Multi-temperature zone refrigerator with pulse-tube free-piston Stirling refrigerator

A refrigerator, multi-temperature zone technology, applied in refrigerators, household refrigerators, household refrigeration devices, etc., to reduce manufacturing difficulty, eliminate pumping loss, and increase efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

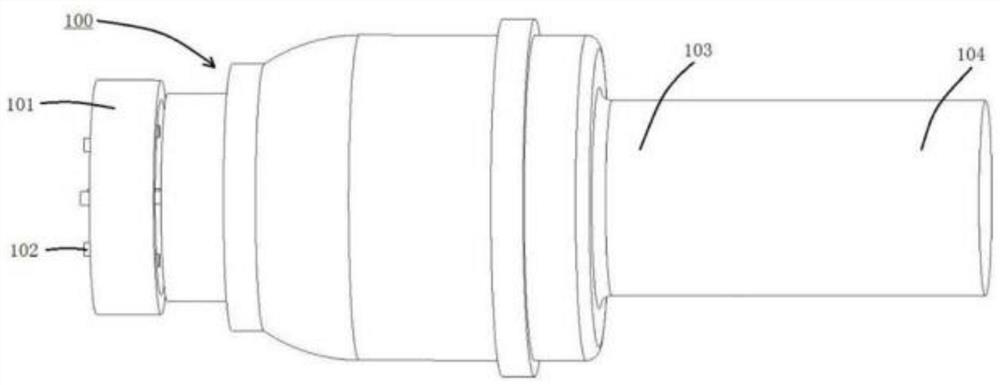

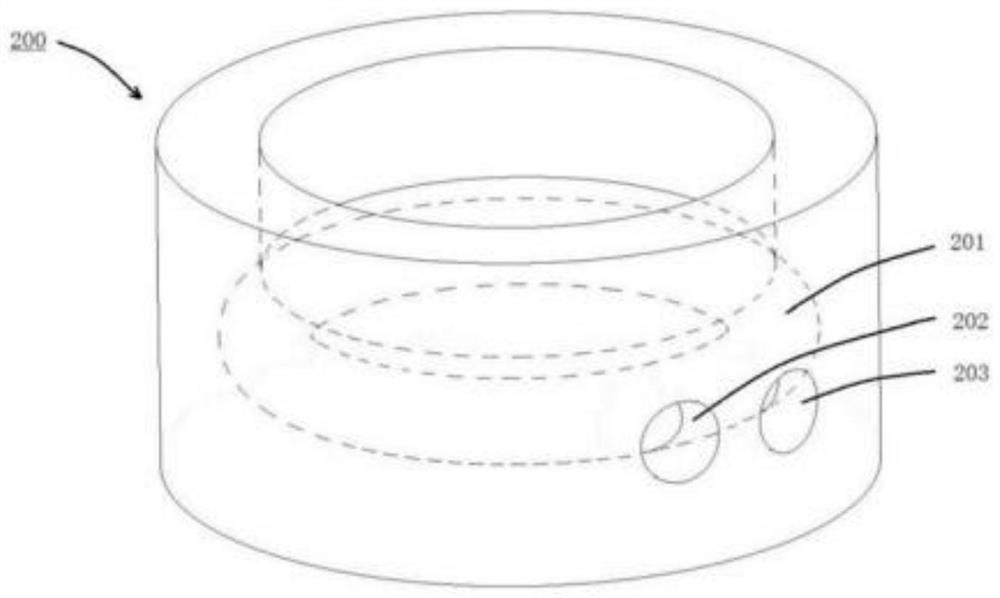

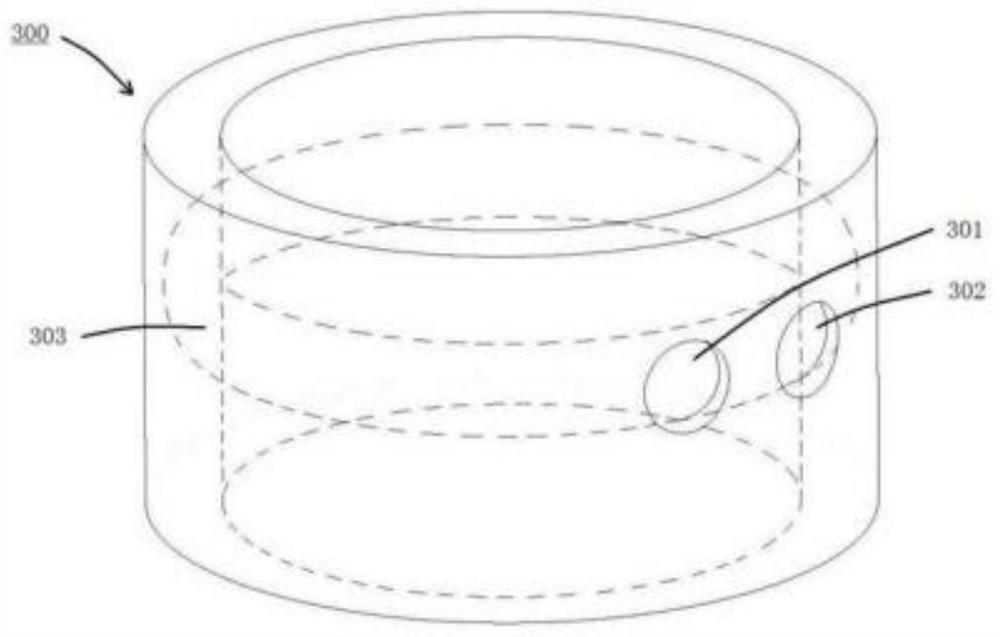

[0038] Such as Figure 1 to Figure 9 As shown, a multi-temperature zone refrigerator combining a Stirling refrigerator and compression throttling refrigeration includes a refrigerator box 700 and a refrigeration system. The refrigerator box 700 includes a refrigerator shell 706 , a display screen 707 , a refrigerator door 708 , and a heat insulating layer 705 . Casing interior space has refrigerating chamber 701, is positioned at refrigerator top half, freezer chamber 703, is positioned at the right side of refrigerator bottom half, variable chamber 702, is positioned at refrigerator bottom half left side, and each room has storage board 704. The display screen 707 is connected to the controller 800, which can not only display the temperature in each refrigeration room, but also control the operating frequency of the variable frequency compressor 608 and the input voltage of the free-piston Stirling refrigerator 100, so as to effectively control the refrigeration temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com