Method for biologically degrading polycyclic aromatic hydrocarbon phenanthrene by using aspergillus niger fungi

A polycyclic aromatic hydrocarbon phenanthrene and biodegradation technology, applied in the field of bioremediation of organic pollutants, can solve the problems of affecting the biodegradation of PAHs, low degradation efficiency, and unsatisfactory degradation speed, achieving huge economic and social benefits and good degradation effect , Improve the effect of degradation speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

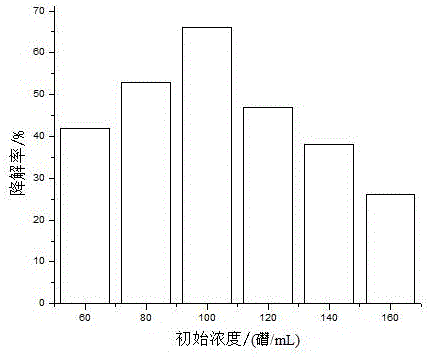

[0019] Embodiment 1: the selection of phenanthrene initial concentration

[0020] 1. Preparation of solid growth medium: chop 200g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double gauze and collect the filtrate, add 20g of glucose and 20g of agar to the filtrate, dilute to 1000mL with water, and divide into test tubes Medium, sterilized at 112-125°C for 20 minutes to make a solid growth medium (slope);

[0021] 2. Preparation of liquid growth medium: chop 200g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double gauze and collect the filtrate, add 20g of glucose to the filtrate, dilute to 1000mL with water, and dispense into 250mL Erlenmeyer flasks medium, 40mL per bottle, sterilized at 112-125°C for 20min to make a liquid growth medium;

[0022] 3. Preparation of liquid nutrient-limited medium: chop 100g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double-layer gauze and collect the filtrate, add 10g o...

Embodiment 2

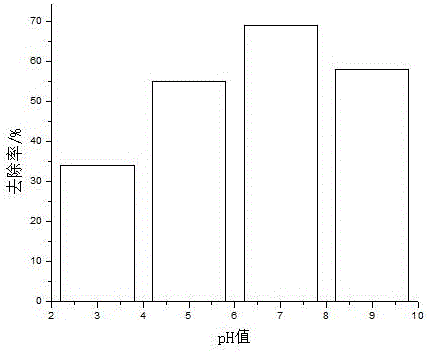

[0026] Example 2: Effect of pH on Degradation

[0027] 1. Preparation of solid growth medium: chop 200g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double gauze and collect the filtrate, add 20g of glucose and 20g of agar to the filtrate, dilute to 1000mL with water, and divide into test tubes Medium, sterilized at 112-125°C for 20 minutes to make a solid growth medium (slope);

[0028] 2. Preparation of liquid growth medium: chop 200g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double gauze and collect the filtrate, add 20g of glucose to the filtrate, dilute to 1000mL with water, and dispense into 250mL Erlenmeyer flasks medium, 40mL per bottle, sterilized at 112-125°C for 20min to make a liquid growth medium;

[0029] 3. Preparation of liquid nutrient-limited medium: chop 100g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double-layer gauze and collect the filtrate, add 10g of glucose to the filtrate, ...

Embodiment 3

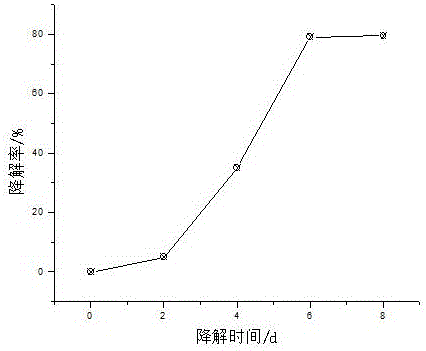

[0033] Embodiment 3: Determination of optimal degradation time

[0034]1. Preparation of solid growth medium: chop 200g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double gauze and collect the filtrate, add 20g of glucose and 20g of agar to the filtrate, dilute to 1000mL with water, and divide into test tubes Medium, sterilized at 112-125°C for 20 minutes to make a solid growth medium (slope);

[0035] 2. Preparation of liquid growth medium: chop 200g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double gauze and collect the filtrate, add 20g of glucose to the filtrate, dilute to 1000mL with water, and dispense into 250mL Erlenmeyer flasks medium, 40mL per bottle, sterilized at 112-125°C for 20min to make a liquid growth medium;

[0036] 3. Preparation of liquid nutrient-limited medium: chop 100g of peeled potatoes, add 1000mL of water, boil for 30min, filter with double-layer gauze and collect the filtrate, add 10g of glucose t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com