Fixture for machining bolt ball on common lathe

A common lathe, bolt ball technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large operation error, affecting processing accuracy, time-consuming and laborious, and achieve fast and convenient process and improve processing accuracy. , the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

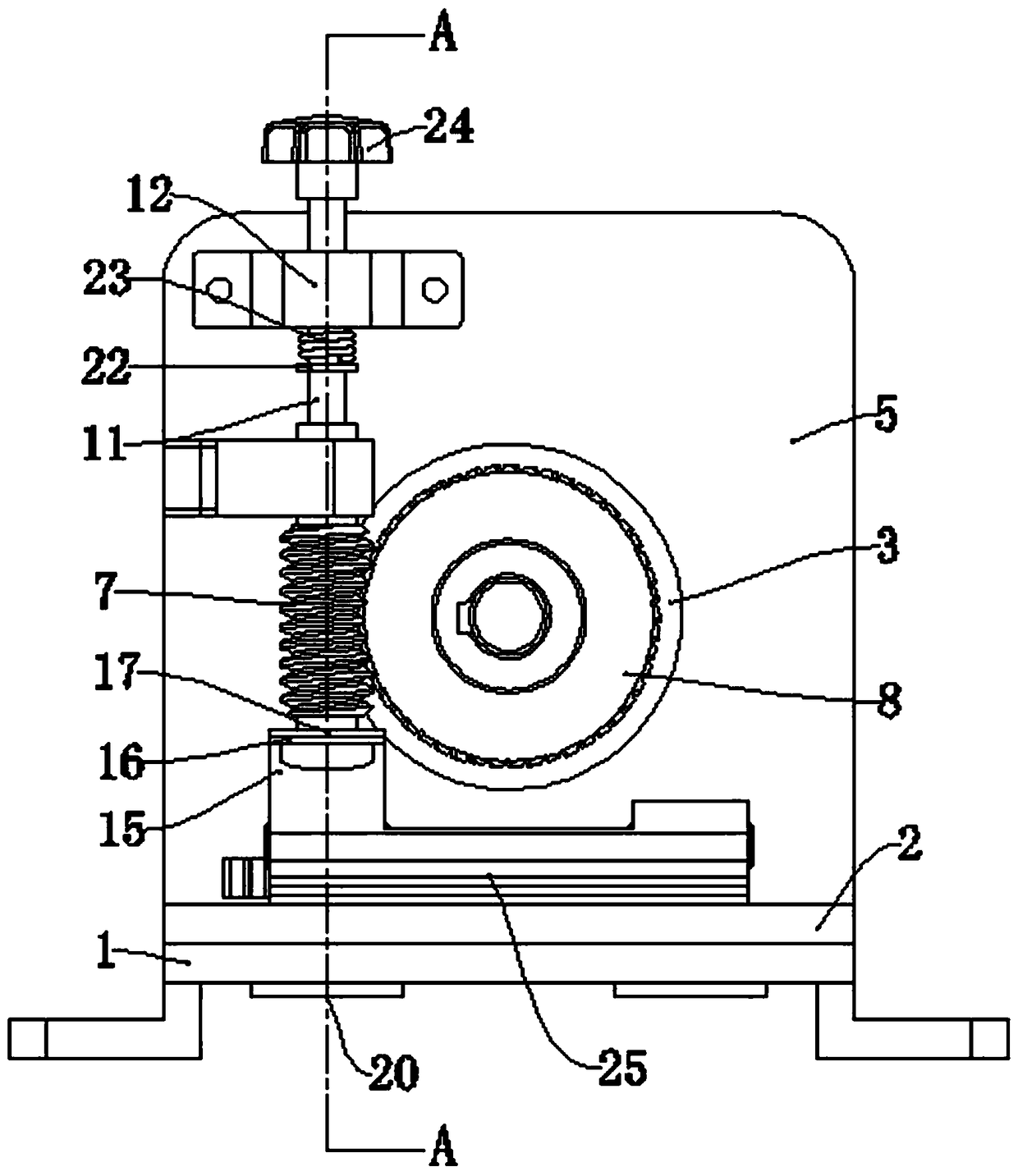

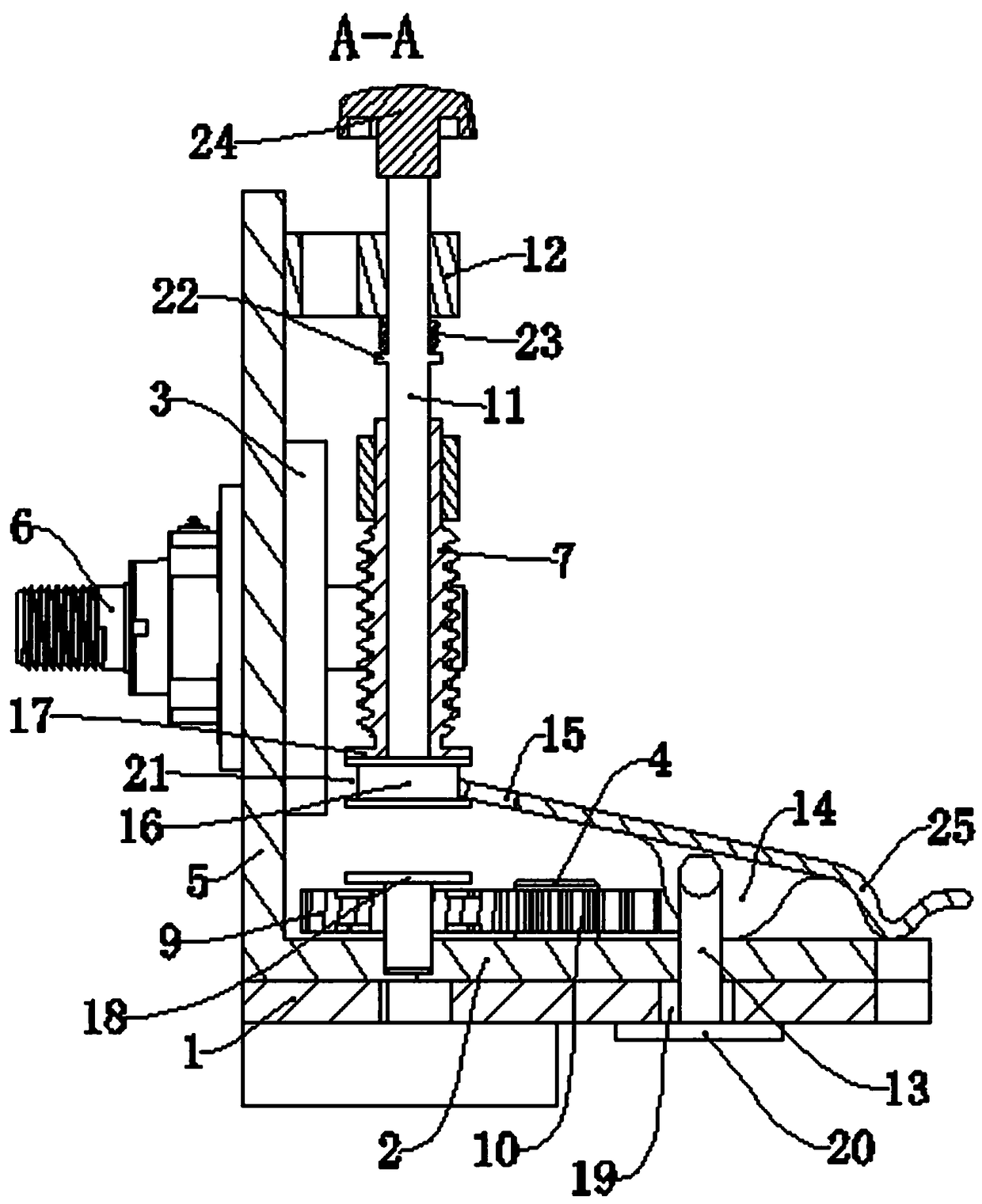

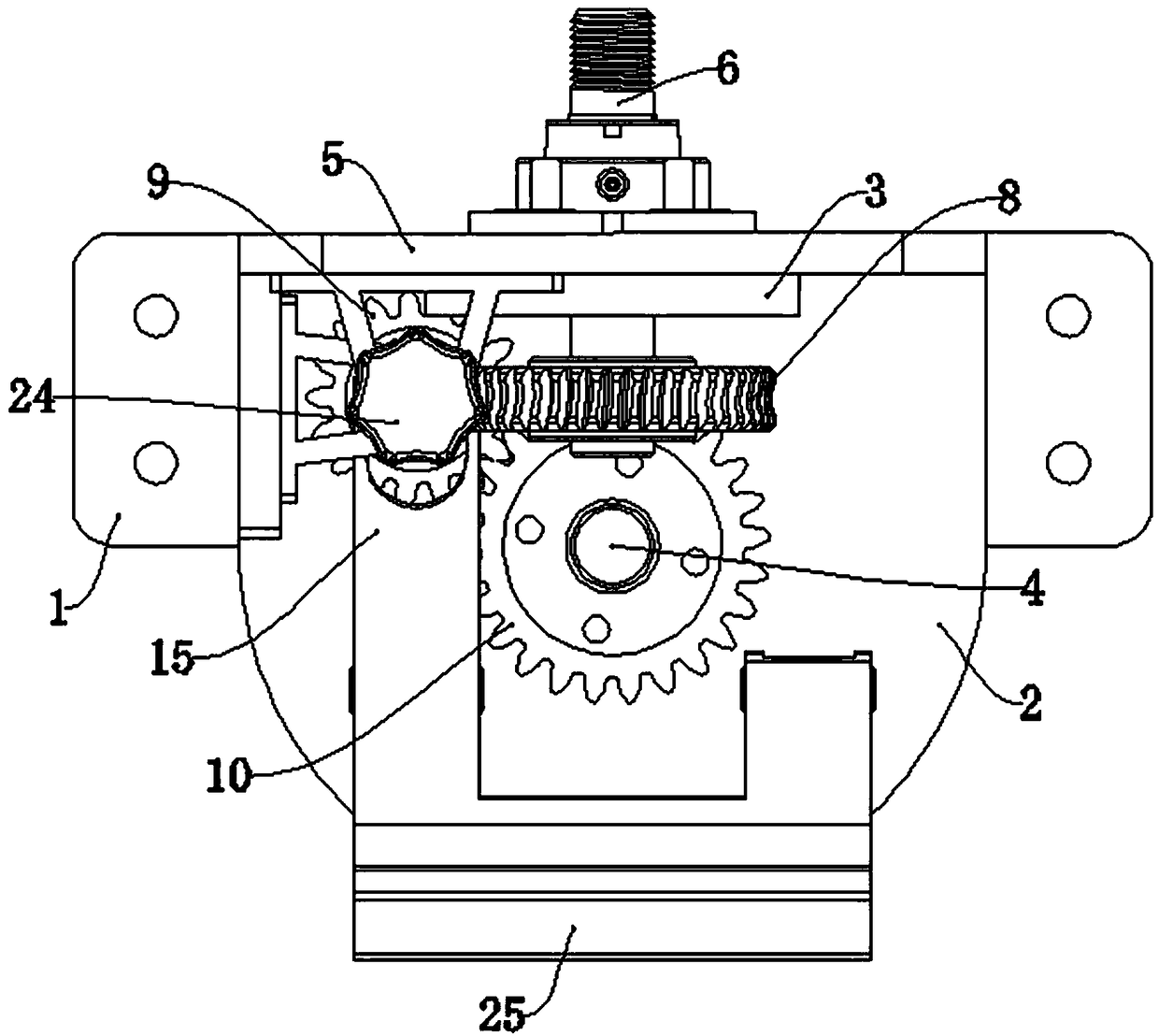

[0019] Figure 1 to Figure 7 It shows the fixture for processing bolt balls on ordinary lathes of the present invention, a fixture for processing bolt balls on ordinary lathes, including a base 1, a horizontal angle plate 2, a vertical angle plate 3, a worm 7, a worm wheel 8, and a planetary gear 9. Sun gear 10, transmission shaft 11, shaft sleeve 12, locking pin 13, eccentric wheel 14 and shift fork 15.

[0020] The top of the base 1 is fixed with a vertical shaft 4, and the horizontal angle disc 2 is slidably installed above the base 1 through the vertical shaft 4. The horizontal angle disc 2 can rotate around the vertical shaft 4 and can rotate along the axis of the vertical shaft 4. to swipe.

[0021] The horizontal angle plate 2 is provided with a vertical plate 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com