Treatment method and device for waste sulfonated mud

A technology of treatment device and treatment method, applied in the fields of sludge treatment, oxidation treatment of sludge, chemical instruments and methods, etc., can solve the problems of unstable treatment, large residual amount, incomplete treatment of COD substances, etc. Waste of resources, obvious degradation effect, and the effect of improving the contact area of oxidative decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

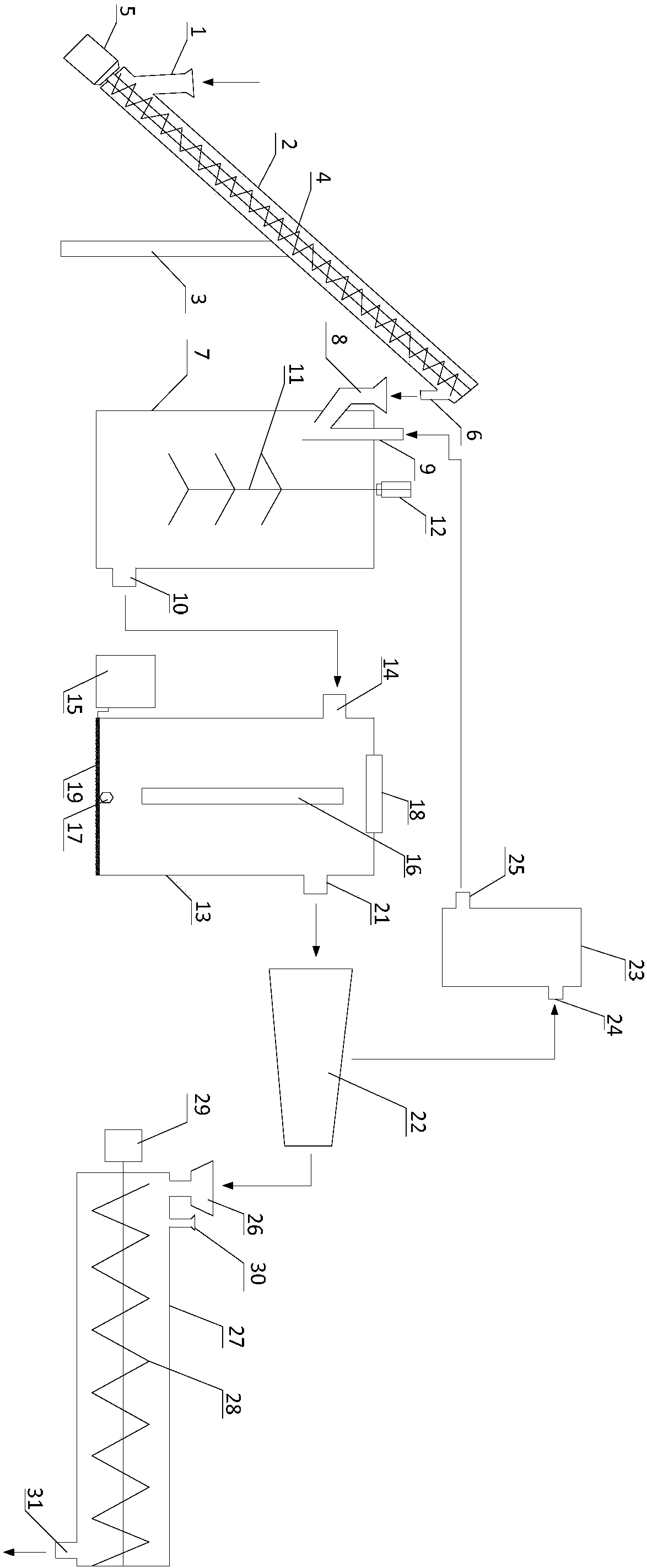

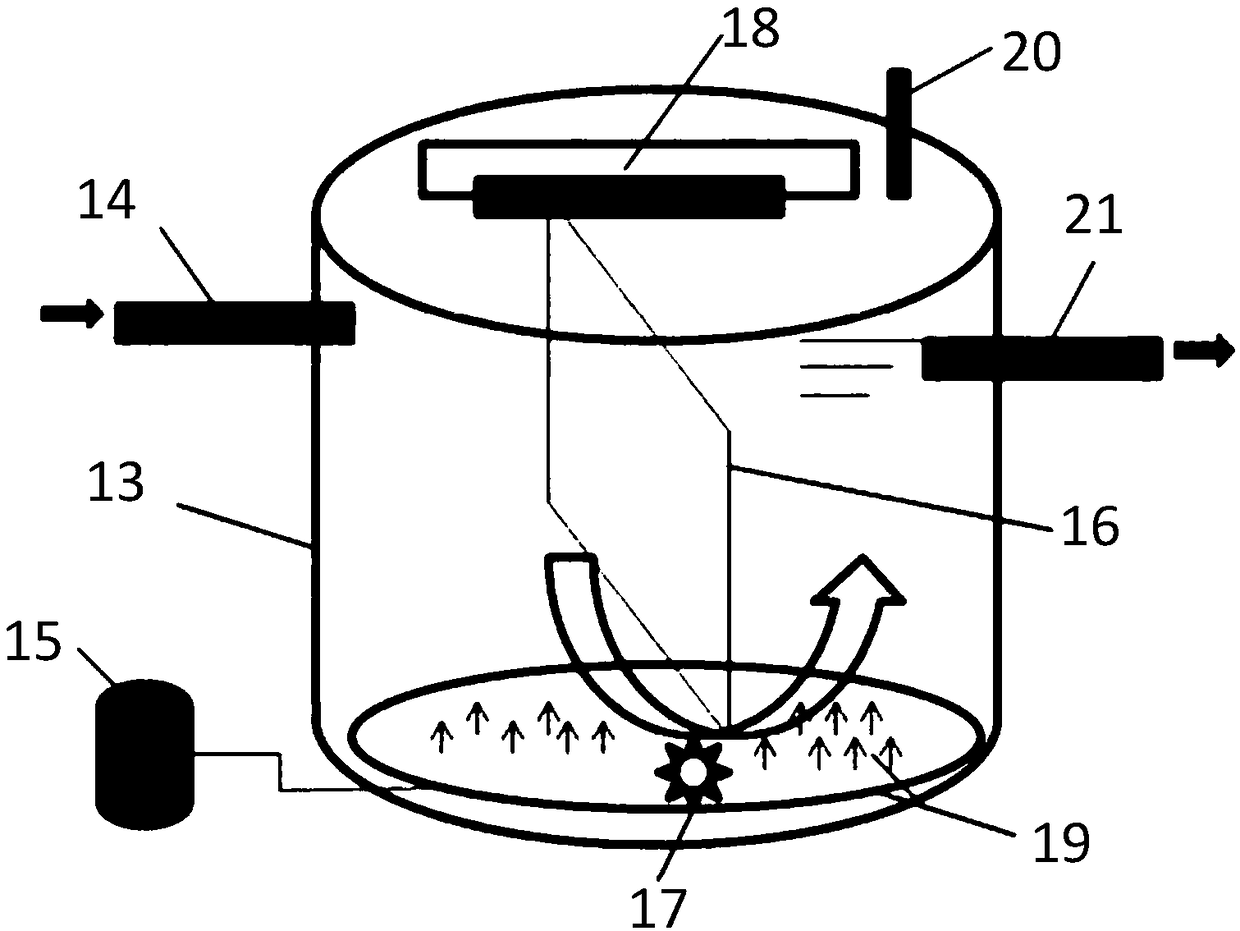

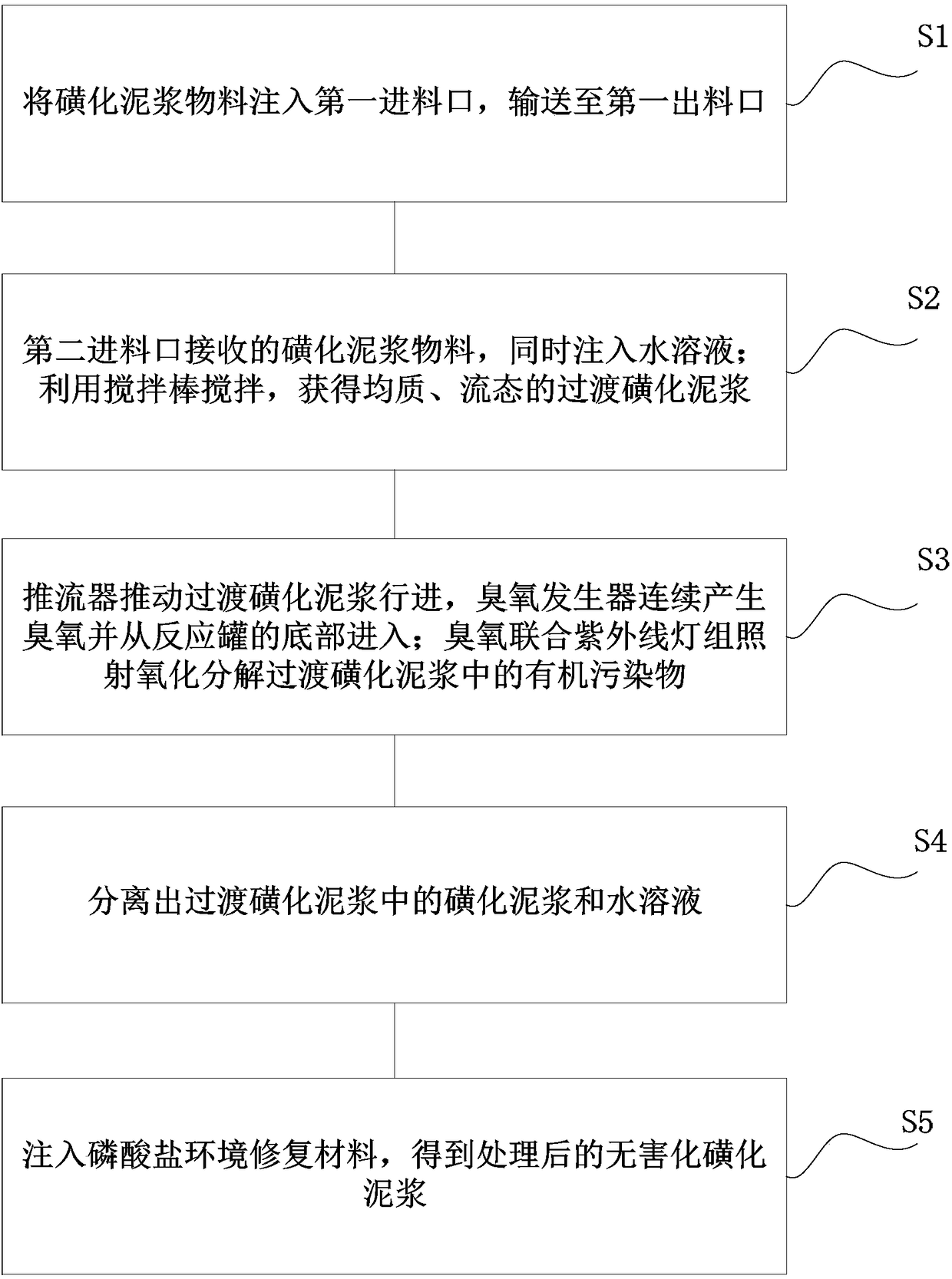

[0040] Such as Figure 1 to Figure 3As shown, this embodiment provides a waste sulfonated mud treatment device, which mainly solves the problems of high heat treatment energy consumption, high input cost, complicated tail gas treatment and incomplete treatment by chemical heat washing methods in the prior art. In addition, it should be noted that terms such as "first", "second", "third", and "fourth" involved in this embodiment are only used to distinguish similar components, and cannot be understood as special limitations on the scope of protection. Therefore, those skilled in the art may exchange or modify one or several of the serial numbers, which fall within the protection scope of the present invention. Specifically, the waste sulfonated mud processing device includes a feeding device for conveying crushed and screened sulfonated mud materials, the inlet is connected with the feeding device, and is used to receive the sulfonated mud materials delivered by the feeding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com