TFT array substrate and manufacturing method thereof

A technology for array substrates and manufacturing methods, applied in the field of TFT array substrates and their manufacture, can solve the problems of long production time, high production cost, low mobility, etc., and achieve the effects of saving production time, saving production costs, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

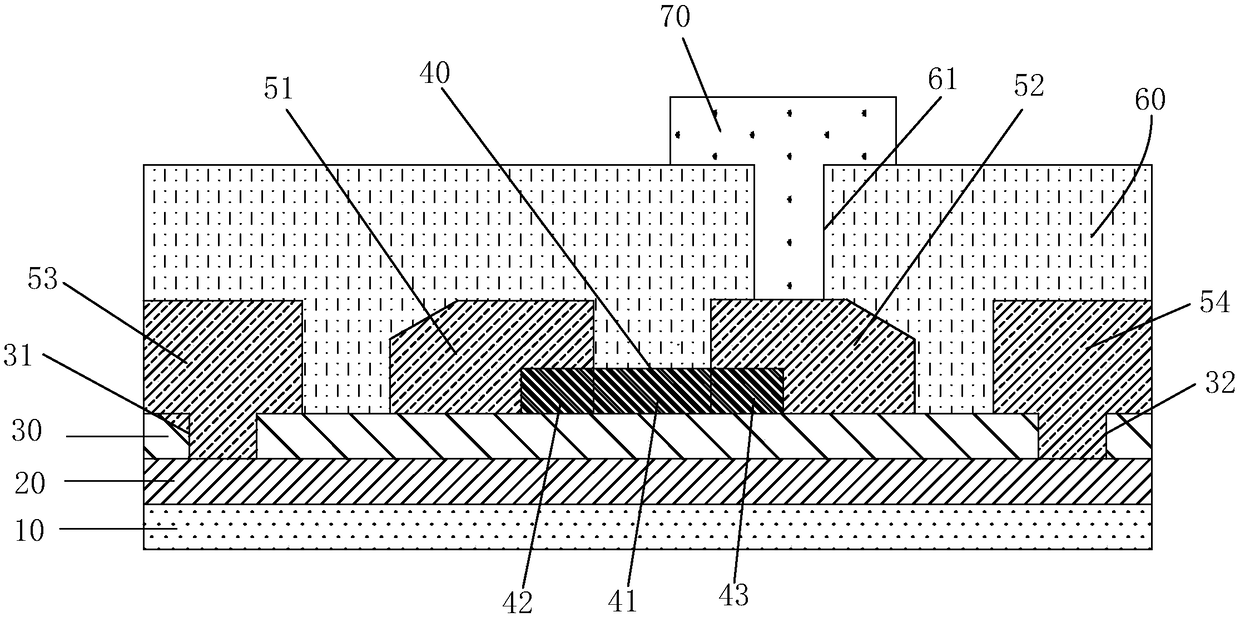

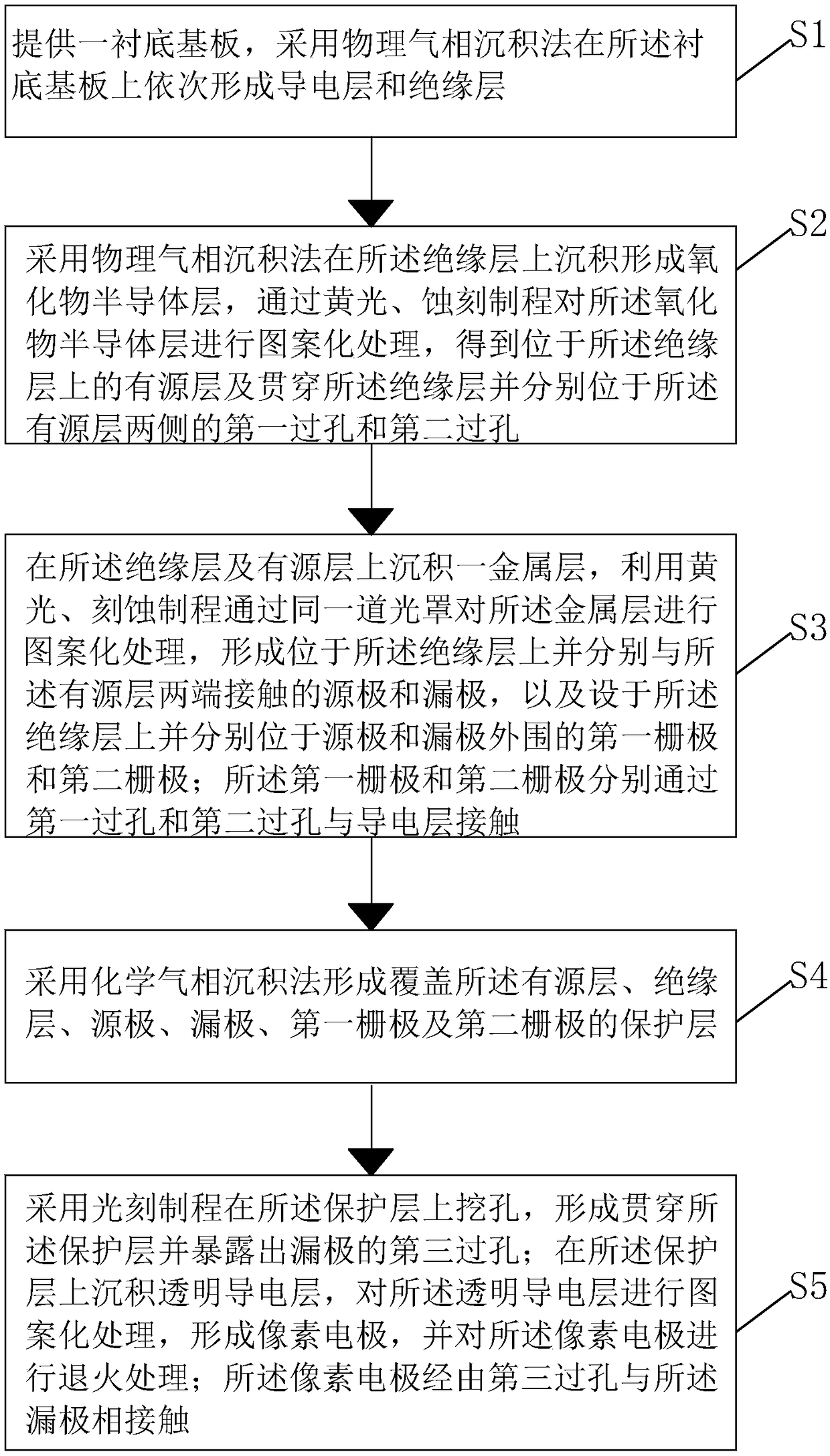

[0042] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0043] see figure 1, the present invention provides a TFT array substrate, including a base substrate 10, a conductive layer 20 disposed on the base substrate 10, an insulating layer 30 disposed on the conductive layer 20, and an insulating layer 30 disposed on the insulating layer 30. The active layer 40 on the upper surface, the source electrode 51 and the drain electrode 52 arranged on the insulating layer 30 and in contact with both ends of the active layer 40 respectively, and the source electrode 51 arranged on the insulating layer 30 and respectively located at the source electrode 51 and the first gate 53 and the second gate 54 on the periphery of the drain 52;

[0044] The first gate 53 and the second gate 54 are respectively in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com