Oxide semiconductor thin film and preparation process thereof

A technology of oxide semiconductor and preparation process, which is applied in the direction of semiconductor devices, transistors, electrical components, etc., can solve the problems of lower annealing temperature, high preparation cost, and non-environmental protection, and achieve low annealing temperature, lower process cost, and high anti-aging sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation technology of oxide semiconductor thin film, thin composition is M2x In 2-2x o 3-δ And the composition does not include Zn and Sn, where M is a group IIIB element in the periodic table of elements, 0.001≤x≤0.3, 0≤δ<3, the aqueous solution of In salt and M salt is used as the precursor solution for hydrolysis reaction, and then The solution after the hydrolysis reaction is formed into a film, and annealed at a temperature not higher than 300 degrees Celsius after the film is formed.

[0045] Group IIIB elements are one or any combination of two or more of Sc, Y, Ac, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, or Lu Elements. It is preferably Nd or Sc, more preferably Sc.

[0046] The solute of the aqueous solution is one of nitrate, chloride, hydroxide or perchlorate. It is better for the solute of the aqueous solution to contain both nitrate and perchlorate.

[0047] The solute of the aqueous solution can also be at least two subst...

Embodiment 2

[0065] A method for preparing an oxide semiconductor film, the chemical formula of the composition of the oxide semiconductor film is expressed as Nd 2x In 2-2x o 3-δ , There are three options for x: 0.02, 0.05 and 0.1. The precursor solution is an aqueous solution of indium chloride and neodymium chloride, which is formed into a film by spin coating, followed by UV treatment, and then annealed at 180 degrees Celsius in an air atmosphere.

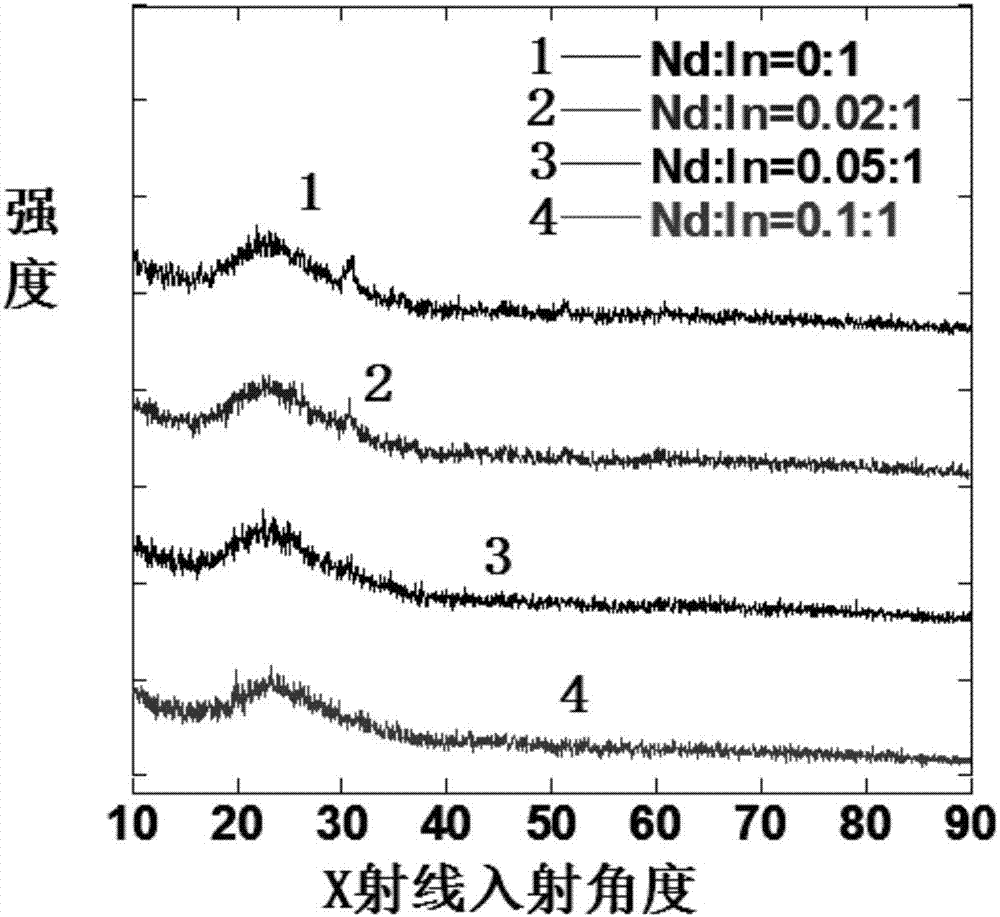

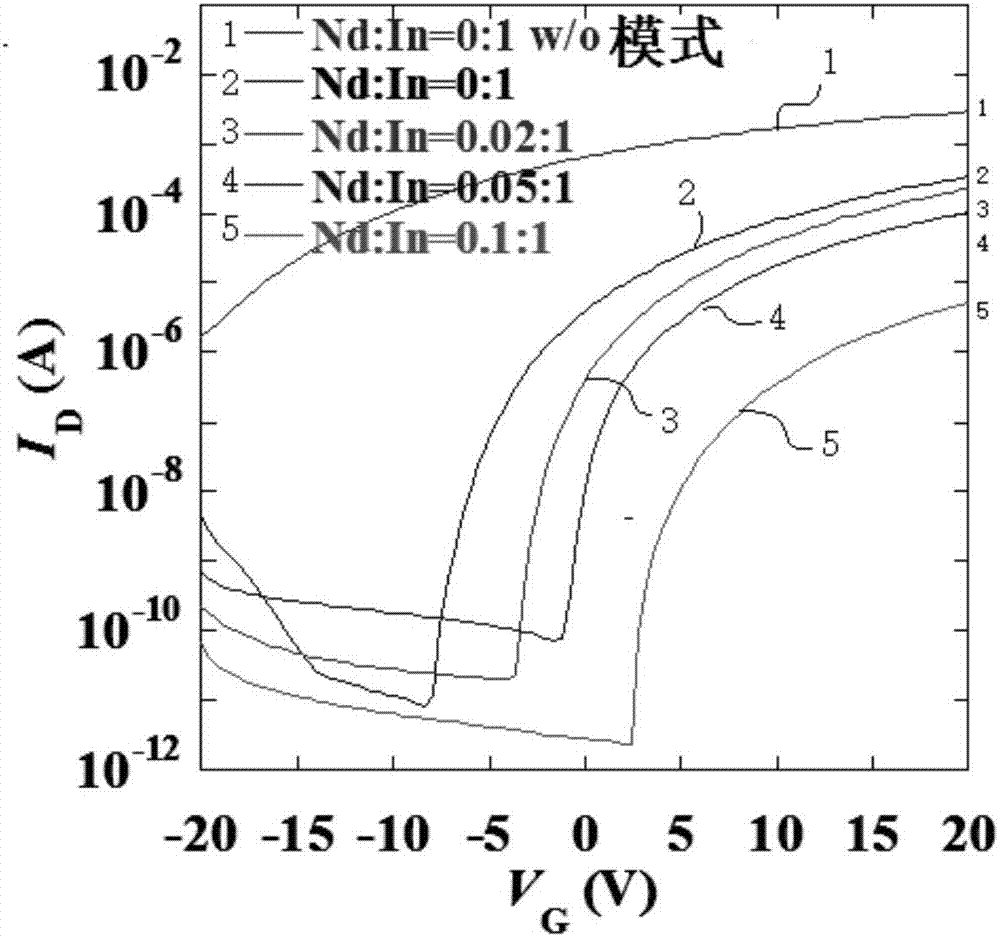

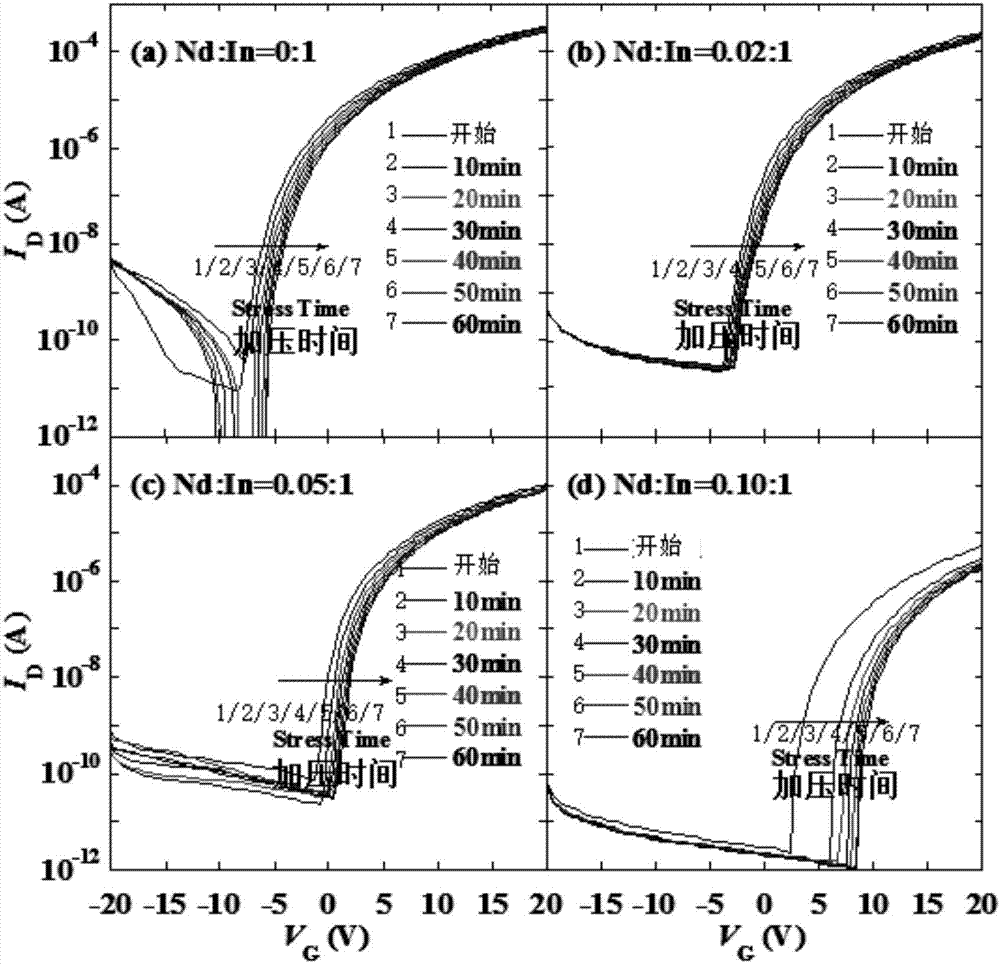

[0066] attached figure 1 Shows the different x prepared in this embodiment (x=0 represents undoped In 2 o 3 ) X-ray diffraction (XRD) pattern of the thin film, it can be seen that when the amount of Nd doped is small (x=0.02), In 2 o 3 The lattice structure of is well maintained, indicating that a small amount of Nd will not seriously damage the In 2 o 3 lattice structure. But when the amount of doped Nd is more (x≥0.05), In 2 o 3 The lattice damage is severe, mainly due to the Nd 3+ If the radius is too large, excessive doping ...

Embodiment 3

[0073] A preparation method of an oxide semiconductor thin film, the chemical formula of the composition is expressed as Sc 2x In 2-2x o 3-δ , There are three options for x: 0.02, 0.05 and 0.1. The precursor solution is an aqueous solution of indium nitrate and scandium nitrate, and the film is formed by spin coating, and the annealing temperature is 230 degrees Celsius.

[0074] attached Figure 4 Shows the different x prepared in this embodiment (x=0 represents undoped In 2 o 3 ) of the X-ray diffraction (XRD) pattern of the film, it can be seen that almost no In 2 o 3 The lattice structure of , which is mainly due to the Sc 3+ The radius of In 3+ The radii are similar and cause almost no lattice expansion.

[0075] The prepared thin film is used for the channel layer of the thin film transistor, with Figure 5The transfer characteristic curves of the aforementioned thin film transistors (TFTs) based on different Sc contents x are shown, and the performance paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com