Positioning device and positioning method for producing basalt fiber particle rope

A technology of basalt fiber and positioning device, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc. It can solve the problems of uncontrollable quality of basalt fiber particle rope, quality influence of basalt fiber particle rope, and influence of engineering plastic particle fixation and other issues, to achieve precise positioning, reduce the impact of product quality, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

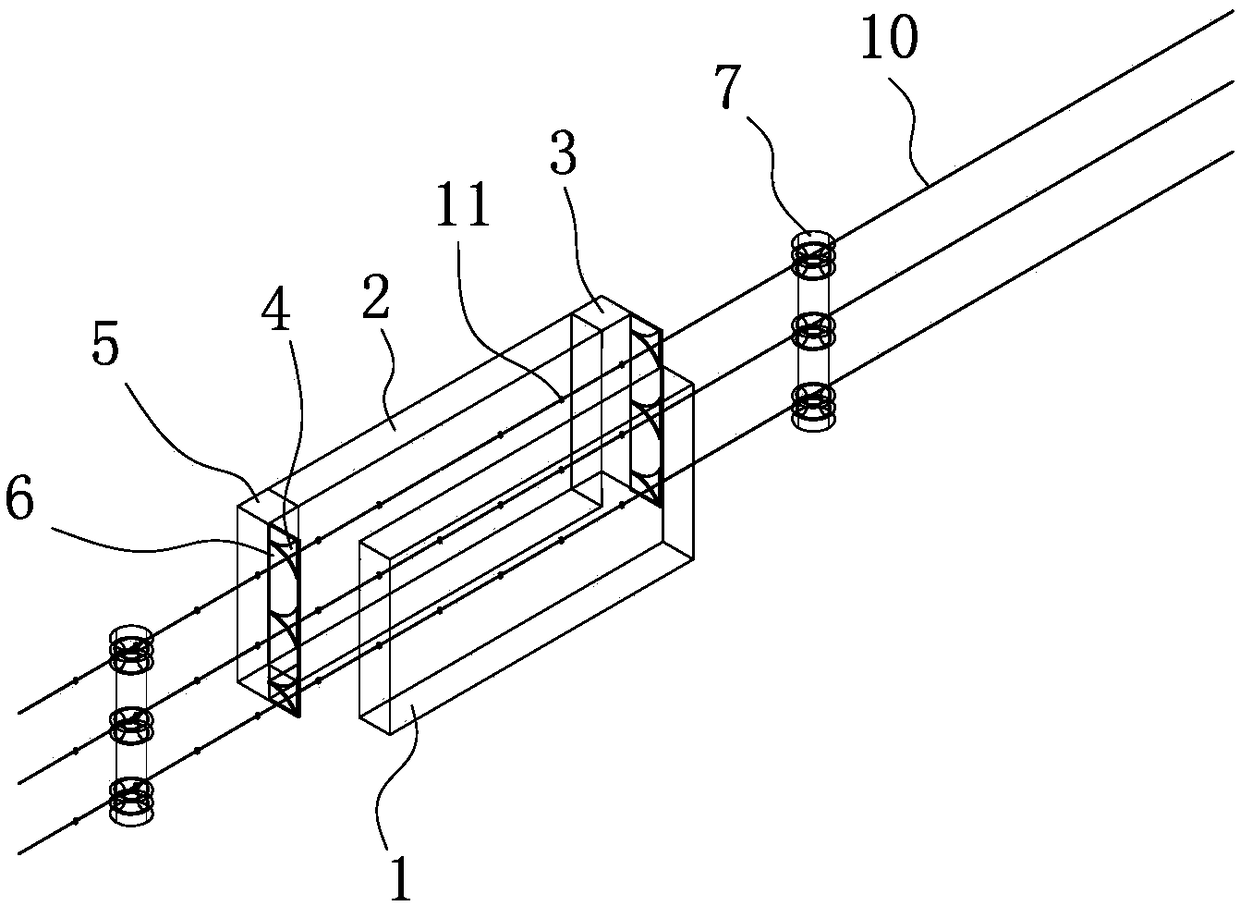

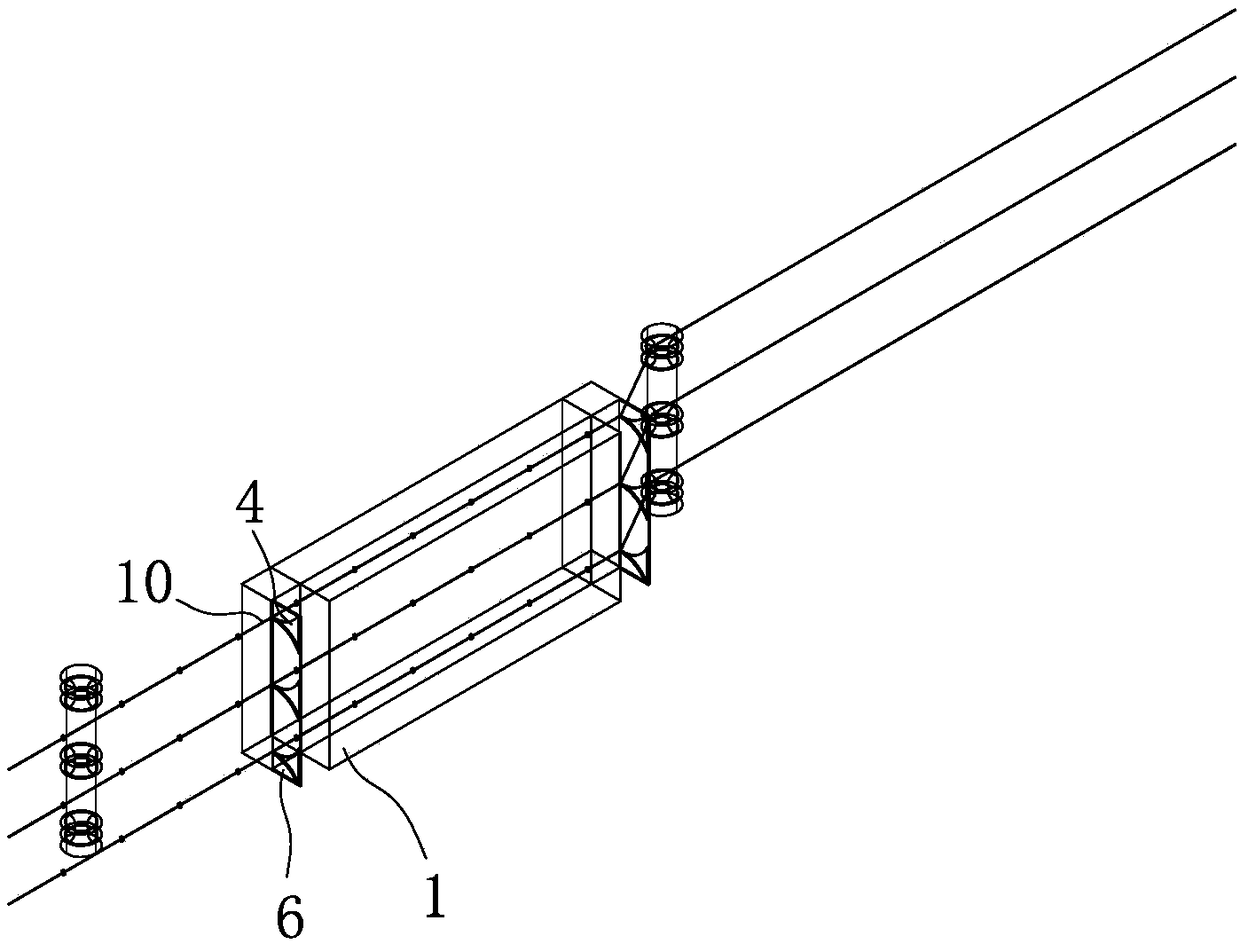

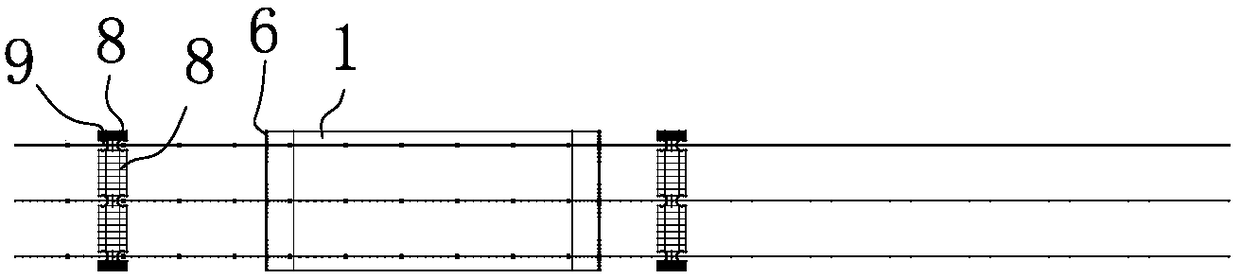

[0032] Such as figure 1 As shown, a positioning device for producing basalt fiber particle ropes includes a female mold 1 and a male mold 2 that are compatible with each other. The male mold 2 is provided with an injection port, and the injection port is connected to the spray gun of the injection molding machine. When the male mold 2 and the female mold 1 close to each other to form mold closing, a plurality of cavities connected to the injection molding ports are formed between the male mold 2 and the female mold 1, and plastic particles 11 are formed in the cavities. The material for making plastic particles can be ABS , PC or PA etc.

[0033] The two ends of male mold 2 are provided with a fiber rope locator 3 respectively, and fiber rope locator 3 can move synchronously with male mold, and described fiber rope locator 3 is provided with some positioning holes 4, and described positioning hole 4 The cross-sectional area of the fiber rope gradually increases from the mal...

Embodiment 2

[0041] This embodiment is a positioning method for producing basalt fiber particle ropes according to the positioning device for producing basalt fiber particle ropes provided in Example 1. Several fiber ropes are passed through the positioning holes in the two fiber rope positioners 3 on the male mold 2 successively. 4. The two positioning holes 4 through which each fiber rope 10 passes are respectively located on two different fiber rope positioners 3 and the two positioning holes 4 correspond to each other. The male mold 2 moves closer to the female mold 1 to close the mold, and the fiber rope The rope 10 snaps into the bottom of the positioning hole 4 to position the fiber rope. After the mold is closed, it is injected, and the plastic enters the cavity to form plastic particles 11 and is fixed on the fiber rope. After cooling, the male mold 2 leaves the female mold 1 The mold opening state is formed, the fiber rope is separated from the bottom of the positioning hole 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com