Lens mold pouring system

A mold casting and lens technology, which is applied to home appliances, other home appliances, packaging, etc., can solve the problems of low efficiency, monomer residue on the surface of the tape, and poor precision, so as to ensure the reliability of sealing, improve speed, and discharge good breath effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] Such as Figure 13 As shown, the state schematic diagram of the tearing of the lens mold in the present invention; the lens mold is composed of mold A50, mold B51 and adhesive tape 53 coated on the peripheral surfaces of molds A and B, and 54 in the figure is formed after the adhesive tape is torn. Tape-covered opening.

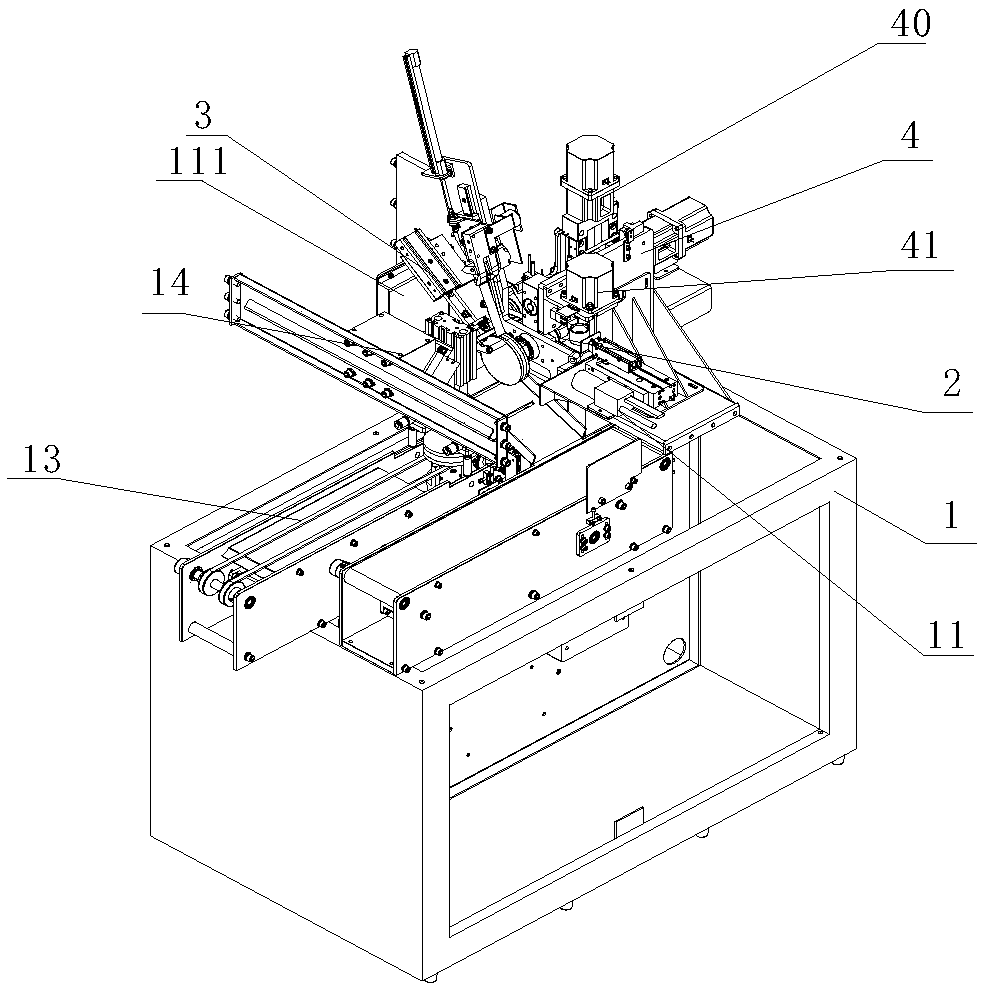

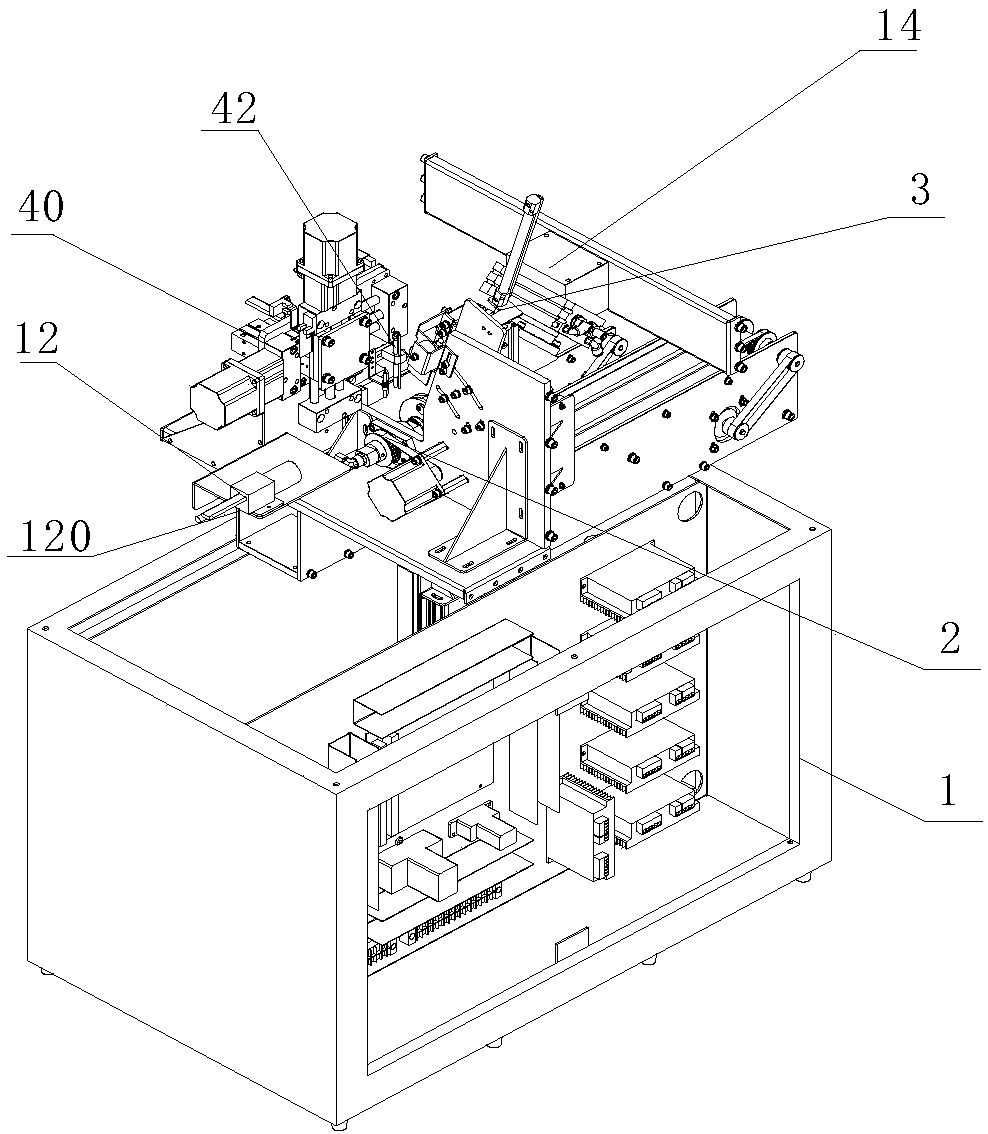

[0041] Such as figure 1 and figure 2 As shown, the lens mold pouring system includes a frame 1, on which a holding mechanism 2 is arranged, and the holding mechanism fixes the lens mold and drives it to rotate;

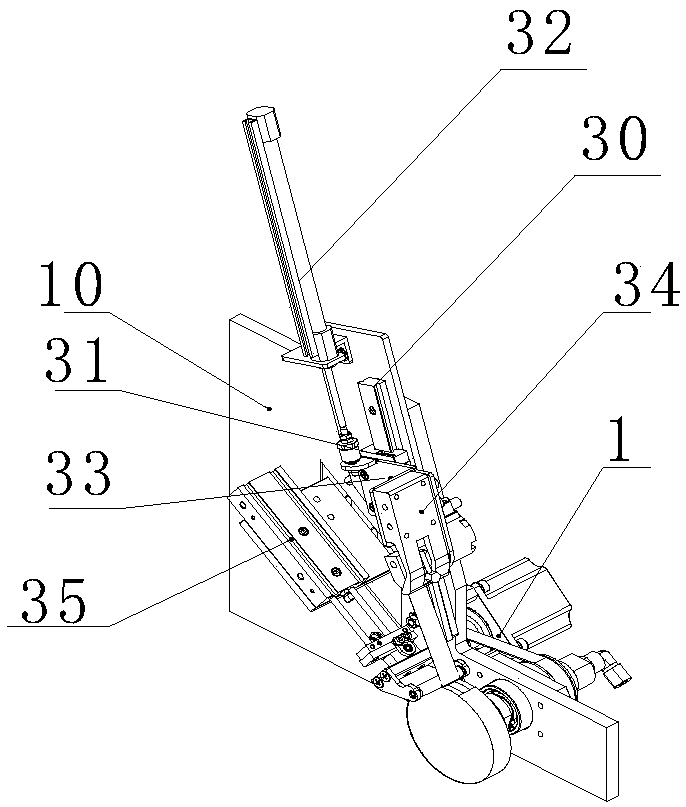

[0042]Tear sealing mechanism 3, the tear sealing mechanism is installed on the frame and is located at the side of the holding mechanism, the tear sealing mechanism is used to grab the end of the tape on the surface of the lens mold 5, and then separate the driving tape from the lens mold to form a An opening that is not covered b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com