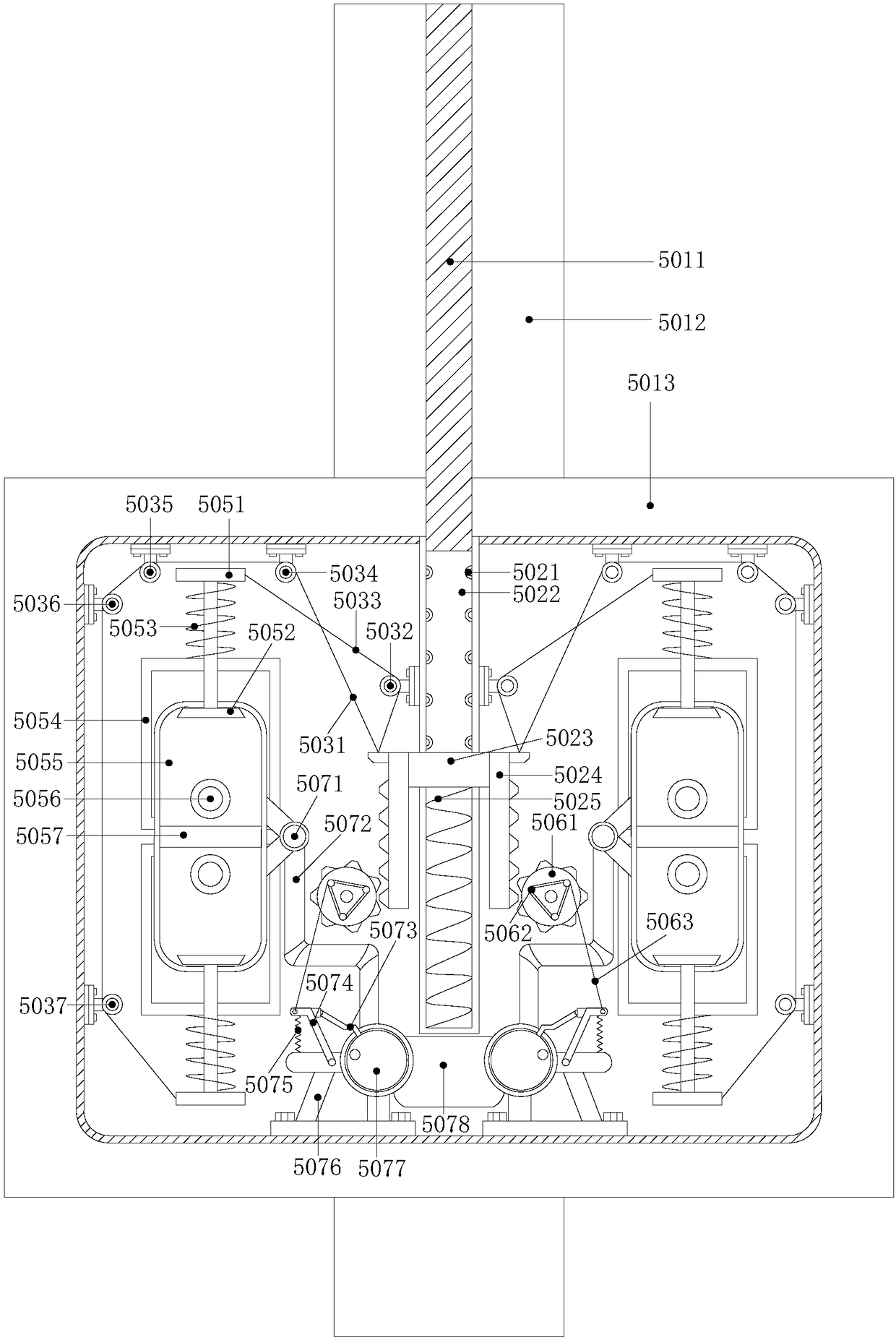

[0019] see Figure 1-Figure 3, the present invention provides a fixed double-station double-welding robot workstation, the structure of which includes a welding spindle 1, a gantry 2, a controller 3, a processing table 4, a double-station fixture 5, and an electric welding pen 6. The gantry 2 passes through The fastening method is installed on the rear ends of both sides of the processing table 4, the upper end of the processing table 4 is provided with a double-station jig 5, and the controller 3 is provided with two, and is installed on the left and right sides of the gantry 2 by a fastening method. The welding pen 6 is provided with two ends, and the upper end is fastened with the bottom of the welding main shaft 1, and the rear end of the middle part of the welding main shaft 1 is installed on the middle part of the gantry 2 by a fastening method, and the double-station jig 5 It includes a moving guide rail 501, a driving mechanism 502, a linkage mechanism 503, a casing 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com