Embedded chip packaging method adopting glue spraying at groove bottoms

A chip packaging and glue spraying technology, used in semiconductor/solid-state device parts, electrical components, electric solid-state devices, etc., can solve the problem that the chip that cannot be DAF film is removed from the cutting film, the cost of DAF film material is high, and it cannot be embedded. Chip and other problems, to achieve the effect of low cost, fast operation efficiency, and reduced chip spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention. The components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments.

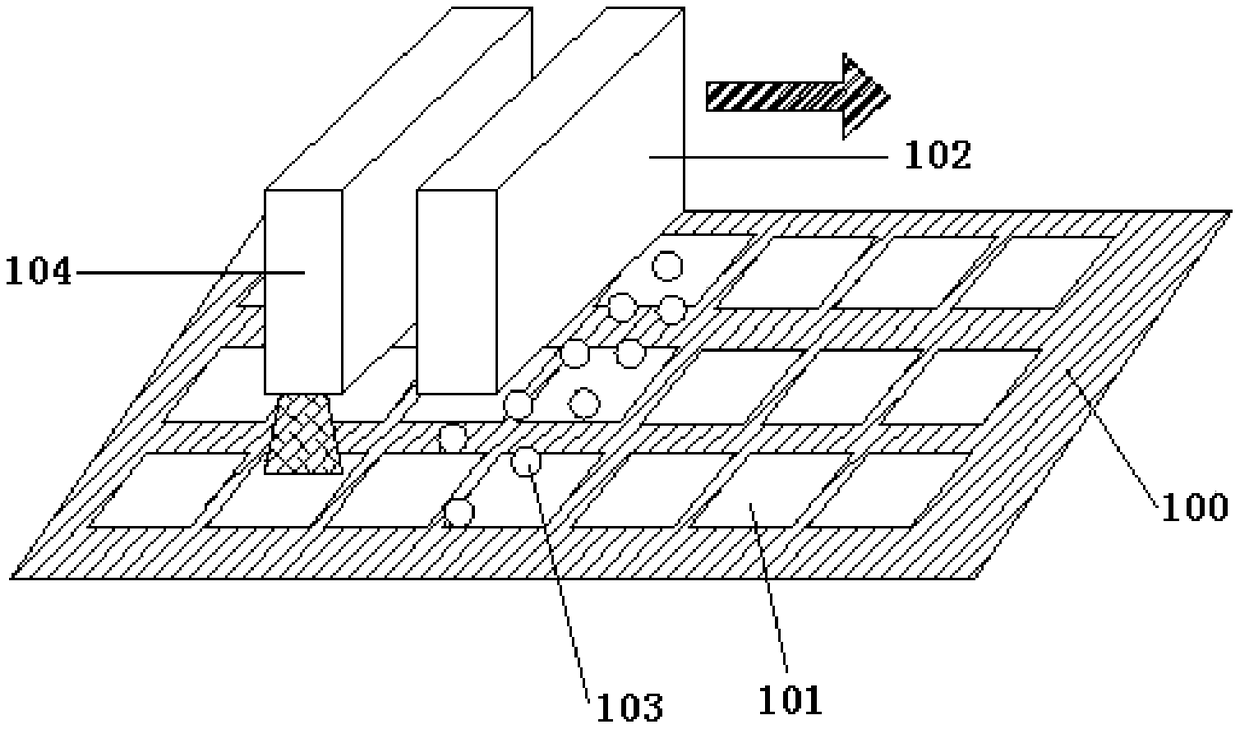

[0028] Such as figure 1 As shown, an embedded chip packaging method of spraying glue at the bottom of the groove is implemented according to the following steps:

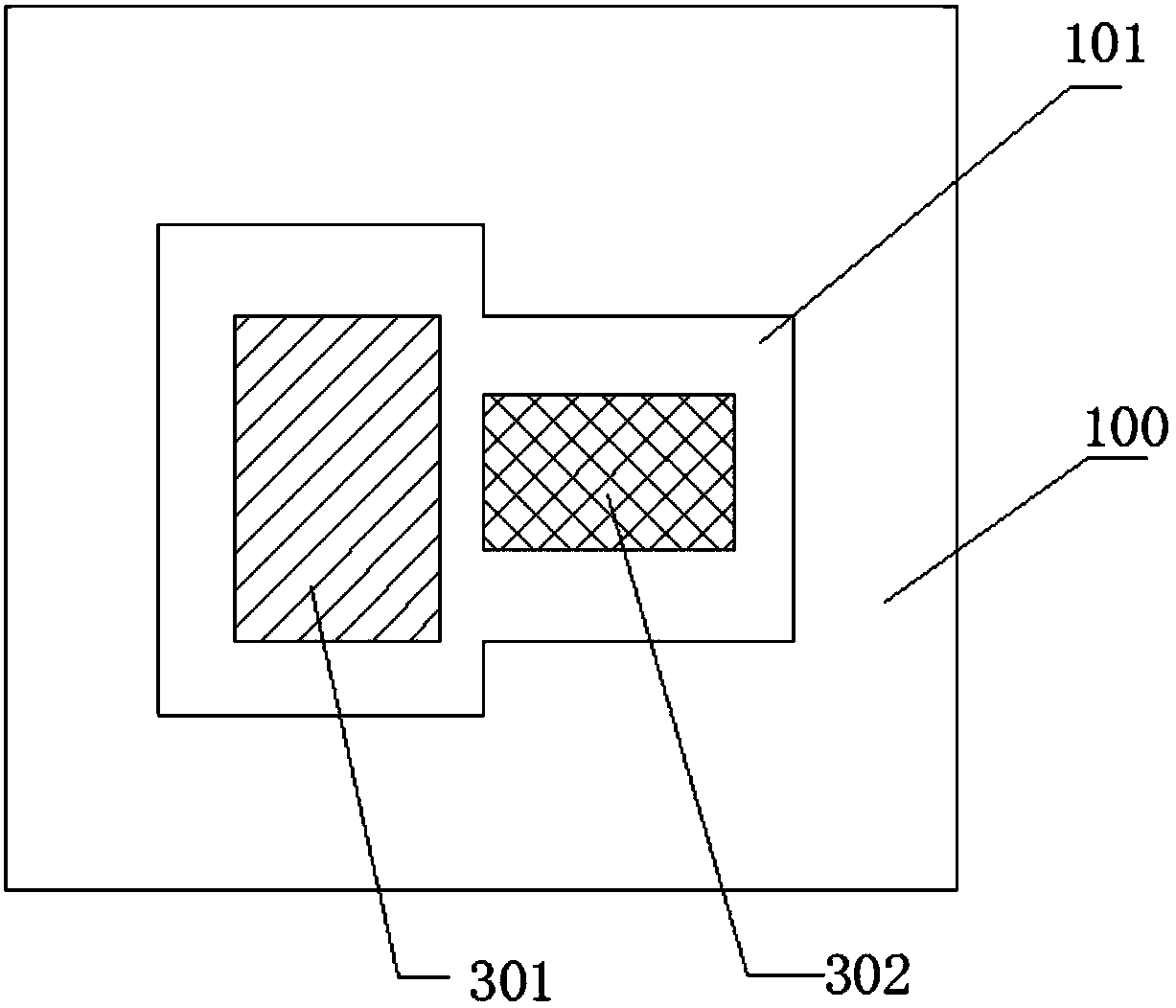

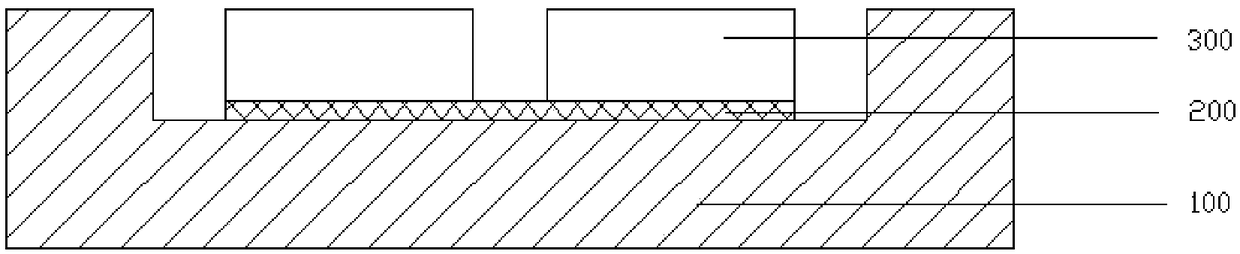

[0029] A. Etch a groove 101 on the substrate 100 by an etching method;

[0030] B. Use glue spraying equipment to spray UV glue in the groove, and control the glue spraying head 102 of the glue spraying equipment to spray UV glue to the bottom of the groove in the form of glue droplets 103 for attaching chips , and control the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com